Abstract

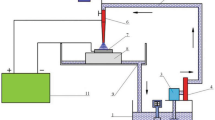

Electroplating Nickel-Molybdenum (Ni-Mo) coatings with superior corrosion and wear resistance has remained a challenge in materials sciences and engineering. Cracks caused by excessive Mo content and hydrogen evolution reaction during electroplated process are still abounded, resulting in properties degradation. Here, we develop a facile approach to produce crack-free Ni-Mo coatings with excellent properties by using ultrasound-assisted pulse electrodeposition. Effect of current density on microstructure, chemical composition, microhardness, corrosion and wear resistance of Ni-Mo coatings is systematically investigated. With the increase in current density, Mo content increases, grain size decreases and Ni-Mo coatings change from colony-like to cauliflower type morphology. The higher Mo content and smaller gain size enhance the microhardness and endow Ni-Mo coatings with superior corrosion resistance for electrochemical tests in 0.5 M H2SO4 solution. The higher microhardness improves the wear resistance of Ni-Mo coatings in tribological tests sliding against GCr15 steel ball under dry sliding condition.

Graphic Abstract

Similar content being viewed by others

References

O. Yilmaz, M. Erdogan and I. Karakaya, Combined Effects of ALS and SLS on Al2O3 Reinforced Composite Nickel Coatings, Surf. Eng., 2020, 36(5), p 477–484.

I.D. Utu, R. Muntean and I. Mitelea, Corrosion and Wear Properties of Zn-Based Composite Coatings, J. Mater. Eng. Perform., 2020, 29(8), p 5360–5365.

T. Moskalewicz, S. Zimowski, A. Fiołek, A. Łukaszczyk, B. Dubiel and Ł Cieniek, The Effect of the Polymer Structure in Composite Alumina/Polyetheretherketone Coatings on Corrosion Resistance, Micro-mechanical and Tribological Properties of the Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2020, 29(3), p 1426–1438.

S. Wan, C.H. Miao, R.M. Wang, Z.F. Zhang and Z.H. Dong, Enhanced Corrosion Resistance of Copper by Synergetic Effects of Silica and BTA Codoped in Polypyrrole Film, Prog. Org. Coat., 2019, 129, p 187–198.

H. Liu, B. Fan, G. Fan, Y. Ma, H. Hao and W. Zhang, Anti-corrosive Mechanism of poly (N-ethylaniline)/Sodium Silicate Electrochemical Composites for Copper: Correlated Experimental and In-Silico Studies, J. Mater. Sci. Technol., 2021, 72, p 202–216.

X. Wang, C.C. Chou, Y.C. Yang, R. Wu, J.W. Lee and H.Y. Chang, Tribological and Mechanical Properties of Cu/Ni-Microdiamond Bilayers on Brass Substrates Coated by Composite Electrodeposition Technology, Surf. Topogr. Metrol., 2020, 8(2), p 1–14.

X. Wang, C.C. Chou, J.W. Lee, R. Wu, H.Y. Chang and Y. Ding, Preparation and Investigation of Diamond-Incorporated Copper Coatings on a Brass Substrate by Composite Electrodeposition, Surf. Coat. Tech., 2020, 386, p 1–9.

M. Klekotka, K. Zielińska, A. Stankiewicz and M. Kuciej, Tribological and Anticorrosion Performance of Electroplated Zinc Based Nanocomposite Coatings, Coatings, 2020, 10(6), p 1–8.

P. Bera, M.D. Kumar, C. Anandan and C. Shivakumara, Characterization and Microhardness of Electrodeposited Ni-W Coatings Obtained from Gluconate Bath, Surf. Rev. Lett., 2015, 22(01), p 1–15.

R. Mousavi, M.E. Bahrololoom and F. Deflorian, The Effect of Surfactant on the Microstructure and Corrosion Resistance of Electrodeposited Ni-Mo Alloy Coatings, Anti-Corros. Method. M., 2019, 66(5), p 631–637.

S.M. Jesmani, R. Amini, H. Abdollah-Pour and H. Mohammadian-Semnani, Effect of Current Density on Ni-Mo Electrodeposition Using EMIM [Br], Surf. Eng., 2019, 35(12), p 1088–1096.

E. Chassaing, N. Portail, A.F. Levy and G. Wang, Characterisation of Electrodeposited Nanocrystalline Ni-Mo Alloys, J. Appl. Electrochem., 2004, 34(11), p 1085–1091.

R. Mousavi, K. Raeissi and A. Saatchi, The Effect of pH on the Properties of Ni-Mo Nanocrystalline Electrodeposits, Int. J. Mod. Phys B., 2008, 22(18), p 3060–3068.

J. Halim, R. Abdel-Karim, S. El-Raghy, M. Nabil and A. Waheed, Electrodeposition and Characterization of Nanocrystalline Ni-Mo Catalysts for Hydrogen Production, J. Nanomater., 2012, 2012, p 1–9.

S.I. Ghazanlou, A. Farhood, S. Ahmadiyeh, E. Ziyaei, A. Rasooli and S. Hosseinpour, Characterization of Pulse and Direct Current Methods for Electrodeposition of Ni-Co Composite Coatings Reinforced with Nano and Micro ZnO Particles, Metall. Mater. Trans A., 2019, 50(4), p 1922–1935.

S. Imanian Ghazanlou, A.H.S. Farhood, S. Hosouli, S. Ahmadiyeh and A. Rasooli, Pulse and Direct Electrodeposition of Ni-Co/Micro and Nanosized SiO2 Particles, Mater. Manuf. Process., 2018, 33(10), p 1067–1079.

S. Ahmadiyeh, A. Rasooli and M.G. Hosseini, Ni-B/SiC Nanocomposite Coating Obtained by Pulse Plating and Evaluation of Its Electrochemistry and Mechanical Properties, Surf. Eng., 2019, 35(10), p 861–872.

S.K. Singh, S. Samanta, A.K. Das and R.R. Sahoo, Electrodeposited SiC-Graphene Oxide Composite in Nickel Matrix for Improved Tribological Applications, Surf. Topogr. Metrol., 2019, 7(3), p 1–15.

M. Rostamizadeh, S. Gharibian and S. Rahimi, Ultrasound Assisted Electro-Fenton Process Including Fe-ZSM-5 Nanocatalyst for Degradation of Phenazopyridine, J. Water. Environ Nanotechnol., 2019, 4(3), p 227–235.

N.P. Wasekar, S. Verulkar, M. Vamsi and G. Sundararajan, Influence of Molybdenum on the Mechanical Properties, Electrochemical Corrosion and Wear Behavior of Electrodeposited Ni-Mo Alloy, Surf. Coat. Tech., 2019, 370, p 298–310.

C. Nee, W. Kim and R. Weil, Pulsed Electrodeposition of Ni-Mo Alloys, J. Electrochem. Soc., 1998, 135(5), p 1100–1103.

F. Xia, Q. Li, C. Ma, D. Zhao and Z. Ma, Design and Properties of Ni-TiN/SiC Nanocoatings Prepared by Pulse Current Electrodeposition, Int. J. Electrochem. Sci., 2020, 15, p 1813–1829.

C. Bai, L. An, J. Zhang, X. Zhang, B. Zhang, L. Qiang, Y. Yu and J. Zhang, Superlow Friction of Amorphous Diamond-Like Carbon Films in Humid Ambient Enabled by Hexagonal Boron Nitride Nanosheet Wrapped Carbon Nanoparticles, Chem. Eng. J., 2020, 402, p 1–12.

W. Chen, Y. Yu, J. Ma, S. Zhu, W. Liu and J. Yang, Low-Pressure Cold Spraying of Copper–Graphite Solid Lubricating Coatings on Aluminum Alloy 7075-T651, J. Therm. Spray. Techn., 2019, 28(7), p 1688–1698.

H. Lu, M.A.S. Khaing, J. Liu and L. Zou, Research on the Effect on Material Characteristics of GCr15 Steel Guide Rail in Laser Heat Treatment Condition, Adv. Mater. Res., 2012, 569, p 74–77.

A. El-Sherik, U. Erb and J. Page, Microstructural Evolution in Pulse Plated Nickel Electrodeposits, Surf. Coat. Tech., 1997, 88(1–3), p 70–78.

V.F. Lins, E.S. Cecconello and T. Matencio, Effect of the Current Density on Morphology, Porosity, and Tribological Properties of Electrodeposited Nickel on Copper, J. Mater. Eng. Perform., 2008, 17(5), p 741–745.

R. Casselton and W. Hume-Rothery, The Equilibrium Diagram of the System Molybdenum-Nickel, J. Less. Common. Met., 1964, 7(3), p 212–221.

J. Du, X. Sun, Z. Tang, L. Xu, R. Wu and B. Chen, Preparation and Microstructure of Nanocrystalline Ni-Mo Films, J. Nanosci. Nanotechno., 2013, 13(8), p 5844–5848.

D. Ernst and M. Holt, Cathode Potentials During the Electrodeposition of Molybdenum Alloys from Aqueous Solutions, J. Electrochem. Soc., 1958, 105(11), p 686–692.

E. Anderson and W. Hume-Rothery, The Equilibrium Diagram of the System Molybdenum-Nickel, J. Less. Common. Me., 1960, 2(1), p 19–28.

C. Barad, G. Kimmel, H. Hayun, D. Shamir, K. Hirshberg and Y. Gelbstein, Phase Stability of Nanocrystalline Grains of Rare-Earth Oxides (Sm2O3 and Eu2O3) Confined in Magnesia (MgO) Matrix, Materials, 2020, 13(9), p 1–14.

M. Saitou, Formation of Amorphous Iron Thin Films during Electrodeposition, Int. J. Electrochem. Sci., 2020, 15, p 434–441.

N. Qu, D. Zhu, K. Chan and W. Lei, Pulse Electrodeposition of Nanocrystalline Nickel Using Ultra Narrow Pulse Width and High Peak Current Density, Surf. Coat. Tech., 2003, 168(2–3), p 123–128.

S. Li, H. Chen, J. Liu, Y. Deng, X. Han, W. Hu and C. Zhong, Size-and Density-Controllable Fabrication of the Platinum Nanoparticle/ITO Electrode by Pulse Potential Electrodeposition for Ammonia Oxidation, Acs. Appl. Mater. Inter., 2017, 9(33), p 27765–27772.

R. Li, J. Zhou, J. Liu and B. Chen, Effects of Current Density on Preparation and Performance of Al/α-PbO2-CeO2-TiO2 Composites, Mater. Res. Express., 2019, 6(7), p 1–5.

A. Metsue and X. Feaugas, Elasticity of NixW1−x (x≤0.1875) Alloys from First Principles Calculations, Metall. Mater. Trans A., 2017, 48(11), p 5223–5227.

M. Alizadeh and A. Cheshmpish, Electrodeposition of Ni-Mo/Al2O3 Nano-Composite Coatings at Various Deposition Current Densities, Appl. Surf. Sci., 2019, 466, p 433–440.

L. Wang, Y. Gao, T. Xu and Q. Xue, A Comparative Study on the Tribological Behavior of Nanocrystalline Nickel and Cobalt Coatings Correlated with Grain Size and Phase Structure, Mater. Chem. Phys., 2006, 99(1), p 96–103.

Y. Mishima, S. Ochiai, N. Hamao, M. Yodogawa and T. Suzuki, Solid Solution Hardening of Nickel-Role of Transition Metal and B-Subgroup Solutes, Trans. Jpn. Inst. Met., 1986, 27(9), p 656–664.

P.C. Huang, K.H. Hou, H.H. Sheu, M.D. Ger and G.L. Wang, Wear Properties of Ni–Mo Coatings Produced by Pulse Electroforming, Surf. Coat. Tech., 2014, 258, p 639–645.

J. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988.

K.P. Shaha, Y.T. Pei, D. Martinez-Martinez and J.T.M.D. Hosson, Influence of Hardness and Roughness on the Tribological Performance of TiC/a-C Nanocomposite Coatings, Surf. Coat. Tech., 2010, 205(7), p 2624–2632.

L. Cao, Z. Qin, Y. Deng, C. Zhong, W. Hu and Z. Wu, Effect of Passive Film on Cavitation Corrosion Behavior of 316L Stainless Steel, Int. J. Electrochem. Sci., 2020, 15, p 628–638.

P.C. Huang, K.H. Hou, G.L. Wang, M.L. Chen and J.R. Wang, Corrosion Resistance of the Ni-Mo Alloy Coatings Related to Coating’s Electroplating Parameters, Int. J. Electrochem. Sci., 2015, 10, p 4972–4984.

S. Cho, J.H. An, S.H. Lee and J.G. Kim, Effect of pH on the Passive Film Characteristics of Lean Duplex Stainless Steel in Chloride-Containing Synthetic Tap Water, Int. J. Electrochem. Sci., 2020, 15, p 4406–4420.

S. Tao and D. Li, Tribological, Mechanical and Electrochemical Properties of Nanocrystalline Copper Deposits Produced by Pulse Electrodeposition, Nanotechnology, 2005, 17(1), p 65–78.

K. Aouadi, B. Tlili, C. Nouveau, A. Besnard, M. Chafra and R. Souli, Influence of Substrate Bias Voltage on Corrosion and Wear Behavior of Physical Vapor Deposition CrN Coatings, J. Mater. Eng. Perform., 2019, 28(5), p 2881–2891.

Acknowledgments

The authors are grateful to the financial support of the National Natural Science Foundation of China (51805089) and Training Programs of Innovation and Entrepreneurship for Undergraduates (202011845053).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, C., Huang, X., Xu, R. et al. Microstructure and Properties of Nanocrystalline Ni-Mo Coatings Prepared by Ultrasound-Assisted Pulse Electrodeposition. J. of Materi Eng and Perform 30, 2514–2525 (2021). https://doi.org/10.1007/s11665-021-05570-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05570-1