Abstract

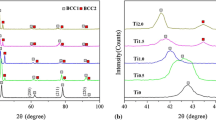

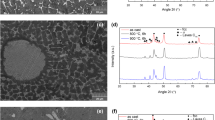

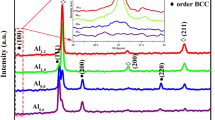

A FeCrCuMnNi high-entropy alloy was produced using vacuum induction melting, starting from high-purity raw materials. The microstructure and mechanical properties of the as-cast FeCrCuMnNi alloy were studied, considering x-ray diffraction (XRD), scanning electron microscopy, and hardness and tensile tests. XRD results revealed the existence of two FCC phases and one BCC phase. Microstructural evaluation illustrated that the as-cast alloy has a typical cast dendritic structure, where dendrite regions (BCC) were enriched in Cr and Fe. Interdendritic regions were saturated with Cu and Ni and revealed G/B(T) {110} 〈111〉 and Brass {110} 〈112〉 as the major texture components. The produced alloy revealed an excellent compromise in mechanical properties due to the mixture of solid solution phases with different structures: 300 HV hardness, 950 MPa ultimate tensile strength and 14% elongation. Microhardness test results also revealed that the BCC phase was the hardest phase. The fracture surface evidenced a typical ductile failure. Furthermore, heat treatment results revealed that phase composition remained stable after annealing up to 650 °C. Phase transformation occurred at higher temperatures in order to form more stable phases; therefore, FCC2 phase grew at the expense of the BCC phase.

Similar content being viewed by others

References

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater Sci., 2014, 61, p 1–93

C. Li, Y. Xue, M. Hua, T. Cao, L. Ma, and L. Wang, Microstructure and Mechanical Properties of AlxSi0.2CrFeCoNiCu1−x High-Entropy Alloys, Mater. Des., 2016, 90, p 601–609

S. Zhao, Y. Shao, X. Liu, N. Chen, H. Ding, and K. Yao, Pseudo-Quinary Ti20Zr20Hf20Be20 (Cu20−x Nix) High Entropy Bulk Metallic Glasses with Large Glass Forming Ability, Mater. Des., 2015, 87, p 625–631

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303

T.S. Reddy, I.S. Wani, T. Bhattacharjee, S.R. Reddy, R. Saha, and P.P. Bhattacharjee, Severe Plastic Deformation Driven Nanostructure and Phase Evolution in a Al0.5CoCrFeMnNi Dual Phase High Entropy Alloy, Intermetallics, 2017, 91, p 150–157

D.G. Shaysultanov, G.A. Salishchev, Y.V. Ivanisenko, S.V. Zherebtsov, M.A. Tikhonovsky, and N.D. Stepanov, Novel Fe36Mn21Cr18Ni15Al10 High Entropy Alloy with bcc/B2 Dual-Phase Structure, J. Alloys Compd., 2017, 705, p 756–763

Z. Li and D. Raabe, Influence of Compositional Inhomogeneity on Mechanical Behavior of an Interstitial Dual-Phase High-Entropy Alloy, Mater. Chem. Phys., 2017, 210, p 29–36

A. Shabani, M.R. Toroghinejad, A. Shafyei, and P. Cavaliere, Effect of Cold-Rolling on Microstructure, Texture and Mechanical Properties of an Equiatomic FeCrCuMnNi High Entropy Alloy, Materialia, 2018, 1, p 175–184

A. Shabani, M.R. Toroghinejad, A. Shafyei, and R.E. Logé, Evaluation of the Mechanical Properties of the Heat Treated FeCrCuMnNi High Entropy Alloy, Mater. Chem. Phys., 2019, 221, p 68–77

Y. Wu, Y. Cai, T. Wang, J. Si, J. Zhu, Y. Wang, and X. Hui, A Refractory Hf25Nb25Ti25Zr25 High-Entropy Alloy with Excellent Structural Stability and Tensile Properties, Mater. Lett., 2014, 130, p 277–280

T.-T. Shun and Y.-C. Du, Microstructure and Tensile Behaviors of FCC Al0.3CoCrFeNi High Entropy Alloy, J. Alloys Compd., 2009, 479(1), p 157–160

J. He, W. Liu, H. Wang, Y. Wu, X. Liu, T. Nieh, and Z. Lu, Effects of Al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System, Acta Mater., 2014, 62, p 105–113

A. Kuznetsov, D. Shaysultanov, N. Stepanov, G. Salishchev, and O. Senkov, Tensile Properties of an AlCrCuNiFeCo High-Entropy Alloy in As-Cast and Wrought Conditions, Mater. Sci. Eng. A, 2012, 533, p 107–118

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, and Z. Cao, A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys, Sci. Rep., 2014, 4, p 6200

B. Ren, Z. Liu, D. Li, L. Shi, B. Cai, and M. Wang, Effect of Elemental Interaction on Microstructure of CuCrFeNiMn High Entropy Alloy System, J. Alloys Compd., 2010, 493(1), p 148–153

C. Li, J. Li, M. Zhao, and Q. Jiang, Effect of Alloying Elements on Microstructure and Properties of Multiprincipal Elements High-Entropy Alloys, J. Alloys Compd., 2009, 475(1), p 752–757

B. Ren, Z. Liu, B. Cai, M. Wang, and L. Shi, Aging Behavior of a CuCr2Fe2NiMn High-Entropy Alloy, Mater. Des., 2012, 33, p 121–126

B. Murty, J.-W. Yeh, and S. Ranganathan, High-Entropy Alloys, Butterworth-Heinemann, London, 2014

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-Component Alloys, Mater. Chem. Phys., 2012, 132(2), p 233–238

A. Takeuchi and A. Inoue, Calculations of Mixing Enthalpy and Mismatch Entropy for Ternary Amorphous Alloys, Mater. Trans. JIM, 2000, 41(11), p 1372–1378

K. Zhang and Z. Fu, Effects of Annealing Treatment on Phase Composition and Microstructure of CoCrFeNiTiAlx High-Entropy Alloys, Intermetallics, 2012, 22, p 24–32

O. Senkov and D. Miracle, A New Thermodynamic Parameter to Predict Formation of Solid Solution or Intermetallic Phases in High Entropy Alloys, J. Alloys Compd., 2016, 658, p 603–607

U. Hsu, U. Hung, J. Yeh, S. Chen, Y. Huang, and C. Yang, Alloying Behavior of Iron, Gold and Silver in AlCoCrCuNi-Based Equimolar High-Entropy Alloys, Mater. Sci. Eng. A, 2007, 460, p 403–408

N. Nayan, G. Singh, S. Murty, A.K. Jha, B. Pant, K.M. George, and U. Ramamurty, Hot Deformation Behaviour and Microstructure Control in AlCrCuNiFeCo High Entropy Alloy, Intermetallics, 2014, 55, p 145–153

Y. Zhuang, H. Xue, Z. Chen, Z. Hu, and J. He, Effect of Annealing Treatment on Microstructures and Mechanical Properties of FeCoNiCuAl High Entropy Alloys, Mater. Sci. Eng. A, 2013, 572, p 30–35

G.D. Sathiaraj, P.P. Bhattacharjee, C.-W. Tsai, and J.-W. Yeh, Effect of Heavy Cryo-Rolling on the Evolution of Microstructure and Texture During Annealing of Equiatomic CoCrFeMnNi High Entropy Alloy, Intermetallics, 2016, 69, p 1–9

P. Bhattacharjee, G. Sathiaraj, M. Zaid, J. Gatti, C. Lee, C.-W. Tsai, and J.-W. Yeh, Microstructure and Texture Evolution During Annealing of Equiatomic CoCrFeMnNi High-Entropy Alloy, J. Alloys Compd., 2014, 587, p 544–552

G.D. Sathiaraj and P.P. Bhattacharjee, Analysis of Microstructure and Microtexture During Grain Growth in Low Stacking Fault Energy Equiatomic CoCrFeMnNi High Entropy and Ni–60 wt.% Co Alloys, J. Alloys Compd., 2015, 637, p 267–276

I.S. Wani, T. Bhattacharjee, S. Sheikh, I.T. Clark, M.H. Park, T. Okawa, S. Guo, P.P. Bhattacharjee, and N. Tsuji, Cold-Rolling and Recrystallization Textures of a Nano-Lamellar AlCoCrFeNi2.1 Eutectic High Entropy Alloy, Intermetallics, 2017, 84(Supplement C), p 42–51

L. Liu, J. Zhu, C. Zhang, J. Li, and Q. Jiang, Microstructure and the Properties of FeCoCuNiSnx High Entropy Alloys, Mater. Sci. Eng. A, 2012, 548, p 64–68

L. Liu, J. Zhu, L. Li, J. Li, and Q. Jiang, Microstructure and Tensile Properties of FeMnNiCuCoSnx High Entropy Alloys, Mater. Des., 2013, 44, p 223–227

Y. Zhang and W. Jie Peng, Microstructural Control and Properties Optimization of High-Entrop Alloys, Proc. Eng., 2012, 27, p 1169–1178

J.H. Hollomon, Tensile Deformation, AIME Trans., 1945, 12(4), p 1–22

Y.I. Son, Y.K. Lee, K.-T. Park, C.S. Lee, and D.H. Shin, Ultrafine Grained Ferrite–Martensite Dual Phase Steels Fabricated Via Equal Channel Angular Pressing: Microstructure and Tensile Properties, Acta Mater., 2005, 53(11), p 3125–3134

N. Saeidi, M. Karimi, and M. Toroghinejad, Development of a New Dual Phase Steel with Laminated Microstructural Morphology, Mater. Chem. Phys., 2017, 192, p 1–7

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier, Amsterdam, 2004

P. Cavaliere, B. Sadeghi, and A. Shabani, Carbon Nanotube Reinforced Aluminum Matrix Composites Produced by Spark Plasma Sintering, J. Mater. Sci., 2017, 52(14), p 8618–8629

A. Shabani and M.R. Toroghinejad, Investigation of the Microstructure and the Mechanical Properties of Cu-NiC Composite Produced by Accumulative Roll Bonding and Coating Processes, J. Mater. Eng. Perform., 2015, 24(12), p 4746–4754

A. Shabani and M.R. Toroghinejad, Study on Texture Evolution and Shear Behavior of an Al/Ni/Cu Composite, J. Mater. Eng. Perform., 2018, 27(11), p 6004–6015

S.T. Chen, W.Y. Tang, Y.F. Kuo, S.Y. Chen, C.H. Tsau, T.T. Shun, and J.W. Yeh, Microstructure and Properties of Age-Hardenable AlxCrFe 1.5 MnNi 0.5 Alloys, Mater. Sci. Eng. A, 2010, 527(21), p 5818–5825

L. Tsao, C. Chen, and C. Chu, Age Hardening Reaction of the Al0.3CrFe1.5MnNi0.5 High Entropy Alloy, Mater. Des., 2012, 36, p 854–858

R.E. Reed-Hill and R. Abbaschian, Physical Metallurgy Principles, Brooks/Cole Engineering Division Monterey, Monterey, 1973

K. Zhang, Z. Fu, J. Zhang, J. Shi, W. Wang, H. Wang, Y. Wang, and Q. Zhang, Annealing on the Structure and Properties Evolution of the CoCrFeNiCuAl High-Entropy Alloy, J. Alloys Compd., 2010, 502(2), p 295–299

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shabani, A., Toroghinejad, M.R., Shafyei, A. et al. Microstructure and Mechanical Properties of a Multiphase FeCrCuMnNi High-Entropy Alloy. J. of Materi Eng and Perform 28, 2388–2398 (2019). https://doi.org/10.1007/s11665-019-04003-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04003-4