Abstract

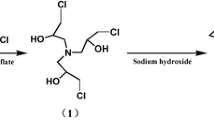

The most commonly used curing agents for soy-based adhesives are polyamines, which have the problem of low solid content and/or high viscosity. To overcome this problem, a new type of polyamidoamine (PADA) resin was synthesized and applied to soy flour-based adhesives to improve their water resistance. The PADA solution obtained had a high solid content of 50 wt% and low viscosity of 270 cP. The optimum weight ratio of soy flour/PADA/maleic anhydride to prepare adhesive was 40/7/1.68. The wet strength of plywood prepared at the optimum weight ratio was 0.82 MPa, which meant the plywood could be used as type II plywood according to the Chinese National Standard GB/T 9846.7-2004. The results of water-insoluble solid content measurement and SEM observation demonstrated that cured soy flour–PADA–maleic anhydride adhesive had a 16 % greater water-insoluble solid content than soy flour–NaOH adhesive. The cross-linking network formed by the reactions of PADA and MA would increase the water-insoluble solid contents and improve water resistance of cured soy flour-based adhesives.

Similar content being viewed by others

References

He J, Zhang C, Zhang D (2012) Analysis on the development of wood-based panel industry in 2011 in Heilongjiang province. For Mach Woodwork Equip 40(6):11–13

Jang Y, Huang J, Li K (2011) A new formaldehyde-free wood adhesive from renewable materials. Int J Adhes Adhes 31(7):754–759

International Agency for Research on Cancer classifies formaldehyde as carcinogenic to humans (2004) International Agency for Research on Cancer Press release # 153

Wescott JM, Traska A, Frihart CR, Lorenz L (2006) Durable soy-based adhesive dispersions. In: Wood adhesives 2005. Forest Product Society, Madison, pp 263–270

Hettiarachchy NS, Kalapathy U, Myers DJ (1995) Alkali-modified soy protein with improved adhesive and hydrophobic properties. J Am Oil Chem Soc 72:1461–1464

Liu Y, Li K (2002) Chemical modification of soy protein for wood adhesives. Macromol Rapid Commun 23:739–742

Liu Y, Li K (2004) Modification of soy protein for wood adhesives using mussel protein as a model: the influence of a mercapto group. Macromol Rapid Commun 25:1835–1838

Huang W, Sun X (2000) Adhesive properties of soy proteins modified by sodium dodecyl sulfate and sodium dodecylbenzene sulfonate. J Am Oil Chem Soc 77:705–708

Huang W, Sun X (2000) Adhesive properties of soy proteins modified by urea and guanidine hydrochloride. J Am Oil Chem Soc 77:101–104

Li K, Svetlana P, Geng X (2004) Investigation of soy protein-Kymene® adhesive systems for wood composites. J Am Oil Chem Soc 81:487–491

Li K (2002) Formaldehyde-free lignocellulosic adhesives and composites made from the adhesives. US Patent 7,252,735

Li K, Liu Y (2006) Modified protein adhesives and lignocellulosic composites made from the adhesives. US Patent 7,060,798

Yang G, Yang B, Yuan C, Geng W, Li H (2011) Effects of preparation parameters on properties of soy protein-based fiberboard. J Poly Environ 19:146–151

http://www.soy-baby.com/, accessed on June 8, 2012

http://ozero-inside.com/. Accessed 8 June 2012

Wu D, Yu ZF, Liu XQ (2011) Study on the properties and preparation of plywood bonded with soybean-based formaldehyde-free adhesive. China For Product Ind 39(1):15–18

Huang J, Li K (2007) A new soy flour-based adhesive for making interior type II plywood. J Am Oil Chem Soc 85:63–70

Liu Y, Li K (2007) Development and characterization of adhesives from soy protein for bonding wood. Int J Adhes Adhes 27:59–67

Spraul B, Brady R, Allen A (2008) Adhesive composition of low molecular weight polyaminoamide–epichlorohydrin (PAE) resin and protein. US Patent 2008/0050602

Varnell D, Spraul B, Evans M (2011) Adhesive compositions. US Patent 2011/0190423

Zhong Z, Sun X, Wang D (2007) Isoelectric pH of polyamide–epichlorohydrin modified soy protein improved water resistance and adhesion properties. J Appl Polym Sci 103:2261–2270

Zhu H, Chen J, Tang J, Xia N, Wang Y, Wang S (2012) Preparation and optimum conditions of polyamide polyamine compounds by polycondensation. Adv Mater Res 398:2092–2097

Johnson O (1923) Adhesive. US Patent 1,406,757

Davidson G, Cone CN, Laucks I, Banks H (1934) Method of making an adhesive and the product thereof. US Patent 1,985,631

Lin Q, Chen N, Bian L, Fan M (2012) Development and mechanism characterization of high performance soy-based bio-adhesives. Int J Adhes Adhes 34:11–16

Chinese National Standard GB/T 9846.7-2004. Plywood—part 7: cutting of test specimens

Chinese National Standard GB/T 17657-1999. Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels

Frihart C (2003) Durable wood bonding with epoxy adhesives. In: Proceedings 26th annual meeting of the Adhesion Society. The Adhesion Society, Blacksburg, pp 476–478

Liu W, Ni Y, Xiao H (2004) Montmorillonite intercalated with polyaminoamide–epichlorohydrin: preparation, characterization, and sorption behavior. J Colloid Interface Sci 275:584–589

Zhong Z, Sun X, Wang D, Ratto JA (2003) Wet strength and water resistance of modified soy protein adhesives and effects of drying treatment. J Poly Environ 11:137–144

Hunt C, Lorenz L, Wescott JM (2009) Soy adhesive-moisture interactions. In: Wood adhesives 2009. Forest Product Society, Madison, pp 270–274

Acknowledgments

This project was funded by the Ningbo Polymer Innovative Research Team (Grant No. 2009B21008) and Ningbo Key Lab of Polymer Materials (Grant No. 2010A22001). The generosity of the Ningbo Zhongke Bayi New Materials Co., Ltd. is much appreciated for their providing us with poplar veneers.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Gui, C., Liu, X., Wu, D. et al. Preparation of a New Type of Polyamidoamine and Its Application for Soy Flour-Based Adhesives. J Am Oil Chem Soc 90, 265–272 (2013). https://doi.org/10.1007/s11746-012-2160-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-012-2160-5