Abstract

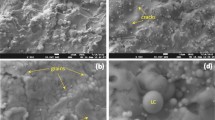

The aim of this work is to improve the corrosion resistance of AISI D3 steel surfaces using a [Ti-Al/Ti-Al-N] n multilayer system deposited with different periods (Λ) and bilayer numbers (n), via magnetron co-sputtering pulsed d.c. procedure, from a metallic (Ti-Al) binary target. The multilayer coatings were characterized by cross-sectional scanning electron microscopy that showed the modulation and microstructure of the [Ti-Al/Ti-Al-N] n multilayer system. The composition of the single Ti-Al and Ti-Al-N layer films was studied via x-ray photoelectron spectroscopy, where typical signals for Ti2p1/2, Ti2p, N1s, and Al2p3/2 were detected. The electrochemical properties were evaluated by electrochemical impedance spectroscopy and Tafel polarization curves. The optimal electrochemical behavior was obtained for the [Ti-Al/Ti-Al-N] n multilayered period of Λ = 25 nm (100 bilayers). At these conditions, the maximum polarization resistance (1719.32 kΩ cm2) and corrosion rate (0.7 μmy) were 300 and 35 times higher than that of uncoated AISI D3 steel substrate (5.61 kΩ cm2 and 25 μmy, respectively). Finally, scanning electron microscopy was used to analyze the [Ti-Al/Ti-Al-N] n multilayered surface after the corrosive attack. The improvement effects in the electrochemical behavior of the AISI D3 coated with the [Ti-Al/Ti-Al-N] n multilayered coatings could be attributed to the number of interfaces that act as obstacles for the inward and outward diffusions of Cl− ions, generating an increment in the energy or potential required for translating the corrosive ions across the coating/substrate interface.

Similar content being viewed by others

References

L. Ipaz, J.C. Caicedo, N. Alba de Sánchez, G. Zambrano, and M.E. Gómez, Tribological Characterization of Cr/CrN Films Deposited on to RUS-3 Steel by d.c. Magnetrón Sputtering Method, Rev. LatinAm. Metal. Mater., 2010, 30(1), p 82–88

F. Vacandio, Y. Massiani, P. Gravier, S. Rossi, P.L. Bonora, and L. Fedrizzi, Improvement of the Electrochemical Behaviour of AlN Films Produced by Reactive Sputtering Using Various Under-Layers, Electrochim. Acta, 2001, 46, p 3827–3834

J.E. Sanchéz, O.M. Sánchez, L. Ipaz, W. Aperador, J.C. Caicedo, C. Amaya, M.A. Hernández Landaverde, F. Espinoza Beltran, J. Muñoz-Saldaña, and G. Zambrano, Mechanical, Tribological, and Electrochemical Behavior of Cr1-xAlxN Coatings Deposited by r.f. Reactive Magnetron Co-sputtering Method, Appl. Surf. Sci., 2010, 256, p 2380–2387

J.C. Caicedo, L. Yate, G. Cabrera, W. Aperador, G. Zambrano, and P. Prieto, Effect of Negative Bias Voltage on Mechanical and Electrochemical Nature in Ti-W-N Coatings, J. Mater. Sci., 2011, 46, p 1244–1252

J. Romero, J. Esteve, and A. Lousa, Period Dependence of Hardness and Microstructure on Nanometric Cr/CrN Multilayers, Surf. Coat. Technol., 2004, 188, p 338

B.M. Clemens, H. Hung, and S.A. Barnett, Structure and Strength of Multilayers, MRS Bull., 1999, 24–2, p 20

W. Aperador, J.C. Caicedo, C. España, G. Cabrera, and C. Amaya, Bilayer Period Effect on Corrosion-Erosion Resistance for [TiN/AlTiN]n Multilayered Growth on AISI1045 Steel, J. Phys. Chem. Solids, 2010, 71, p 1754–1759

L. Yate, J.C. Caicedo, A. Hurtado Macias, F.J. Espinoza-Beltrán, G. Zambrano, J. Muñoz-Saldaña, and P. Prieto, Composition and Mechanical Properties of AlC, AlN and AlCN Thin Films Obtained by r.f. Magnetron Sputtering, Surf. Coat. Technol., 2009, 203, p 1904–1907

J.H. Lee, S.H. Ahn, and J.G. Kim, Effect of Al Additions in WC-(Cr1-xAlx)N Coatings on the Corrosion Resistance of Coated AISI, D2 Steel in a Deaerated 3.5 wt.% NaCl Solution, Surf. Coat. Technol., 2005, 190, p 417–427

J.C. Caicedo, C. Amaya, G. Cabrera, J. Esteve, W. Aperador, M.E. Gómez, and P. Prieto, Corrosion Surface Protection by Using Titanium Carbon Nitride/Titanium-Niobium Carbon Nitride Multilayered System, Thin Solid Films, 2011, 519, p 6362–6368

P.V. Nazarenko, A.G. Molyar, I.E. Polishchuk, O.G. Yachinskaya, and A.A. Il’in, Structural Defects and the Electrochemical Properties of Nitride Coatings, Met. Sci. Heat Treat., 1990, 32(4), p 305

C. Schönjahn, M. Bamford, L.A. Donohue, D.B. Lewis, S. Forder, and W.-D. Münz, The Interface Between TiAlN Hard Coatings and Steel Substrates Generated by High Energetic Cr+ Bombardment, Surf. Coat. Technol., 2000, 125, p 66–70

X.X. Qu, Q.X. Zhang, Q.B. Zou, N. Balasubramanian, P. Yang, and K.Y. Zeng, Characterization of TiAl Alloy Films for Potential Application in MEMS Bimorph Actuators, Mater. Sci. Semicond. Process., 2002, 5, p 35–38

S.-K. Tien and J.-G. Duh, Comparison of Microstructure and Phase Transformation for Nanolayered CrN/AlN and TiN/AlN Coatings at Elevated Temperatures in Air Environment, Thin Solid Films, 2006, 515, p 1097

G.G. Stoney, The Tension of Metallic Films Deposited by Electrolysis, Proc. R. Soc. Lond. A, 1909, 82, p 172–175

G.S. Fox-Rabinovich, K. Yamamoto, A.I. Kovalev, S.C. Veldhuis, L. Ning, L.S. Shuster, and A. Elfizy, Wear Behavior of Adaptive Nano-multilayered TiAlCrN/NbN Coatings Under Dry High Performance Machining Conditions, Surf. Coat. Technol., 2008, 202, p 2015–2022

P.W. Shum, Z.F. Zhou, K.Y. Li, and Y.G. Shen, XPS, AFM and Nanoindentation studies of Ti1−xAlxN films synthesized by reactive unbalanced magnetron sputtering, Mater. Sci. Eng. B., 2003, 100, p 204–213

J.F. Watts and J. Wolstenholme, An Introduction to Surface Analysis by XPS and AES, John Wiley & Sons Ltd., Chichester, England, 2003, p 73–76

P.L. Tam, Z.F. Zhou, P.W. Shum, and K.Y. Li, Structural, Mechanical, and Tribological Studies of Cr-Ti-Al-N Coating with Different Chemical Compositions, Thin Solid Films, 2008, 516, p 5725–5731

S.Y. Kim, H.W. Jang, J.K. Kim, C.M. Jeon, W.I. Park, G.-C. Yi, and J.-L. Lee, Low-Resistance Ti/Al Ohmic Contact on Undoped ZnO, J. Electron. Mater., 2002, 31, p 868

S. Badrinarayanan, S. Sinha, and A.B. Mandale, XPS Studies of Nitrogen Ion Implanted Zirconium and Titanium, J. Electron Spectrosc. Relat. Phenom., 1989, 49, p 303

Y.M. Shulga, V.N. Troizkii, M.I. Aivasov, Y.G. Borodko, and J. Neorg, X-ray Photoelectronspectra of Scandium, Titanium, Vanadium and Chromium Mononitrides, Russ. J. Inorg. Chem., 1976, 21, p 2621

H. Miya, M. Izumi, S. Konagata, and T. Takahagi, Analysis of Chemical Structures of Ultrathin Oxynitride Films by X-Ray Photoelectron Spectroscopy and Secondary Ion Mass Spectrometry, Jpn. J. Appl. Phys., 2003, 42, p 1119–1122

J.A. Taylor and J.W. Rabalais, Reaction of N2 + Beams with Aluminum Surfaces, J. Chem. Phys., 1981, 75, p 1735

J.R. Lindsay, H.J. Rose, Jr., W.E. Swartz, P.H. Watts, Jr., and K.A. Rayburn, X-ray Photoelectron Spectra of Aluminum Oxides: Structural Effects on the “Chemical Shift”, Appl. Spectrosc., 1973, 27, p 1–5

J.E.B. Randles, Kinetics of Rapid Electrode Reactions, Discuss. Faraday Soc., 1947, 1, p 11–19

E. Söderlund and P. Ljunggren, Formability and Corrosion Properties of Metal/Ceramic Multilayer Coated Strip Steels, Surf. Coat. Technol., 1998, 110, p 94–104

M. Fenker, M. Balzer, H.A. Jehn, H. Kappl, J.-J. Lee, K.-H. Lee, and H.-S. Park, Improvement of the Corrosion Resistance of Hard Wear Resistant Coatings by Intermediate Plasma Etching or Multilayered Structure, Surf. Coat. Technol., 2002, 150, p 101–106

H.A. Jehn, Improvement of the Corrosion Resistance of PVD Hard Coating-Substrate Systems, Surf. Coat. Technol., 2000, 125, p 212

V.K. William Grips, C. Barshilia, V. Ezhil Selvi, Kalavati, and K.S. Rajam, Electrochemical Behavior of Single Layer CrN, TiN, TiAlN Coatings and Nanolayered TiAlN/CrN Multilayer Coatings Prepared by Reactive Direct Current Magnetron Sputtering, Thin Solid Films, 2006, 514, p 204

W. Tato and D. Landolt, Electrochemical Determination of the Porosity of Single and Duplex PVD Coatings of Titanium and Titanium Nitride on Brass, J. Electrochem. Soc., 1998, 145, p 4173–4181

K.-L. Chang, S.-C. Chung, S.-H. Lai, and H.-C. Shih, The Electrochemical Behavior of Thermally Oxidized CrN Coatings Deposited on Steel by Cathodic Arc Plasma Deposition, Appl. Surf. Sci., 2004, 236, p 406

H. Altun and S. Sen, The Effect of DC Magnetron Sputtering AlN Coatings on the Corrosion Behaviour of Magnesium Alloys, Surf. Coat. Technol., 2005, 197, p 193

Y.H. Yoo, D.P. Le, J.G. Kim, S.K. Kim, and P.V. Vinh, Corrosion Behavior of TiN, TiAlN, TiAlSiN Thin Films Deposited on Tool Steel in the 3.5 wt.% NaCl Solution, Thin Solid Films, 2008, 516, p 3544–3548

Acknowledgments

This research was supported by “El patrimonio Autónomo Fondo Nacional de Financiamiento para la Ciencia, la Tecnología y la Innovación Francisco José de Caldas” under contract RC-No. 275-2011 with The Center of Excellence for Novel Materials (CENM). Moreover, the authors acknowledge the Serveis Científico-Técnics of the Universitat de Barcelona and the Centro de Investigación y de Estudios Avanzados del IPN, Unidad Querétaro, México, for XPS, SEM, and XRD analysis. L. Ipaz thanks COLCIENCIAS for the doctoral fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ipaz, L., Aperador, W., Caicedo, J.C. et al. Improvement of the Electrochemical Behavior of Steel Surfaces Using a [Ti-Al/Ti-Al-N] n Multilayer System. J. of Materi Eng and Perform 22, 1471–1480 (2013). https://doi.org/10.1007/s11665-012-0426-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0426-6