Abstract

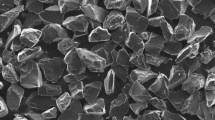

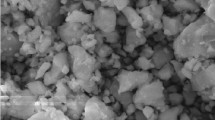

The aim of this paper was to evaluate the effect of different dispersion methodologies on mechanical properties of the aluminum-silicon (AlSi) composites reinforced by multi-walled carbon nanotubes (MWCNTs) coated with Ni. Different mixing procedures of MWCNTs with AlSi powder were tested, and AlSi-CNT composites were produced by hot pressing—powder metallurgy technique. The shear tests were performed to get the mechanical properties. Scanning electron microscopy with x-ray energy dispersive spectroscopy analysis and thermal analysis was used to investigate the microstructure of AlSi-CNT composites, interface reactions, and fracture morphology after shear tests. The experimental results proved that an improvement of dispersion of CNTs was achieved by using a combination of different mixing processes.

Similar content being viewed by others

References

X. Lu and Z. Hu, Mechanical Property Evaluation of Single-Walled Carbon Nanotubes by Finite Element Modeling, Composites B, 2012, 43, p 1902–1913

M.D. Ganji, A. Fereidoon, M. Jahanshahi, and M.G. Ahangari, Investigation of the Mechanical Properties of Multi-walled Carbon Nanotubes Using Density Functional Theory Calculations, J. Comput. Theor. Nanos., 2012, 9, p 980–985

M.J. O’Connell, Carbon Nanotubes: Properties and Applications, CRC Press Taylor & Francis Group, Boca Raton, 2006

Y.Y. Huang and E.M. Terentjev, Dispersion of Carbon Nanotubes: Mixing, Sonication, Stabilization, and Composite Properties, Polymers, 2012, 4, p 275–295

A. Esawi and K. Morsi, Dispersion of Carbon Nanotubes (CNTs) in Aluminum Powder, Composites A, 2007, 38, p 646–650

C. Deng, X. Zhang, D. Wang, Q. Lin, and A. Li, Preparation and Characterization of Carbon Nanotubes/Aluminum Matrix Composites, Mater. Lett., 2007, 61, p 1725–1728

R. Perez-Bustamante, C.D. Gomez-Esparz, I. Estrada-Guel, M. Miki-Yoshida, L. Licea-Jimenez et al., Microstructural and Mechanical Characterization of Al-MWCNT Composites Produced by Mechanical Milling, Mater. Sci. Eng. A, 2009, 502, p 159–163

A.M.K. Esawi, K. Morsi, A. Sayed, A.A. Gawad, and P. Borah, Fabrication and Properties of Dispersed Carbon Nanotube-Aluminum Composites, Mater. Sci. Eng. A, 2009, 508, p 167–173

S. El-Eskandarany, Mechanical Alloying: For Fabrication of Advanced Engineering Materials, Elsevier Science, New York, 2013

C.F. Deng, D.Z. Wang, X.X. Zhang, and A.B. Li, Processing and Properties of Carbon Nanotubes Reinforced Aluminum Composites, Mater. Sci. Eng. A, 2007, 444, p 138–145

R. Perez-Bustamante, I. Estrada-Guel, W. Antunez-Flores, M. Miki-Yoshida, P.J. Ferreira, and R. Martinez-Sanchez, Novel Al-Matrix Nanocomposites Reinforced with Multi-walled Carbon Nanotubes, J. Alloys Compd., 2008, 450, p 323–326

K.G. Dassios, Carbon Nanotube-Reinforced Ceramic Matrix Composites: Processing and Properties, Ceram. Trans., 2014, doi:10.1002/9781118932995.ch15

S.R. Bakshi and A. Agarwal, An Analysis of the Factors Affecting Strengthening in Carbon Nanotube Reinforced Aluminum Composites, Carbon, 2011, 49, p 533–544

L. Ci, Z. Ryu, N.Y. Jin-Phillipp, and M. Ruehle, Investigation of the Interfacial Reaction Between Multi-walled Carbon Nanotubes and Aluminum, Acta Mater., 2006, 54, p 5367–5375

H. Kwon, M. Estili, K. Takagi, T. Miyazaki, and A. Kawasaki, Combination of Hot Extrusion and Spark Plasma Sintering for Producing Carbon Nanotube Reinforced Aluminum Matrix Composites, Carbon, 2009, 47, p 570–577

T. Laha, S. Kuchibhatla, S. Seal, W. Li, and A. Agarwal, Interfacial Phenomena in Thermally Sprayed Multiwalled Carbon Nanotube Reinforced Aluminum Nanocomposite, Acta Mater., 2007, 55, p 1059–1066

T. Laha, Y. Chen, D. Lahiri, and A. Agarwal, Tensile Properties of Carbon Nanotube Reinforced Aluminum Nanocomposite Fabricated by Plasma Spray Forming, Composites A, 2009, 40, p 589–594

K. Morsi and A. Esawi, Effect of Mechanical Alloying Time and Carbon Nanotube (CNT) Content on the Evolution of Aluminum (Al)-CNT Composite Powders, J. Mater. Sci., 2007, 42, p 4954–4959

K.S. Munir, P. Kingshott, and C. Wen, Carbon Nanotube Reinforced Titanium Metal Matrix Composites Prepared by Powder Metallurgy—A Review, Crit. Rev. Solid State Mater. Sci., 2014, doi:10.1080/10408436.2014.929521

C.D. Li, X.J. Wang, K. Wu, W.Q. Liu, S.L. Xiang, C. Ding, X.S. Hu, and M.Y. Zheng, Distribution and Integrity of Carbon Nanotubes in Carbon Nanotube/Magnesium Composites, J. Alloys Compd., 2014, 612, p 330–336

T. Premkumar, R. Mezzenga, and K.E. Geckeler, Carbon Nanotubes in the Liquid Phase: Addressing the Issue of Dispersion, Small, 2012, 8, p 1299–1313

J.S. Oh, K.H. Ahn, and J.S. Hong, Dispersion of Entangled Carbon Nanotube by Melt Extrusion, Korea Aust. Rheol. J., 2010, 22, p 89–94

W. Salas, N.G. Alba-Baena, and L.E. Murr, Explosive Shock-Wave Consolidation of Aluminum Powder/Carbon Nanotube Aggregate Mixtures: Optical and Electron Metallography, Metall. Mater. Trans. A, 2007, 38, p 2928–2935

T. Peng and I. Chang, Mechanical Alloying of Multi-walled Carbon Nanotubes Reinforced Aluminum Composite Powder, Powder Technol., 2014, 266, p 7–15

Z.D. Tao, H.R. Geng, K. Yu, Z.X. Yang, and Y.Z. Wang, Effects of High-Energy Ball Milling on the Morphology and the Field Emission Property of Multi-walled Carbon Nanotubes, Mater. Lett., 2004, 58, p 3410–3413

Q. Zhang, Carbon Nanotubes and Their Applications, CRC Taylor & Francis Group, Boca Raton, 2012

O. Carvalho, G. Miranda, D. Soares, and F.S. Silva, Carbon Nanotube Dispersion in Aluminum Matrix Composites—Quantification and Influence on Strength, Mech. Adv. Mat. Struct., 2014, doi:10.1080/15376494.2014.929766

S.R. Bakshi, D. Lahiri, and A. Agarwal, Carbon Nanotube Reinforced Metal Matrix Composites—A Review, Int. Mater. Rev., 2010, 55, p 41–64

C.M. Efraín, Carbon Nanotube-Metal Matrix Composites. Encyclopedia of Nanoscience and Nanotechnology, Dekker, Ed., 2nd ed, null, p 611–619, (Boca Raton), Taylor & Francis (2009), p 611–619

B. Munkhbayar, M. Nine, J. Jeoun, M. Bat-Erdene, H. Chung, and H. Jeong, Influence of Dry and Wet Ball Milling on Dispersion Characteristics of the Multi-walled Carbon Nanotubes in Aqueous Solution with and Without Surfactant, Powder Technol., 2013, 234, p 132–140

N. Al-Aqeeli, K. Abdullahi, C. Suryanarayana, T. Laoui, and S. Nouari, Structure of Mechanically Milled CNT-Reinforced Al-Alloy Nanocomposites, Mater. Manuf. Process., 2013, 28, p 984–990

Z.Y. Liu, S.J. Xu, B.L. Xiao, P. Xue, W.G. Wang, and Z.Y. Ma, Effect of Ball-Milling Time on Mechanical Properties of Carbon Nanotubes Reinforced Aluminum Matrix Composites, Composites A, 2012, 43, p 2161–2168

Y.B. Li, B.Q. Wei, J. Liang, Q. Yu, and D.H. Wu, Transformation of Carbon Nanotubes to Nanoparticles by Ball Milling Process, Carbon, 1999, 37, p 493–497

S. Yoshio, J. Tatami, T. Yamakawa, T. Wakihara, and K. Komeya, Dispersion of Carbon Nanotubes in Ethanol by a Bead Milling Process, Carbon, 2011, 49, p 4131–4137

B. Munkhbayar, M.J. Nine, S. Hwang, J. Kim, and K. Bae, Effect of Grinding Speed Changes On Dispersibility of the Treated Multi-walled Carbon Nanotubes in Aqueous Solution and its Thermal Characteristics, Chem. Eng. Process., 2012, 61, p 36–41

K.S. Park and J.R. Youn, Dispersion and Aspect Ratio of Carbon Nanotubes in Aqueous Suspension and Their Relationship with Electrical Resistivity of Carbon Nanotube Filled Polymer Composites, Carbon, 2012, 50, p 2322–2330

G. Pagani, M.J. Green, P. Poulin, and M. Pasquali, Competing Mechanisms and Scaling Laws for Carbon Nanotube Scission by Ultrasonication, Proc. Natl. Acad. Sci. USA, 2012, 109, p 11599–11604

A. Lucas, C. Zakri, M. Maugey, M. Schoo, Pvd Pasquali, and P. Poulin, Kinetics of Nanotube and Microfiber Scission Under Sonication, J. Phys. Chem. C, 2009, 113, p 20599–20605

J.W. Ning, J.J. Zhang, Y.B. Pan, and J.K. Guo, Fabrication and Mechanical Properties of SiO2 Matrix Composites Reinforced by Carbon Nanotube, Mater. Sci. Eng. A, 2003, 357, p 392–396

B. Safadi, R. Andrews, and E.A. Grulke, Multiwalled Carbon Nanotube Polymer Composites: Synthesis and Characterization of Thin Films, J. Appl. Polym. Sci., 2002, 84, p 660–2669

R.A. Graff, J.P. Swanson, P.W. Barone, S. Baik, D.A. Heller, and M.S. Strano, Achieving Individual-Nanotube Dispersion at High Loading in Single-Walled Carbon Nanotube Composites, Adv. Mater., 2005, 17, p 980–984

T.R. Frømyr, F.K. Hansen, and T. Olsen, The Optimum Dispersion of Carbon Nanotubes for Epoxy Nanocomposites: Evolution of the Particle Size Distribution by Ultrasonic Treatment, Nanotechnology, 2012, 2012, p 1–14

A. Ilcham, A. Srisurichan, A. Soottitantawat, and T. Charinpanitkul, Dispersion of Multi-walled Carbon Nanotubes in Poly(p-phenylene) Thin Films and Their Electrical Characteristics, Particuology, 2009, 7, p 403–407

R. George, K.T. Kashyap, R. Rahul, and S. Yamdagni, Strengthening in Carbon Nanotube/Aluminium (CNT/Al) Composites, Scr. Mater., 2005, 53, p 1159–1163

H.J. Ryu, S.I. Cha, and S.H. Hong, Generalized Shear-Lag Model for Load Transfer in SiC/Al Metal-Matrix Composites, J. Mater. Res., 2003, 18, p 2851–2858

S.J. Yoo, S.H. Han, and W.J. Kim, Strength and Strain Hardening of Aluminum Matrix Composites with Randomly Dispersed Nanometer-Length Fragmented Carbon Nanotubes, Scr. Mater., 2013, 68, p 711–714

H.J. Ryu, S.I. Cha, and S.H. Hong, Generalized Shear-Lag Model for Load Transfer in SiC/Al Metal-Matrix Composites, J. Mater. Res., 2003, 18, p 2851–2858

R.J. Arsenault and N. Shi, Dislocation Generation due to Differences Between the Coefficients of Thermal Expansion, Mater. Sci. Eng., 1986, 81, p 175–178

Z. Zhang and D.L. Chen, Consideration of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites: A Model for Predicting Their Yield Strength, Scr. Mater., 2006, 54, p 1321–1326

C.F. Deng, X.X. Zhang, D.Z. Wang, and Y.X. Ma, Calorimetric Study of Carbon Nanotubes and Aluminum, Mater. Lett., 2007, 61, p 3221–3223

S.R. Bakshi, R.R. Patel, and A. Agarwal, Thermal Conductivity of Carbon Nanotube Reinforced Aluminum Composites: A Multi-scale Study Using Object Oriented Finite Element Method, Comput. Mater. Sci., 2010, 50, p 419–428

E.G. Colgan, M. Mäenpää, M. Finetti, and M.A. Nicolet, Electrical Characteristics of Thin Ni2Si, NiSi, and NiSi2 Layers Grown on Silicon, J. Electron. Mater., 1983, 12, p 413–422

J. Foggiato, W.S. Yoo, M. Ouaknine, T. Murakami, and T. Fukada, Optimizing the Formation of Nickel Silicide, Mater. Sci. Eng. B, 2004, 114, p 56–60

F.F. Zhao, J.Z. Zheng, Z.X. Shen, T. Osipowicz, W.Z. Gao, and L.H. Chan, Thermal Stability Study of NiSi and NiSi2 Thin Films. Microelectron, Microelectron. Eng., 2004, 71, p 104–111

D.C. Dunand, NiAl Formation by Annealing of Infiltrated Aluminium-Nickel Precursors, J. Mater. Sci., 1994, 29, p 4056–4060

H. Okamoto, Al-Ni (Aluminum-Nickel), J Phase Equilib, 1993, 14, p 257–259

Qian, J. Li, J. Xiong, F. Zhang, and X. Lin, In Situ Synthesizing Al3Ni for Fabrication of Intermetallic-Reinforced Aluminum Alloy Composites by Friction Stir Processing, Mater. Sci. Eng. A, 2012, 550, p 279–285

Acknowledgments

This work was supported by the Portuguese Foundation of Science and Technology through the project references PTDC/EME-PME/68664/2006 and EXCL/EMS-TEC/0460/2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Carvalho, O., Buciumeanu, M., Soares, D. et al. Evaluation of CNT Dispersion Methodology Effect on Mechanical Properties of an AlSi Composite. J. of Materi Eng and Perform 24, 2535–2545 (2015). https://doi.org/10.1007/s11665-015-1510-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1510-5