Abstract

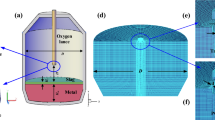

This article summarizes the outcome of research work carried out to improve the performance of the oxygen lance in the LD steelmaking process. It is stated that the lack of control of the foamy slag and the augmentation of interfacial area creation between the slag and metal are the major hindrances in running the process effectively for improved turn-down steel quality. The ineffectiveness of the existing design in producing liquid metal droplets in the presence of slag foam is explained. In order to augment the droplet generation, a new oxygen lance with a central subsonic nozzle through which flow can be controlled has been introduced and its blowing performances studied using numerical and water model studies. The jet characteristics studied in the numerical simulations show no jet coalescence. The interferences of the jets with the bath have further been analyzed by hydrodynamic model studies. It has been found that the droplet generation rate improves significantly due to the presence of the central jet. Further, it has been observed that controlling the flow rate through the central hole can be used as an effective process control tool.

Similar content being viewed by others

REFERENCES

A. Chatterjee, N.O. Lindfors, J.A. Wester: Ironmaking and Steelmaking, 1976, vol. 3, p. 21

D.J. Price: Process Engineering of Pyrometallurgy, M.J. Jones, ed., Institute of Mining and Metallurgy, London, 1974, p. 8

N. Standish, Q.L. He: ISIJ Int., 1989, vol. 30, p. 455

Q.L. He, N. Standish: ISIJ Int., 1990, vol. 30, p. 305

C.K. Lee, J.H. Neilson, and A. Gilchrist: Ironmaking Steelmaking, 1977, No. 6, p. 329

S.K. Sharma, J.W. Hlinka, and D.W. Kern: Iron Steelmaker, 1977, p. 7

R.B. Banks, D.V. Chandrasekhara: J. Fluid Mech., 1963, vol. 15, p. 13

D.H. Wakelin: Ph.D. Thesis, University of London, London, 1966

N.A. Molloy: J. Iron Steel Inst., 1970, p. 943

Subagyo, G.A. Brooks, K.S. Koley, and G.A. Irons: ISIJ Int., 2003, vol. 43, p. 983

R.D. Pehlke, W.F. Porter, R.F. Urban, J.M. Gaines: BOF Steelmaking, Introduction, Theory and Design, Part I, ISS, Warrendale, PA, 1982, p. 597

International Patent No. PCT/IN06/00153 filed on 4th May, 2006, based on Indian Patent Application No. 1023/KOL/05

Fluent’s Users Guide, Fluent Inc., Lebanon, 2004

Y. Tago, Y. Higuchi: ISIJ Int., 2003, vol. 43 (2), p. 209

P. Nillers: Past Present Future of Steelmaking in Europe BHM, 1992, vol. 137, p. 279

J. Nagai, H. Take, K. Nakanishi, T. Yamamota, R. Tachibana, Y. Iida, H. Yamada, and H. Omari: “Metallurgical Characteristics of Combined Blown Converters,” Kawasaki Steel Technical Report No. 6, Kawasaki Steel, 1982

ACKNOWLEDGMENTS

The authors thank the management of Tata Steel for giving permission to publish this work. They are thankful to all who have directly or indirectly contributed toward making the study at the Institute of Fluid Mechanics (LSTM, Erlangen, Germany). One of the authors (SNL) thanks Mr. Buelant Uensal, who helped during the setup of the LD vessel model.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 23, 2006.

Rights and permissions

About this article

Cite this article

SAMBASIVAM, R., LENKA, S., DURST, F. et al. A New Lance Design for BOF Steelmaking. Metall Mater Trans B 38, 45–53 (2007). https://doi.org/10.1007/s11663-006-9004-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-9004-3