Abstract

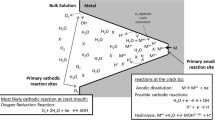

Mechanisms and kinetics of metal-induced embrittlement, hydrogen-embrittlement, and stress-corrosion cracking are discussed, and long-standing controversies are addressed by reviewing critical observations. Recommendations are also made regarding further work (including repetition of previous work using more advanced measurement and characterisation techniques) that should be carried out in order to resolve some of the contentious issues. The evidence to date suggests that adsorption-based mechanisms, involving weakening of substrate interatomic bonds so that dislocation emission or decohesion is facilitated, accounts for embrittlement in many systems. Embrittling adsorbed species include some metal atoms, hydrogen, and complex ions produced by de-alloying. Other viable mechanisms of embrittlement include those based on (1) dissolution of anodic grain-boundary regions, and (2) decohesion at grain boundaries owing to segregated hydrogen and impurities. The hydrogen-enhanced localised-plasticity mechanism, based on solute hydrogen facilitating dislocation activity in the plastic zone ahead of cracks, makes a contribution in some cases, but is relatively unimportant compared with these other mechanisms for most fracture modes. The film-induced cleavage mechanism, proposed especially for stress-corrosion cracking in systems involving de-alloying at crack tips, is questionable on numerous grounds, and is probably not viable. Rate-controlling processes for environmentally assisted cracking are not well established, except for solid-metal induced embrittlement where surface self-diffusion of embrittling atoms to crack tips controls cracking kinetics. In some systems, adsorption kinetics are probably rate-controlling for liquid-metal embrittlement, hydrogen-environment embrittlement, and stress-corrosion cracking. In other cases, rate-controlling processes could include the rate of anodic or cathodic reactions at and behind crack tips (responsible for producing embrittling species such as hydrogen) and rates of hydrogen diffusion ahead of cracks.

Similar content being viewed by others

Notes

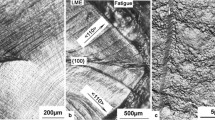

These effects of temperature are also opposite to what one would expect if dissolution was involved in crack growth. Increasing temperature decreases the severity of LME (measured from elongations or reductions of area after tensile tests) in other materials,[8–10] but the data are difficult to interpret since both crack initiation and growth are involved. For LME involving grain-boundary diffusion, increasing temperature increases the kinetics of embrittlement as would be expected.

In the original paper,[58] the dimples were described as ‘mounds’, but it is now accepted that the features were dimples[80] after it was pointed out that this was probably the case.[81] Fine dislocation cells were observed beneath the fracture surfaces in the study,[58] and voids could well have been nucleated at dislocation-cell boundaries, as has been observed by in situ TEM studies in the absence of hydrogen.[79] It was originally suggested that decohesion was involved[58] but, given that it is now accepted that fracture surfaces were dimpled, it seems more likely that AIDE predominates.[81]

Recent ultra-high resolution SEM of mating areas of opposite fracture surfaces of a steel confirms that cleavage-like facets are dimpled on a nanoscale (15–20 nm diameter and 1–5 nm depth). See Ref. [82].

Linear extrapolation of diffusion data for Ni appears to be reasonable down to at least 123 K (−150 °C), based on magnetic-relaxation measurements of jump frequencies at 173 K to 123 K (−100 °C to −150 °C), and comparisons with jump frequencies calculated from diffusion measurements at high temperatures.[88] Linear extrapolation to even lower temperatures is also probably valid since quantum-tunnelling effects, leading to diffusion faster than predicted from linear extrapolation of high-temperature diffusion data, appear not to be significant for fcc metals (unlike bcc metals). The difference between fcc and bcc metals probably occurs due to the greater distance (by a factor of about two) between the octahedral interstitial sites of hydrogen in fcc metals and the tetrahedral interstitial sites of hydrogen in bcc metals.[88]

References

S.P. Lynch: in Stress Corrosion Cracking: Theory and Practice. V.S. Raja and T. Shoji, eds., Woodhead Publishing, Cambridge, 2011, ch. 1, pp. 3-89, and ch. 2, pp. 90-130, and references therein.

R.C. Newman: in Shreir’s Corrosion, 4th ed., vol. 2, J.A. Richardson et al., eds., Elsevier, Amsterdam, 2010, pp. 864–901.

H. Hänninen: in Comprehensive Structural Integrity, Environmentally Assisted Fracture, vol. 6, I. Milne, R.O. Ritchie, and B. Karihaloo, eds., Elsevier, Amsterdam, 2003, pp. 1–29.

T. Magnin: in Materials Science and Technology: A Comprehensive Treatment, Corrosion and Environmental Degradation, vol. 1, R.W. Cahn, P. Haasen, and E.J. Kramer, eds. (M. Schütze, vol. ed.), Wiley, New York, 2000, pp. 207–63.

R.P. Gangloff: in Comprehensive Structural Integrity, vol. 6, I. Milne, R.O. Ritchie, and B. Karihaloo, eds., Elsevier, Amsterdam, 2003, pp. 31–101.

S.P. Lynch: in Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, ch. 9, vol. 1, R.P. Gangloff and B. Somerday eds., Woodhead, U.K., 2012, pp. 274–46, and references therein.

M.H. Kamdar: Prog. Mater. Sci., 1973, vol. 15, pp. 289-374.

N.S. Stoloff: in Embrittlement by Liquid and Solid Metals, M.H. Kamdar, ed., Met. Soc. AIME, New York, 1984, pp. 3–26, and other papers in these proceedings.

S.P. Lynch: Materials. Characterization, 1992, vol.28, pp.279-289, and references therein.

B. Joseph, M. Picat, and F. Barbier: Eur. Phys. J. AP, 1999, vol.5, pp. 19-31.

J. Luo, H. Cheng, K. M. Asl, C. J. Kiely, and M.P. Harmer: Science, 2011 (Sept.), vol. 333, pp.1730-1733.

E. Pereiro-López, W. Ludwig, and D. Bellet: Acta Mater., 2004, vol.52, pp.321-332.

N. Marié, K. Wolski, and M. Biscondi: Scripta Mater., 2000, vol.43, pp. 943-949.

K.Ina and H. Koizumi: Mater.Sci. Engng A, 2004, vol.387-389, pp. 390-394.

E.E. Glickman: Metall. and Mater. Trans. A, 2011, vol. 42A, 250-266.

S.P. Lynch: Scripta Metall, 1984, vol.18, 509-513.

D.N. Fager and W.F. Spurr: Corrosion, 1970, vol.26, pp. 409-419.

S.P. Lynch: Mater. Sci. Engng, 1989, vol. A108, pp. 203-212.

S.P. Lynch: Acta Metall., 1981, vol.29, pp. 325-340.

S.P. Lynch: Mater. Sci. Engng, 1985, vol. 72, pp. L33-L37.

S.P. Lynch: Acta Metall., 1984, vol.32, pp. 79-90.

S.P. Lynch: J. Mater. Sci., 1986, vol.21, pp.692-704.

S.P. Lynch and P. Trevena: Corrosion, 1988, vol.44, pp. 113-124.

S.P. Lynch: Acta Metall, 1988, vol. 20, Overview No. 74, pp. 2639–61, and references therein.

O. Yu. Kolesnychenko, R. de Kort, and H. van Kempen: Surf. Sci. 2001, vol. 490, L573–78.

S.P. Lynch, B.C. Muddle, and T. Pasang: Philos. Mag. 2002, vol. 82, pp.3361-3373.

S. M. Bruemmer and L. E. Thomas: Surface and Interface Analysis, 2001, vol.31, pp.571-581.

L. E. Thomas and S. M. Bruemmer: Corrosion, 2000, vol.56, pp.572-587.

Y. Takahashi, M. Tanaka, K. Higashida, H. Noguchi: Scripta Mater. 2009, vol.61 pp.145-148.

Y. Takahashi, M. Tanaka, K. Higashida, K. Yamaguchi, H. Noguchi: Acta Mater., 2010, vol. 58, pp.1972-1981.

Y. Takahashi, H. Nishikawa, Y. Oda, H. Noguchi: Mater. Lett. 2010, vol.64, pp.2416-2419.

W.R. Goggin and J.W. Moberly: Trans ASM,1966, vol. 59, pp.315-323.

E.D. Sweet, S. P. Lynch, C. G. Bennett, R. B. Nethercott, and I. Musulin: Metall. and Mater. Trans. A, 1996, vol.27A, pp.3530-3541.

F. A. Shunk and W. R. Warke: Scripta Metall., 1974, vol.8, pp.519-526.

S.P. Lynch: Unpublished Work, 1980.

J. Li, A.H.W. Ngan, and P. Gumbsch: Acta Mater., 2003, vol. 51, pp.5711-5742.

S. Ogata, Y. Umeno, and M. Kohyama: Modell. Simul. Mater. Sci. Eng. 2009, vol. 17, p. 013001.

O.N. Mryasov, and A.J. Freeman: Mater. Sci. Eng., 1999, vol.A269, pp. 80-93.

A.K. Nair, D.H. Warner, R.G. Hennig, and W.A. Curtin: Scripta Mater., 2010, vol. 63, pp. 1212-1215.

P. Gordon: Metall. Trans A, 1978, vol. 9A, pp.267-273.

R. E. Clegg: Engng. Frac. Mech., 2001, vol.68, pp. 1777-1790.

M.O. Speidel: in The Theory of Stress Corrosion Cracking in Alloys. J.C. Scully, ed., NATO, Brussels, 1971, pp. 289–344.

J.A. Feeney and M.J. Blackburn: in The Theory of Stress Corrosion Cracking in Alloys. J.C. Scully, ed., NATO, Brussels, 1971, pp. 355–398.

J.A. Kapp: in Embrittlement by Liquid and Solid Metals, M.H. Kamdar, ed., Met. Soc. AIME, New York, 1984, pp. 117–31.

R.E. Clegg and P.D. King: in Damage and Fracture Mechanics: Computer Aided Assessment and Control, A. Carpinteri and C.A. Brebbia, eds., 1998, pp. 557–564.

S.P. Lynch: in Environmental Degradation of Materials in Aggressive Environments, M.R. Louthan, Jr., R.P. McNitt, and R.D. Sisson, Jr., eds., Virginia Polytechnic Inst., 1981, pp. 229–244.

Z. Hadjem-Hamouche, T. Auger, and I. Guillot: Corros. Sci., 2009, vol.51, pp.2580-2587.

D.A. Wheeler, R.G. Hoagland, and J.P. Hirth: Corrosion, 1989, vol. 45, pp.207-212.

J.T. Lukowski D.B. Kasul, L.A. Heldt, and C.L. White: Scripta Metall Mater., 1990, vol.24, pp.1959-1964.

S.P. Lynch: Mater. Sci. Eng. A. 2007, vol.468-470, pp.74-80.

A. Pundt and R. Kirchheim: Annual Rev. Mater. Res., 2006, vol.36, pp.555-608.

A.A. Pisarev: in Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, ch. 1, vol. 2, R.P. Gangloff and B. Somerday, eds., Woodhead, U.K., 2012, pp. 3–26.

R.A. Oriani: Corrosion, 1987, vol. 43, pp. 390-397.

S.P. Lynch: in Hydrogen Effects on Mechanical Behavior and Corrosion Deformation Interactions, N.R. Moody et al., eds., TMS, Warrendale, PA, 2003, pp. 449–466.

I.M. Robertson, D. Lillig, and P.J. Ferreira: in Effects of Hydrogen on Materials, B.P. Somerday, P. Sofronis, and R. Jones, eds., ASM International, 2009, pp. 22–37.

Z. Sun, C. Moriconi, G. Beoit, D. Halm, and G. Henaff: Metall. Mater. Trans. A, DOI: 10.1007/s11661-012-1133-5.

M. Dadfarnia, P. Novak, D.C. Ahn, J.B. Liu, P. Sofronis, D.D. Johnson, and I.M. Robertson: Adv. Mater. 2010, vol. 22, pp. 1128-1135.

M.L. Martin, I.M. Robertson, P. Sofronis: Acta Mater., 2011, vol.59, pp.3680-3687.

M.L. Martin, B.P. Somerday, R.O. Ritchie, P. Sofronis, and I.M. Robertson: Acta Mater., 2012, vol.60, pp.2739-2745.

J.W. Davenport and P.J. Estrup: in The Chemical Physics of Solid Surfaces and Heterogeneous Catalysis, D.A. King and D.P. Woodruff, eds., Elsevier, Amsterdam, 1990, vol. 3, pp. 1–37.

T.E. Fischer: in Advanced Techniques for Characterizing Hydrogen in Metals, N.F. Fiore and B.J. Berkowitz, eds., Met. Soc. AIME, 1982, pp. 135–48.

K. Christmann: Progress in Surface Science, 1995, vol.48, 15-26.

E. Protopopoff and P. Marcus: in Corrosion Mechanisms in Theory and Practice, 2nd edn, P. Marcus, ed., Marcel Dekker, New York, 2002, pp. 53–96.

J. Oudar: in Corrosion Mechanisms in Theory and Practice, 2nd edn, P. Marcus, ed., Marcel Dekker, New York, 2002, pp. 19–51.

W. Moritz, R.J. Behm, G. Ertl, G. Kleinle, V. Penka, W. Reimer, and M. Skottke: in The Structure of Surfaces II, Springer, New York, 1988, pp. 207–13.

Y. Kuk, P.J. Silverman and H.Q. Nguyen: Phys. Rev. Lett., 1987, vol.59, (No. 13), pp.1452-1455.

R. Stumpf: Phys. Rev. Lett., 1997, vol.78, (No. 23), pp.4454-4457.

M.S. Daw and M.I. Baskes: in Chemistry and Physics of Fracture, R.H. Jones and R.M. Latanision, eds., Martinus Nijhoff, The Netherlands, 1987, pp. 196–18.

R.G. Hoagland and H.L. Heinisch: J. Mater. Res., 1992, vol.7, pp.2080-2088.

K.N. Solanki, D.K. Ward, and D.J. Bammann: Metall. Mater. Trans. A, 2011, vol. 42A, pp.340-347.

G. Lu, Q. Zhang, N. Kioussis, and E. Kaxiras: Phys. Rev. Lett. 2001, vol. 87, p. 9:095501-1.

S. Taketomi, R. Matsumoto, N. Miyazaki: Int. J. Mech. Sci., 2010, vol. 52, pp. 334-338.

R. Kirchheim: Scripta Mater., 2010, vol. 62, pp. 67-70.

J.A. Clum: Scripta Metall., 1975, vol. 9, pp.51-58.

I.M. Robertson: Eng. Fract. Mech., 2001, vol.68, pp.671-692.

H. Vehoff and W. Rothe: Acta Metall 1983, vol. 31, Overview No. 30, pp. 1781–1793.

M. Nagumo: Mater. Sci. and Tech., 2004, vol. 20, pp. 940-950.

G. Lu and E. Kaxiras: Phys. Rev. Lett., 2005, vol. 94, pp. 155501-1-155501-4.

K. Jagannadham and H.G.F. Wilsdorf: Mater. Sci. and Engng, 1986, vol. 81, pp. 273-292.

I.M. Robertson, M.L. Martin, and J. Fenske: in Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, R.P. Gangloff and B. Somerday, eds., ch. 9, vol. 1, Woodhead, U.K., 2012, pp. 166–206.

S.P. Lynch: Scripta Mater., 2011, vol. 65, pp. 851–54.

T. Neejay, R. Srinivasan, and Ju Li: Acta Mater., 2012, vol. 60, pp. 5160–71.

C.E. Price and R.S. Fredell: Metall. Trans A, 1986, vol. 17A, pp. 889-898.

H.H. Johnson: in Hydrogen in Metals, I.M. Bernstein and A.W. Thompson, eds., ASM, 1974, pp. 35–49.

M.H. Kamdar: Embrittlement of Nickel by Gaseous Hydrogen, 3D10, 2 nd Inter, Congress on Hydrogen in Metals, Pergamon Press, 1977.

H. Wipf: Topics in Applied Physics, vol. 73, ch .3 1997, pp. 51–91.

W. Wei: Crack Kinetics in the Nickel-Hydrogen System, Ph.D. Thesis, University of Illinois at Urbana-Champaign, 1984.

H. Grabert and H.R. Schober: Topics in Applied Physics, vol. 73, ch. 2, 1997, pp. 5–49.

R.M. Latanision: in Surface Effects in Crystal Plasticity, R.M. Latanision and J.T. Fourie, eds., NATO Advanced Study Inst. Series E: Applied Science-No. 17, Noordhoff Int. Publ., 1977, pp. 3–47.

C.D. Beachem: Metall. Trans., 1972, vol. 3, pp.437-451.

C.D. Beachem: Personal Communication, late 1970s.

H.K. Birnbaum: in Hydrogen Effects on Materials Behavior, N.R. Moody and A.W Thompson, eds., TMS, 1990, pp. 639–658, and discussion pp. 659–660.

H.K. Birnbaum, I.M. Robertson, P. Sofronis, and D. Teter: in Corrosion-Deformation Interactions, T. Magnin, ed., Inst. of Mat., London, 1997, pp. 172–195, and references therein.

H.K. Birnbaum and P. Sofronis: Mater. Sci. Eng., 1994, vol.A176, pp.191-202.

N.R. Moody and F.A. Greulich: Scripta Metall., 1985, vol. 19, pp.1107-1111.

N.R. Moody, R.E. Stoltz, and W. Perra: Metall. Trans. A, 1987, vol. 18A, pp. 1469-1482.

P.D. Hicks and C.J. Altstetter: Metall. Trans. A, 1992, vol. 32A, pp. 237-249.

K.A. Nibur, B.P. Somerday, D.K. Balch, and C. San Marchi: Acta Mater., 2009, vol. 57, pp. 3795-3809.

R. Jones: in Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, ch. 9, vol. 2, R.P. Gangloff and B. Somerday, eds., Woodhead, U.K., 2012, pp. 471–484.

D.C. Ahn, P. Sofronis, and R.H. Dodds Jr.: Int. J. of Hydrogen Energy, 2007, vol. 32, pp. 3734-3742.

D.C. Ahn, P. Sofronis, and R.H. Dodds Jr.: Int. J. Fract., 2007, vol. 145, pp. 135-157.

T. Tabata and H.K. Birnbaum: Scripta Metall.,1983, vol. 17, pp. 947-950.

G.M. Bond, I.M. Robertson, and H.K. Birnbaum: Scripta Metall., 1986, vol. 20, pp. 653-658.

H.K. Birnbaum: Scripta Metall. Mater., 1994, vol. 31, pp. 149-153.

D.F. Teter, I.M. Robertson, and H.K. Birnbaum: Acta Mater., 2001, vol.49, pp.4313-4323.

C.D. Beachem and G.R. Yoder: Metall. Trans., 1973, vol. 4, pp. 1145-1153.

R.H. Jones; Acta Metall. Mater., 1990, vol. 38, pp. 1703-1718.

C.J. McMahon, Jr.: Eng. Frac. Mech. 2001, vol. 68. pp. 773–88.

S.P. Lynch: Mater. Forum, 1988, vol.11, pp. 268-283.

W.A. McInteer, A.W. Thompson, and I.M. Bernstein: Acta Metall., 1980, vol. 28, pp. 887-894.

I.M. Robertson and H.K. Birnbaum: Scripta Metall., 1984, vol. 18, pp. 269-274.

A.H. Windle and G.C. Smith: Metal Sci. J., 1970, vol. 4, pp. 136-144.

G.A. Young and J.R. Scully: in Hydrogen Effects on Materials Behavior and Corrosion Deformation Interactions, N.R. Moody et al., eds., TMS, 2003, pp. 893–907.

A. Turnbull: in Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, ch. 4, vol. 2, R.P. Gangloff and B. Somerday, eds., Woodhead, U.K., 2011, pp. 89–128.

B. Cox: J. of Nuclear Materials, 1990, vol.170, 1-23.

S.P. Lynch: Scripta metall., 1984, vol.18, pp.321-326.

M.B. Hintz: Scripta Metall., 1985, vol.19, pp.1445-1450.

R.C. Newman, T. Shahrabi, and K. Sieradzki: Scripta Metall., 1989, vol.23, pp.71-74.

M. Saito, G.S. Smith, and R.C. Newman: Corros. Sci., 1993, vol.35, pp.411-413.

A. Barnes, N.A. Senior, and R.C. Newman: Metall. and Mater. Trans. A, 2009, vol.40A, pp.58-68.

D. Kiener, W. Grosinger, G. Dehm, and R. Pippan: Acta Mater., 2008, vol.56, pp.580-592.

J.J. Lewandowski and A.L. Greer: Nature Materials, 2006, vol.5, pp.15-18.

C.J. Gilbert, J.W. Ager III, V. Schroeder, R.O. Ritchie, J.P. Lloyd, and J.R. Graham: Appl. Phys. Letters, 1999, vol.74, pp.3809-3811.

U. Bertocci, F.I. Thomas, and E.N. Pugh: Corrosion, 1984, vol.40, pp.439-440.

D.M. Kolb: Surface Science, 2002, vol.500, pp.722-740.

D.M. Kolb: Progress in Surf. Sci., 1996, vol.51, pp.109-173.

O.M. Magnussen: Chem. Rev., 2002, vol.102, pp.679-725.

H. Matsushima, A. Taranovskyy, C. Haak, Y. Gründer, and O.M. Magnussen: J. Am. Chem. Soc., 2009, vol.131, pp.10362-10363.

H. Vehoff, H. Stenzel, and P. Neumann: Z. Metallkde, 1987, vol.78, pp.550-556.

K. Sieradzki and R.C. Newman: Philos. Mag. A, 1985, vol.51, pp.95-132.

R.E. Ricker, J.L. Fink, J.S. Harris, and A.J. Shapiro: Scripta Metall. Mater., vol.26, 1019-1023, 1992.

J.R. Galvele: Corros. Sci., 1987, vol.27, pp.1-33.

T. Livne, X. Chen, and W.W. Gerberich: Scripta Metall., 20, 659-662, 1986.

R.P. Gangloff and R.P. Wei: Metall. Trans. A, 8A, 1043-1053, 1977.

R.P. Wei: in Hydrogen Effects on Material Behavior, N.R. Moody and A.W. Thompson, eds., TMS, 1990, pp. 789–813.

M. Lu, P.S. Pao, T.W. Weir, G.W. Simmons, and R.W. Wei: Metall. Trans. A, 1981, vol. 12A, pp. 805-811.

C.M. Ransom and P.J. Ficalora: Metall. Trans. A., 11A, 801-807,1980.

R.W. Pasco and P.J. Ficalora: Acta Metall., 31, pp. 541-558, 1983.

M.R. Shanabarger: in Advanced Techniques for Characterizing Hydrogen in Metals, N.F. Fiore and B.J. Berkowitz, eds., Met. Soc. AIME, 1982, pp. 155–169.

S.P. Knight, N.Birbilis, B.C. Muddle, A.R. Trueman, and S.P. Lynch: Corros. Sci., 2010, vol. 52, pp. 4073-4080.

A. Turnbull: in Environmentally Assisted Cracking: Predictive Methods for Risk Assessment and Evaluation of Materials, Equipment, and Structures, R.D. Kane, ed., ASTM STP 1401, 2000, pp. 23–39.

S.P. Lynch: in Corrosion-Deformation Interactions, T. Magnin and J.M. Gras, eds., Les Editions de Physique Les Ulis, 1993, pp. 401–13.

R.M.N. Pelloux: in Fracture 1969, Proc. 2 nd Int. Conf. on Fracture, Brighton, Chapman and Hall, London, 1969, pp. 731–44.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 15, 2011.

Rights and permissions

About this article

Cite this article

Lynch, S.P. Mechanisms and Kinetics of Environmentally Assisted Cracking: Current Status, Issues, and Suggestions for Further Work. Metall Mater Trans A 44, 1209–1229 (2013). https://doi.org/10.1007/s11661-012-1359-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1359-2