Abstract

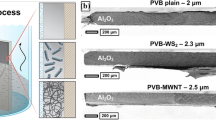

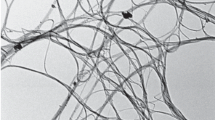

In this paper the tungsten-fibre-net-reinforced tungsten composites were produced by spark plasma sintering (SPS) using fine W powders and commercial tungsten fibres. The relative density of the samples is above 95%. It was found that the recrystallization area in the fibres became bigger with increasing sintering temperature and pressure. The tungsten grains of fibres kept stable when sintered at 1350°C/16 kN while grown up when sintered at 1800°C/16 kN. The composite sintered at 1350°C/16 kN have a Vickers-hardness of ~610 HV, about 2 times that of the 1800°C/16 kN sintered one. Tensile tests imply that the temperature at which the composites (1350°C/16 kN) begin to exhibit plastic deformation is about 200°C-250°C, which is 400°C lower than that of SPSed pure W. The tensile fracture surfaces show that the increasing fracture ductility comes from pull-out, interface debonding and fracture of fibres.

Similar content being viewed by others

References

Liu L, Liu D P, Hong Y, et al. High-flux He+ irradiation effects on surface damages of tungsten under ITER relevant conditions. Journal of Nuclear Materials, 2016, 471: 1–7

Li X W, Zhang M N, Zheng D H, et al. The oxidation behavior of the WC–10 wt.% Ni3Al composite fabricated by spark plasma sintering. Journal of Alloys and Compounds, 2015, 629: 148–154

Dai S Y,Wang L, Kirschner A, et al. Kinetic modelling of material erosion and impurity transport in edge localized modes in EAST. Nuclear Fusion, 2015, 55(4): 043003 (8 pages)

Palacios T, Monge M A, Pastor J Y. Tungsten–vanadium–yttria alloys for fusion power reactors (I): Microstructural characterization. International Journal of Refractory Metals and Hard Materials, 2016, 54: 433–438

Ekbom L B. Tungsten heavy-metals. Scandinavian Journal of Metallurgy, 1991, 20(3): 190–197

Giannattasio A, Yao Z, Tarleton E, et al. Brittle-ductile transitions in polycrystalline tungsten. Philosophical Magazine, 2010, 90(30): 3947–3959

Miao S, Xie Z M, Yang X D, et al. Effect of hot rolling and annealing on the mechanical properties and thermal conductivity of W–0.5 wt.% TaC alloys. International Journal of Refractory Metals & Hard Materials, 2016, 56: 8–17

Xie Z M, Zhang T, Liu R, et al. Grain growth behavior and mechanical properties of zirconium microalloyed and nano-size zirconium carbide dispersion strengthened tungsten alloys. International Journal of Refractory Metals & Hard Materials, 2015, 51: 180–187

Liu S L, Ye X X, Jiang L, et al. Effect of tungsten content on the microstructure and tensile properties of Ni–xW–6Cr alloys. Materials Science and Engineering A: Structural Materials Properties Microstructure and Processing, 2016, 655: 269–276

Wang S, Chen C, Jia Y L, et al. Effects of grain size on the microstructure and texture of cold-rolled Ta–2.5W alloy. International Journal of Refractory Metals & Hard Materials, 2016, 58: 125–136

Sinclair R, Preuss M, Maire E, et al. The effect of fibre fractures in the bridging zone of fatigue cracked Ti–6Al–4V/SiC fibre composites. Acta Materialia, 2004, 52(6): 1423–1438

Kimmig S, Allen I, You J H. Strength and conductivity of unidirectional copper composites reinforced by continuous SiC fibers. Journal of Nuclear Materials, 2013, 440(1–3): 272–277

Conner R D, Dandliker R B, Johnson W L. Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5-Ni10Be22.5 metallic glass matrix composites. Acta Materialia, 1998, 46(17): 6089–6102

Carvalho P A, Livramento V, Nunes D, et al. Tungsten–tantalum composites for plasma facing applications. Materials for Energy, 2010, 4–8

Pemberton S R, Oberg E K, Dean J, et al. The fracture energy of metal fibre reinforced ceramic composites (MFCs). Composites Science and Technology, 2011, 71(3): 266–275

Son C Y, Kim G S, Lee S B, et al. Dynamic compressive properties of Zr-based amorphous matrix composites reinforced with tungsten continuous fibers or porous foams. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2012, 43(6): 1911–1920

Zhang B, Fu H M, Sha P F, et al. Anisotropic compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Materials Science and Engineering A: Structural Materials Properties Microstructure and Processing, 2013, 566: 16–21

Riesch J, Buffiere J Y, Hoschen T, et al. In situ synchrotron tomography estimation of toughening effect by semi-ductile fibre reinforcement in a tungsten-fibre-reinforced tungsten composite system. Acta Materialia, 2013, 61(19): 7060–7071

Riesch J, Aumann M, Coenen J W, et al. Chemically deposited tungsten fibre-reinforced tungsten–The way to a mock-up for divertor applications. Nuclear Materials and Energy, 2016, 9: 75–83

Zhang L H, Jiang Y, Fang Q F, et al. Toughness and microstructure of tungsten fibre net-reinforced tungsten composite produced by spark plasma sintering. Materials Science and Engineering A: Structural Materials Properties Microstructure and Processing, 2016, 659: 29–36

Du J, Höschen T, Rasinski M, et al. Interfacial fracture behavior of tungsten wire/tungsten matrix composites with copper-coated interfaces. Materials Science and Engineering A: Structural Materials Properties Microstructure and Processing, 2010, 527(6): 1623–1629

Du J, Höschen T, Rasinski M, et al. Feasibility study of a tungsten wire-reinforced tungsten matrix composite with ZrOx interfacial coatings. Composites Science and Technology, 2010, 70(10): 1482–1489

Du J, Höschen T, Rasinski M, et al. Shear debonding behavior of a carbon-coated interface in a tungsten fiber-reinforced tungsten matrix composite. Journal of Nuclear Materials, 2011, 417(1–3): 472–476

Xie Z M, Liu R, Fang Q F, et al. Spark plasma sintering and mechanical properties of zirconium micro-alloyed tungsten. Journal of Nuclear Materials, 2014, 444(1–3): 175–180

Asrar N, Meshkov L L, Sokolovskaya E M. Interdiffusional effects in tungsten fiber reinforced nickel-matrix composites. Transactions of the Indian Institute of Metals, 1990, 43(6): 364–367

Lee M H, Das J, Sordelet D J, et al. Effect of tungsten metal particle sizes on the solubility of molten alloy melt: Experimental observation of Gibbs-Thomson effect in nanocomposites. Applied Physics Letters, 2012, 101(12): 124103

Acknowledgements

This work was supported by the National Magnetic Confinement Fusion Program (Grant No. 2015GB112000), the National Natural Science Foundation of China (Grant Nos. 51301164, 11274305 and 11475216), and the Anhui Provincial Natural Science Foundation of China (1408085QE77).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Jiang, Y., Fang, Q. et al. Microstructure and mechanical properties of tungsten composite reinforced by fibre network. Front. Mater. Sci. 11, 190–196 (2017). https://doi.org/10.1007/s11706-017-0378-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-017-0378-8