Abstract

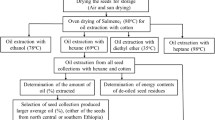

The aim of the current research was to determine a less hazardous, cheaper and less toxic alternative solvent for hexane for extraction of oil from different oilseeds showing equivalent oil yield and oil quality. A full factorial design with three levels of extraction temperature (80, 100 and 120 °C) and three levels of extraction time (40, 65 and 90 min) with constant solvent to seed ratio value of 4:1 was used to extract the oil. Maximum oil was recovered from canola followed by flax, mustard and camelina. The oil content of canola was found in range of 21.08–36.44, and 25.12–40.38 % for hexane and ethyl acetate, respectively. The heating values of oil extracted from all oilseeds using hexane and ethyl acetate were found in the range of 38.04–39.98 and 37.98–39.37 MJ/kg, respectively. Least viscosity was found for flax seed using hexane followed by camelina, canola and mustard as compared to ethyl acetate. Viscosity of flax oil ranged from 27.23–37.19, and 31.16–55.52 cP for hexane and ethyl acetate solvents, respectively. Considering human safety, less environmental impact, comparable oil yield and quality parameters, ethyl acetate can be a promising alternative to hexane.

Similar content being viewed by others

Abbreviations

- ASE:

-

Accelerated solvent extractor

- Cn:

-

Canola

- Cm:

-

Camelina

- EA:

-

Ethyl acetate

- Fx:

-

Flax

- H:

-

Hexane

- MC:

-

Moisture content

- Mt:

-

Mustard

References

Hanmoungjai P, Pyle L, Niranjan K (2000) Extraction of rice bran oil using aqueous media. J Chem Technol Biotechnol 75(5):348–352. doi:10.1002/(SICI)1097-4660(200005)75:5<348:AID-JCTB233>3.0.CO;2-P

Gandhi AP, Joshi KC, Jha K, Parihar VS, Srivastav DC, Raghunadh P, Kawalkar J, Jain SK, Tripathi RN (2003) Studies on alternative solvents for the extraction of oil-I soybean. Int J Food Sci Technol 38(3):369–375. doi:10.1046/j.1365-2621.2003.00683.x

Conkerton EJ, Wan PJ, Richard OA (1995) Hexane and heptane as extraction solvents for cottonseed: a laboratory-scale study. J Am Oil Chem Soc 72(8):963–965. doi:10.1007/BF02542075

Sineiro J, Domínguez H, Núñez MJ, Lema JM (1998) Ethanolic extraction of sunflower oil in a pulsing extractor. J Am Oil Chem Soc 75(6):753–754. doi:10.1007/s11746-998-0220-7

Seth S, Agrawal YC, Ghosh PK, Jayas DS, Singh BPN (2007) Oil extraction rates of soya bean using isopropyl alcohol as solvent. Biosyst Eng 97(2):209–217. doi:10.1016/j.biosystemseng.2007.03.008

Oliveira R, Oliveira V, Aracava KK, Rodrigues CEdC (2012) Effects of the extraction conditions on the yield and composition of rice bran oil extracted with ethanol—A response surface approach. Food Bioprod Process 90(1):22–31. doi:10.1016/j.fbp.2011.01.004

Tir R, Dutta PC, Badjah-Hadj-Ahmed AY (2012) Effect of the extraction solvent polarity on the sesame seeds oil composition. Eur J Lipid Sci Technol 114(12):1427–1438. doi:10.1002/ejlt.201200129

Matthäus B, Brühl L (2001) Comparison of different methods for the determination of the oil content in oilseeds. J Am Oil Chem Soc 78(1):95–102. doi:10.1007/s11746-001-0226-y

Oomah BD, Mazza G, Przybylski R (1996) Comparison of flaxseed meal lipids extracted with different solvents. LWT-Food Sci Technol 29(7):654–658. doi:10.1006/fstl.1996.0100

Liu SX, Mamidipally PK (2005) Quality comparison of rice bran oil extracted with d-limonene and hexane. Cereal Chem J 82(2):209–215. doi:10.1094/CC-82-0209

Virot M, Tomao V, Ginies C, Chemat F (2008) Total lipid extraction of food using d-limonene as an alternative to n-hexane. Chroma 68(3–4):311–313. doi:10.1365/s10337-008-0696-1

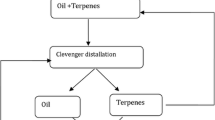

Dejoye Tanzi C, Abert Vian M, Ginies C, Elmaataoui M, Chemat F (2012) Terpenes as green solvents for extraction of oil from microalgae. Molecules 17(7):8196–8205

ISO (2009) Oilseeds-determination of oil content (Reference method). EN ISO 659:2009

AOAC (1980) Official methods of analysis. Air oven method, 13 edn. Association of official analytical chemist, Washington, DC

AOCS (2003) In: Firestone D (ed) Official methods and recommended practices of the American Oil Chemists’ Society. AOCS Press, Champaign

Giergielewicz-Możajska H, Dąbrowski Ł, Namieśnik J (2001) Accelerated solvent extraction (ASE) in the analysis of environmental solid samples—some aspects of theory and practice. Crit Rev Anal Chem 31(3):149–165. doi:10.1080/20014091076712

Latif S, Diosady LL, Anwar F (2008) Enzyme-assisted aqueous extraction of oil and protein from canola (Brassica napus L.) seeds. Eur J Lipid Sci Technol 110(10):887–892. doi:10.1002/ejlt.200700319

Thompson J, He B (2006) Characterization of crude glycerol from biodiesel production from multiple feedstocks. Appl Eng Agric 22(2):261

Giakoumis EG (2013) A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation. Renew Energy 50:858–878. doi:10.1016/j.renene.2012.07.040

Dobre P, Jurcoane S (2011) Camelina crop-opportunities for a sustainable agriculture. Sci Pap Ser A Agron 54:420–424

Bernardo A, Howard-Hildige R, O’Connell A, Nichol R, Ryan J, Rice B, Roche E, Leahy JJ (2003) Camelina oil as a fuel for diesel transport engines. Ind Crops Prod 17(3):191–197. doi:10.1016/S0926-6690(02)00098-5

Patil PD, Gude VG, Deng S (2009) Biodiesel production from Jatropha curcas, waste cooking, and camelina sativa oils. Ind Eng Chem Res 48(24):10850–10856. doi:10.1021/ie901146c

Leung DYC, Wu X, Leung MKH (2010) A review on biodiesel production using catalyzed transesterification. Appl Energy 87(4):1083–1095. doi:10.1016/j.apenergy.2009.10.006

Barnwal BK, Sharma MP (2005) Prospects of biodiesel production from vegetable oils in India. Renew Sustain Energy Rev 9(4):363–378. doi:10.1016/j.rser.2004.05.007

Demirbas A (2008) Relationships derived from physical properties of vegetable oil and biodiesel fuels. Fuel 87(8–9):1743–1748. doi:10.1016/j.fuel.2007.08.007

Demirbas A (2009) Production of biodiesel fuels from linseed oil using methanol and ethanol in non-catalytic SCF conditions. Biomass Bioenergy 33(1):113–118. doi:10.1016/j.biombioe.2008.04.018

Azad A, Uddin SA, Alam M (2013) Experimental study of DI diesel engine performance using biodiesel blends with kerosene. Int J Energy Environ 4(2):265–278

Sanjid A, Kalam MA, Masjuki HH, Rahman SMA, Abedin MJ (2014) Combustion, performance and emission characteristics of a DL diesel engine fueled with Brassica juncea methyl ester and its blends. RSC Adv 4(70):36973–36982. doi:10.1039/C4RA05085A

Lang X, Dalai AK, Bakhshi NN, Reaney MJ, Hertz PB (2001) Preparation and characterization of bio-diesels from various bio-oils. Bioresour Technol 80(1):53–62. doi:10.1016/S0960-8524(01)00051-7

Srivastava A, Prasad R (2000) Triglycerides-based diesel fuels. Renew Sustain Energy Rev 4(2):111–133. doi:10.1016/S1364-0321(99)00013-1

Demirbas A (2005) Biodiesel production from vegetable oils via catalytic and non-catalytic supercritical methanol transesterification methods. Prog Energy Combust Sci 31(5–6):466–487. doi:10.1016/j.pecs.2005.09.001

Sivaramakrishnan K, Ravikumar P (2011) Determination of higher heating value of biodiesels. Int J Eng Sci Technol (IJEST) 3(11):7981–7987

Tulip DRE, Radha K (2013) Production of biodiesel from mustard oil its performance and emission characterization on internal combustion engine. Adv Eng Appl Sci 3(3):37–42

Zahir E, Saeed R, Hameed MA, Yousuf A Study of physicochemical properties of edible oil and evaluation of frying oil quality by Fourier Transform-Infrared (FT-IR) Spectroscopy. Arab J Chem doi:10.1016/j.arabjc.2014.05.025

Fasina OO, Colley Z (2008) Viscosity and specific heat of vegetable oils as a function of temperature: 35–180° C. Int J Food Prop 11(4):738–746. doi:10.1080/10942910701586273

Hong IK, Lee JR, Lee SB Fuel properties of canola oil and lard biodiesel blends: Higher heating value, oxidative stability, and kinematic viscosity. J Ind Eng Chem doi:10.1016/j.jiec.2014.07.027

Ciubota-Rosie C, Ruiz JR, Ramos MJ, Pérez Á (2013) Biodiesel from Camelina sativa: a comprehensive characterisation. Fuel 105:572–577. doi:10.1016/j.fuel.2012.09.062

Waraich EA, Ahmed Z, Ahmad R, Ashraf MY, Naeem MS, Rengel Z (2013) Camelina sativa, a climate proof crop, has high nutritive value and multiple-uses: a review. Aust J Crop Sci 7(10):1551

Sanford SD, White JM, Shah PS, Wee C, Valverde MA, Meier GR (2009) Feedstock and biodiesel characteristics report. Renew Energy Group 416:1–136

Singh SP, Singh D (2010) Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: a review. Renew Sustain Energy Rev 14(1):200–216. doi:10.1016/j.rser.2009.07.017

Bannikov M Combustion and emission characteristics of Mustard biodiesel. In: 6th International Advanced Technologies Symposium (IATS’11), Turkey, 2011. pp 1–5

Choo W-S, Birch J, Dufour J-P (2007) Physicochemical and quality characteristics of cold-pressed flaxseed oils. J Food Compos Anal 20(3–4):202–211. doi:10.1016/j.jfca.2006.12.002

Czaplicki S, Ogrodowska D, Derewiaka D, Tańska M, Zadernowski R (2011) Bioactive compounds in unsaponifiable fraction of oils from unconventional sources. Eur J Lipid Sci Technol 113(12):1456–1464. doi:10.1002/ejlt.201000410

El-Beltagi HS, Salama ZA, El-Hariri DM (2011) Variations in oil and some phytochemical contents in flaxseed cultivars (Linum usitatissimum L.). EJEAFChe 10(8):2711–2721

Teh S-S, Birch J (2013) Physicochemical and quality characteristics of cold-pressed hemp, flax and canola seed oils. J Food Compos Anal 30(1):26–31. doi:10.1016/j.jfca.2013.01.004

Maricán A, Ahumada I, Richter P (2012) Multivariate optimization of pressurized solvent extraction of alkylphenols and alkylphenol ethoxylates from biosolids. J Braz Chem Soc 23(2):267–272

Joana Gil-Chávez G, Villa JA, Fernando Ayala-Zavala J, Basilio Heredia J, Sepulveda D, Yahia EM, González-Aguilar GA (2013) Technologies for extraction and production of bioactive compounds to be used as nutraceuticals and food ingredients: an overview. Compr Rev Food Sci Food Saf 12(1):5–23. doi:10.1111/1541-4337.12005

Maryott AA, Smith ER (1951) Table of dielectric constants of pure liquids. National Bureau of Standards circular 514, vol iv, 44 p. U.S. Govt. Print. Off., Washington

Marshall WL (2008) Dielectric Constant of Water Discovered to be Simple Function of Density over Extreme Ranges from–35 to + 600° C and to 1200 MPa (12000 Atm.), Believed Universal. Nature. doi:10.1038/npre.2008.2472.1

Wissam Z, Ghada B, Wassim A, Warid K (2012) Effective extraction of polyphenols and proanthocyanidins from pomegranate’s peel. Int J Pharm Pharm Sci 4(Supplement 3):675–682

Acknowledgments

The authors gratefully acknowledge the funding provided by Agricultural Experiment Station, College of Agriculture and Biological Sciences, South Dakota State University. We would also like to thank the funding agencies - NC Sun Grant, DoT, DoE, SD Oilseeds Initiative, Griffith Foundation for this research.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Lohani, U.C., Fallahi, P. & Muthukumarappan, K. Comparison of Ethyl Acetate with Hexane for Oil Extraction from Various Oilseeds. J Am Oil Chem Soc 92, 743–754 (2015). https://doi.org/10.1007/s11746-015-2644-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2644-1