Abstract

Grinding and honing processes are quality-defining operations in the production of many modern products. Process performance and product quality are contingent on selecting the correct abrasive tool for a specific application. Thus, tools with different bonding systems are used, namely resin bonded tools, vitrified bonded tools, and metallic bonded tools. Tool manufacturers have great knowledge in the choice and intricate production of these bond types and their countless variants. Most bond systems pass through mixing, forming, pressing, heat treatment, and post-processing steps. Single-layer metallic bonds can be generated by electroplating or brazing processes. This article reviews the manufacturing of tools with different bonding systems and discusses their ingredients. Furthermore, the economic, environmental and social dimension of tool production and tool use are considered to understand sustainability issues of different bond types. The review of tool manufacturing is necessary to enable informed life cycle assessments or other sustainability analyses for grinding or honing.

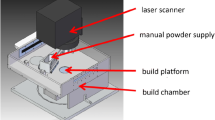

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Reproduced with permission from [57]

Similar content being viewed by others

References

Aurich JC, Linke B, Hauschild M, Carrella M, Kirsch B (2013) Sustainability of abrasive processes. CIRP Ann Manuf Technol 62(2):653–672. doi:10.1016/j.cirp.2013.05.010

Winter M, Ibbotson S, Kara S, Herrmann C (2015) Life cycle assessment of cubic boron nitride grinding wheels. J Clean Prod 107:707–721. doi:10.1016/j.jclepro.2015.05.088

Kirsch B, Effgen C, Büchel M, Aurich JC (2014) Comparison of the embodied energy of a grinding wheel and an end mill. Proc CIRP 15:74–79. doi:10.1016/j.procir.2014.06.037

Linke BS (2014) Sustainability concerns in the life cycle of bonded grinding tools. CIRP J Manuf Sci Technol 7(3):258–263. doi:10.1016/j.cirpj.2014.05.002

Marinescu ID, Rowe WB, Dimitrov B, Inasaki I (2004) Tribology of abrasive machining processes. William Andrew Inc., New York

Klocke F (2009) Manufacturing processes 2—grinding, honing, lapping (trans: Kuchle A). Springer, Berlin, Heidelberg. ISBN 978-3-540-92258-2

Stockwell BH (1986) Die Metallurgie der Metallwerkzeuge. Ind Diam Rundsch 1(86):31–35

Tyrolit. Wie entsteht ein Tyrolit Schleifwerkzeug, Anhang 1, Anhang 2 (Z1), 2nd edn. Company brochure, Dec 2003

Colleselli K, Schwieger KH (1988) Schleifscheiben und Schleifkörper. In: Becker/Braun (ed) Kunststoff-Handbuch 10—Duroplaste. Hanser Verlag, Munich, pp 894–908. ISBN 978-3-446-14418-7

Gardziella A, Pilato L, Knop A (2000) Phenolic resins: chemistry, applications, standardization, safety, and ecology, 2nd edn. Springer, New York

NN (2006) Schleifwerkzeuge KAD-100/2006. Company brochure. Krebs & Riedel Schleifscheibenfabrik

Klocke F, König W (2005) Fertigungsverfahren Band 2—Schleifen, Honen, Läppen. 4.Auflage edn. Springer

Marinescu ID, Hitchiner M, Uhlmann E, Rowe WB, Inasaki I (2007) Handbook of machining with grinding wheels. CRC Press, Boca Raton

Rowe WB (2009) Principles of modern grinding technology. William Andrew Inc., New York

Menard J-C, Thibault NW (2000) Abrasives. In: Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH Verlag GmbH & Co. KGaA. doi:10.1002/14356007.a01_001

Asami M, Santorelli M (2010) Abrasives, Chapter 13. In: Pilato L (ed) Phenolic resins: a century of progress. Springer, New York, pp 307–343

Metzger JL (1986) Superabrasive grinding. Butterworth & Co., London

Harper CA, Petrie EM (2003) Plastics materials and processes: a concise encyclopedia. Wiley, Hoboken

Harris DI (1983) Patent US 4,404,003—microwave heating process for grinding wheels, 13 Sept 1983

Francois EC, Zhang G, Klett MW (2010) Patent application publication US 2010/0190424 A1. Reinforced bonded abrasive tools

Hickory GE, White MJ (1991) Patent US 5,061,295—Grinding wheel abrasive composition

Herbert S (1980) Norton ‘re-invents’ the resinoid wheel. Ind Diam Rev 281–283

NN (1974) Patent GB1344681. Resin bonded abrasive products

Stuckenholz B (1988) Das Abrichten von CBN-Schleifscheiben mit kleinen Zustellungen. RWTH Aachen University

Beyer P (2004) Hochproduktives Schleifen mit keramisch gebundenen Superabrasives Teil 1: die HPB-Technologie für Vit-CBN-Schleifwerkzeuge. Industrie Diamanten Rundschau 4:344 ff

Hadert H (1966) Aufbau von Schleifscheiben und Schleifpapieren. Chem Ztg Chem Appar 90(23):801

Padberg H-J (1993) Aufbau und Bindungsmatrix hochbeanspruchter keramisch gebundener Zerspanungswerkzeuge. Ind Forum cfi Ber Dtsch Keram Ges 70(11/12):598–600

Jackson MJ, Davim JP (2011) Machining with abrasives. Springer. doi:10.1007/978-1-4419-7302-3

Tyrolit (2003) Grindology boxes, Begleitheft zum Koffer „Allgemeine Grundlagen 1“, Accompanying notes to case “General Basics 1”, 2nd edn. Tyrolit

Jackson MJ (1995) A study of vitreous-bonded abrasive materials. PhD thesis, Liverpool John Moores University, UK

Helletsberger H, Sigwart K, Neururer K, Noichl H (1994) CBN-Schleifscheiben in Keramik; Eine neue Ära hat begonnen; Folge 1. Schleif Trenn Tyrolit 120:13–20

Bot-Schulz R (2005) Untersuchung der Reaktionen an der Schnittstelle Korn/Bindung für Sol-Gel-Korund. Doctoral thesis, RWTH Aachen University

Messer P (1991) Batching and mixing. In: Schneider SJ Jr et al (eds) Engineered materials handbook: ceramics and glasses. ASM International, Almere, pp 95–99

Huzinec GM (2000) Patent US 6123744. Vitreous bond compositions for abrasive articles

Behrens B-A, Seidel H-J, Kammler M (2011) Vergleichende experimentelle und numerische Untersuchungen zum schwingungsüberlagerten Pressen zweier Pulvermaterialien. Mat-wiss u Werkstofftech 42:705–711. doi:10.1002/mawe.201100757

Malkin S, Guo C (2008) Grinding technology: theory and application of machining with abrasives, 2nd edn. Industrial Press, New York

Moser M (1980) Microstructures of ceramics: structure and properties of grinding tools. Akadémiai Kiadó, Budapest

Huzinec GM, Koval WF (2012) Patent US 8206473. Abrasive composition and article forme therefrom

Jackson MJ (2007) Sintering and vitrification heat treatment of cBN grinding wheels. J Mater Process Technol 191(1–3):232–234

Rammerstorfer FG, Hastik F (1974) Der dynamische E-Modul von Schleifkörpern. Werkstatt Betr 107(9):527–533

Hay J, Markhoff-Matheny CJ, Swanson BE. Patent US 4,898,597. Frit bonded abrasive wheel. Norton Company, 6 Feb 1990

Davis TD, DiCorletob J, Sheldon D, Vecchiarelli J, Erkey C (2004) A route to highly porous grinding wheels by selective extraction of pore inducers with dense carbon dioxide. J Supercrit Fluids 30(3):349–358

NN (2012) GESTIS-Stoffdatenbank. Institut fuer Arbeitsschutz der Deutschen Gesetzlichen Unfallversicherung

Yarnitsky Y, Dolev D (1969) Porosity—the third phase in grinding wheels. IDR 29(347): 414 f

Wegener K, Hoffmeister H-W, Karpuschewski B, Kuster F, Hahmann W-C, Rabiey M (2011) Conditioning and monitoring of grinding wheels. Ann CIRP 60(2):757–777

Klaus J (1976) Der Einsatz von Grafit bei der Herstellung von Diamantwerkzeugen. Ind Diam Rundsch 10(4):223–228

Young B (1966) The graphitisation of diamond during the manufacture of diamond tools. Ind Diamond Rev 26(312):483–488

Fritsch (2005) Hot stuff! New sintering press makes high temperatures quick and easy. Metal-powder.net. http://www.dr-fritsch.de/tl_files/aktuelles/publikationen/06_mpr_5_2005_hochsinter.pdf. Accessed 1 Dec 2012

Klocke F, König W (2007) Fertigungsverfahren Band 3—Abtragen, Generieren, Lasermaterialbearbeitung. 4. Auflage edn. Springer, Berlin, Heidelberg. ISBN 978-3-540-48954-2

Bold L (2002) Galvanische Werkzeuge—Ein Leitfaden. Saint-Gobain Abrasives, company brochure

Kraft I, Mertens U Trends in der Schleifscheibenentwicklung bei Diamant- und CBN-Werkzeugen. In: 3. Dortmunder Schleifseminar, Dortmund, Germany, 25 Sept 2008

Chattopadhyay AK, Chollet L, Hintermann HE (1990) On performance of chemically bonded single-layer CBN grinding wheel. Ann CIRP 39(1):309–312

Ding WF, Xu JH, Fu YC, Xiao B, Su HH, Xu HJ (2006) Interfacial reaction between cubic boron nitride and Ti during active brazing. J Mater Eng Perform 15(3):365–369

Upadhyay RD, Ramanath S, Corcoran Jr RF, Puthanangady T, Hall RWJ, Harley LL. Patent WO2009075775. Multifunction abrasive tool with hybrid bond

Chalkley JR, Thomas DM (1972) Patent GB1279413. Improvements in abrasive wheels and other tools

(EPA) UEPA (1994) Emission factor documentation for AP-42, Section 11.31, Abrasives Manufacturing, Final Report. Midwest Research Institute (MRI)

Linke B (2016) Bonding systems. In: Life cycle and sustainability of abrasive tools, chap 3. Springer, Switzerland

Acknowledgments

The author would like to thank the DFG for the support and Ian Garretson, UC Davis for reviewing the article. Part of this work was sponsored by the Deutsche Forschungsgemeinschaft (DFG) through the Project LI1939/3-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an abbreviated version of Springer book “Life Cycle and Sustainability of Abrasive Tools”, Chapter 3 “Bonding Systems”, pages 63–95, authored by B. Linke, published by Springer in 2016, with copyright permission of Springer.

Rights and permissions

About this article

Cite this article

Linke, B. Manufacturing and sustainability of bonding systems for grinding tools. Prod. Eng. Res. Devel. 10, 265–276 (2016). https://doi.org/10.1007/s11740-016-0668-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-016-0668-5