Abstract

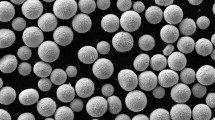

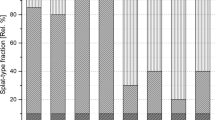

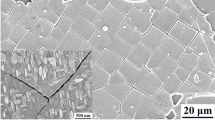

To explore the edge effect on intrasplat cracking of thermally sprayed ceramic splats, crack patterns of splats were experimentally observed and investigated through mechanical analysis. Both the polycrystalline splats and single-crystal splats showed obvious edge effects, i.e., preferential cracking orientation and differences in domain size between center fragments and edge fragments. In addition, substrate/interface delamination on the periphery was clearly observed for single-crystal splats. Mechanical analysis of edge effect was also carried out, and it was found that both singular normal stress in the substrate and huge peeling stress and shear stress at the interface were induced. Moreover, effective relief of tensile stress in splats is discussed. The good correspondence between experimental observations and mechanical analysis is elaborated. The edge effect can be used to tailor the pattern morphology and shed further light on coating structure design and optimization.

Similar content being viewed by others

References

A. Ohmori and C.J. Li, Quantitative Characterization of the Structure of Plasma-Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, 1991, 201(2), p 241-252

R. Mcpherson, A Model for the Thermal-Conductivity of Plasma-Sprayed Ceramic Coatings, Thin Solid Films, 1984, 112(1), p 89-95

S. Kuroda, T. Dendo, and S. Kitahara, Quenching Stress in Plasma-Sprayed Coatings and Its Correlation with the Deposit Microstructure, J Therm Spray Techn, 1995, 4(1), p 75-84

S. Kuroda and T.W. Clyne, The Quenching Stress in Thermally Sprayed Coatings, Thin Solid Films, 1991, 200(1), p 49-66

S. Kuroda, T. Fukushima, and S. Kitahara, Significance of Quenching Stress in the Cohesion and Adhesion of Thermally Sprayed Coatings, J Therm Spray Techn, 1992, 1(4), p 325-332

C.J. Li and A. Ohmori, Relationships Between the Microstructure and Properties of Thermally Sprayed Deposits, J Therm Spray Techn, 2002, 11(3), p 365-374

S. Rangarajan and A.H. King, Non-destructive Evaluation of Delamination in Ceramic Thin Films on Metal Substrates by Scanning Electron Microscopy, Thin Solid Films, 2001, 385(1-2), p 22-28

T. Chraska and A.H. King, Effect of Different Substrate Conditions upon Interface with Plasma Sprayed Zirconia-A TEM Study, Surf Coat Tech, 2002, 157(2-3), p 238-246

L. Chen, G.-J. Yang, C.-X. Li, and C.-J. Li, Hierarchical Formation of Intrasplat Cracks in Thermal Spray Ceramic Coatings, J Therm Spray Techn, 2016, 25(5), p 959-970

I. Dewolf, J. Vanhellemont, A. Romanorodriguez, H. Norstrom, and H.E. Maes, Micro-Raman Study of Stress-Distribution in Local Isolation Structures and Correlation with Transmission Electron-Microscopy, J. Appl. Phys., 1992, 71(2), p 898-906

A. Atkinson, T. Johnson, A. Harker, and S. Jain, Film Edge-induced Stress in Substrates and Finite Films, Thin Solid Films, 1996, 274(1), p 106-112

S. Jain, A. Harker, A. Atkinson, and K. Pinardi, Edge-induced Stress and Strain in Stripe Films and Substrates: A Two-dimensional Finite Element Calculation, J. Appl. Phys., 1995, 78(3), p 1630-1637

S.M. Hu, Film-Edge-Induced Stress in Silicon Substrates, Appl. Phys. Lett., 1978, 32(1), p 5-7

S.M. Hu, Film-Edge-Induced Stress in Substrates, J. Appl. Phys., 1979, 50(7), p 4661-4666

S.C. Jain, H.E. Maes, K. Pinardi, and I. DeWolf, Stresses and Strains in Lattice-Mismatched Stripes, Quantum Wires, Quantum Dots, and Substrates in Si Technology, J. Appl. Phys., 1996, 79(11), p 8145-8165

X.C. Zhang, B.S. Xu, H.D. Wang, and Y.X. Wu, Analytical Modeling of Edge Effects on the Residual Stresses Within the Film/substrate Systems. I. Interfacial Stresses, J. Appl. Phys., 2006, 100(11), p 113525

E. Suhir, Stresses in Bi-Metal Thermostats, J. Appl. Mech., 1986, 53(3), p 657-660

E. Suhir, Interfacial Stresses in Bimetal Thermostats, J. Appl. Mech., 1989, 56(3), p 595-600

E. Suhir, An Approximate Analysis of Stresses in Multilayered Elastic Thin Films, J. Appl. Mech., 1988, 55(1), p 143-148

H. Yin, G. Paulino, and W. Buttlar, An Explicit Elastic Solution for A Brittle Film with Periodic Cracks, Int J Fracture, 2008, 153(1), p 39-52

H. Yin, Opening-Mode Cracking in Asphalt Pavements Crack Initiation and Saturation, Road Mater Pavement, 2010, 11(2), p 435-457

Z.C. Xia and J.W. Hutchinson, Crack Patterns in Thin Films, J. Mech. Phys. Solids, 2000, 48(6-7), p 1107-1131

Z. Suo and J.W. Hutchinson, Interface Crack Between Two Elastic Layers, Int J Fracture, 1990, 43(1), p 1-18

Z. Suo and J.W. Hutchinson, Steady-state Cracking in Brittle Substrates Beneath Adherent Films, Int. J. Solids Struct., 1989, 25(11), p 1337-1353

A. Bagchi and A.G. Evans, The Mechanics and Physics of Thin Film Decohesion and Its Measurement, Interface Sci., 1996, 3(3), p 169-193

J.L. Beuth, Cracking of Thin Bonded Films in Residual Tension, Int. J. Solids Struct., 1992, 29(13), p 1657-1675

J.P. Parmigiani and M.D. Thouless, The roles of toughness and cohesive strength on crack deflection at interfaces, J. Mech. Phys. Solids, 2006, 54(2), p 266-287

J.W. Hutchinson and Z. Suo, Mixed-Mode Cracking in Layered Materials, Adv. Appl. Mech., 1992, 29, p 63-191

Acknowledgments

The present project is supported by National Basic Research Program (No. 2013CB035701), the Fundamental Research Funds for the Central Universities, and the National Program for Support of Top-notch Young Professionals.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The constitutive law in regard to thermal strain without consideration of bending problem reads

where ɛ 0 f and ɛ 0 s are the uniform strain of the splat and substrate without consideration of bending, respectively. Moreover, σ i f and σ i s are the uniform stress of the splat and substrate, respectively. Using the condition of the strain compatibility at the film/substrate interface gives

The force balance of the whole bimaterial beams dictates

Combination of Eq 28 and 29 gives

The moments due to uniform strain component, \(M^{\text{i}}\), can thus be expressed as

where δ is the location of the neutral axis composite beam. The quantity δ was calculated on the assumption of equivalent cross section (Ref 25) as shown in Fig. 10, which was defined as

where y f and y s are the location of the neutral axis of film and substrate, respectively. The quantities A f and A s are the equivalent cross-sectional area of film and substrate, as shown in Fig. 10(b), respectively. Therefore, δ can further be reduced to

To balance the moment \(M^{\text{i}}\), an extra moment \(M^{\text{b}}\) is required, which in return gives rise to stress redistribution in bimaterial beam.

The pure bending strain due to \(M^{\text{b}}\) dictates the function form

where r is the radius of curvature for neutral axis of composite beam.

The bending moment, \(M^{\text{b}}\), related to the pure bending strains \(\varepsilon^{\text{b}}\), can be expressed as

The moment balance of the whole bimaterial beam follows \(M^{\text{i}} + M^{\text{b}} = 0\), which in conjunction with Eq 31, 34, and 35 dictates

The total strain in the film (the upper beam) can thus be expressed as

In the present study,

Therefore, the strain and stress in the film can be reduced to

Rights and permissions

About this article

Cite this article

Chen, L., Yang, GJ., Li, CX. et al. Edge Effect on Crack Patterns in Thermally Sprayed Ceramic Splats. J Therm Spray Tech 26, 302–314 (2017). https://doi.org/10.1007/s11666-016-0505-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0505-6