Abstract

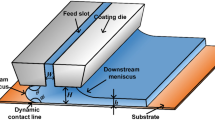

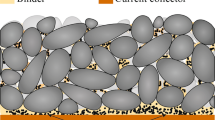

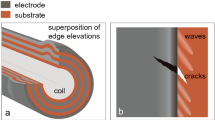

Large-scale secondary lithium-ion batteries could be a key technology to compensate for the inconsistent energy supply of renewable sources. However, their manufacture is still very costly. In particular, the intermittent slot die coating of the battery electrodes is the speed-limiting and thus cost-driving process. In this field, various patents have been granted, and most in-house coating equipment was developed in industry. These technologies are often optimized empirically, since intermittent slot die coating is not mentioned in the scientific literature. In this work, we investigate the dominating and limiting mechanisms for intermittent slot die coating of non-Newtonian battery slurries. To characterize the process, we measured the system and die pressure and the associated wet film thickness. To build a common basis for all established technologies, we reduced the coating system to a syringe pump, a bypass valve, and a slot die. Our results show the direct link between casted film and pressure distribution within the coating. To reduce leveling times between the coating and interruption phases of an intermittent coating, a model was developed to predict the optimum pressure levels. It was found that different pressure levels during the coating and interruption phases lead to film break-ups or downstream die swelling, and thus limit the whole process.

Similar content being viewed by others

Abbreviations

- d :

-

Internal pipe diameter (mm)

- h :

-

Height (z-axis) (μm)

- l :

-

Length (x-axis) (mm)

- p :

-

Pressure (mbar)

- u :

-

Speed (m/min)

- v :

-

Volume flow (mL/min)

- w :

-

Width (y-axis) (mm)

- γ :

-

Deformation (%)

- \(\dot{\gamma }\) :

-

Shear rate (1/s)

- ε :

-

Power law exponent (–)

- κ :

-

Consistency factor (Pa sn)

- τ :

-

Shear stress (Pa)

- C:

-

Coating

- D:

-

Downstream lip

- G:

-

Gap

- I:

-

Interruption

- P:

-

Pipe

- S:

-

Slot

- W:

-

Web

- WP:

-

Waste-pipe

References

El Bassam, N, Maegaard, P, Schlichting, M, Distributed Renewable Energies for Off-Grid Communities, Strategies and Technologies toward Achieving Sustainability in Energy Generation and Supply. Elsevier, Amsterdam, 2012

Second Report of NEMP. National Electric Mobility Platform, Berlin, 2011

Konrad, M, Zellentechnologien. In: Photovoltaik, pp. 113–147. Carl Hanser Verlag GmbH & Co. KG, Munchen, 2013.

Hau, E, Wind Turbines: Fundamentals, Technology, Applications, Cost-Efficiency. Springer, Berlin, 2008

Nazri, GA, Pistoia, G, Lithium Batteries: Science and Technology. Springer, Berlin, 2003

RBS Consultants, Powertrain 2020-The Li-Ion Battery Value Chain—Trends and Implications. Roland Berger Strategy Consultants, Stuttgart, 2011

Yoshio, M, Brodd, RJ, Kozawa, A, Lithium-Ion Batteries: Science and Technologies. Springer, Berlin, 2009

Daniel, C, “Materials and Processing for Lithium-Ion Batteries.” JOM, 60 (9) 43–48 (2008)

Kaiser, J, et al., “Prozess- und Produktentwicklung von Elektroden für Li-Ionen-Zellen [Process and product development of electrodes for lithium-ion cells].” Chem. Ing. Tech., 86 (5) 695–706 (2014)

Zheng, H, et al., “Calendering effects on the physical and electrochemical properties of Li[Ni1/3Mn1/3Co1/3]O2 cathode.” J. Power Sources, 208 52–57 (2012)

Schmitt, M, Scharfer, P, Schabel, W, “Stripe and Pattern Coatings of Slot Die Coated Battery Electrodes—Investigation of Edge Effects (Talk).” European Coating Symposium 2013. Mons, Belgium, 2013

Kistler, SF, Schweizer, PM, Liquid Film Coating: Scientific Principles and Their Technological Implications. Chapman & Hall, New York, 1997

Cohen, ED, Gutoff, EB, Modern Coating and Drying Technology. Wiley, New York, 1992

Romero, OJ, et al., “Low-flow limit in slot coating of dilute solutions of high molecular weight polymer.” J. Non-Newton. Fluid Mech., 118 (2–3) 137–156 (2004)

Romero, OJ, Scriven, LE, Carvalho, MS, “Slot coating of mildly viscoelastic liquids.” J. Non-Newton. Fluid Mech., 138 (2–3) 63–75 (2006)

Chang, Y-R, Lin, C-F, Liu, T-J, “Start-up of slot die coating.” Polym. Eng. Sci., 49 (6) 1158–1167 (2009)

Iwashita, Y, Endo, S, Morimoto, K, “Intermittent Coating Method and Apparatus Therefor.” Google Patents: US 5989622 A, 1999

Watanabe, M, et al., “Intermittent Coating Apparatus, Intermittent Coating Method and Manufacturing Method of Battery Electrodes, and Non Aqueous Electrolyte Cell.” Google Patents: EP 0720872 B1, 1996

Shinozaki, K, Sakai, Y, “Coating Apparatus for Applying Coating Material Intermittently to Substrate.” Google Patents: US 6641671 B2, 2003

Masuda, N, Watanabe, M, “Intermittent Coating Apparatus and Intermittent Coating Method.” Google Patents: US 7105203 B1, 2006

Sakai, Y, Yoshikawa, T, Ide, A, “Intermittent Coating System and Intermittent Coating Method.” Google Patents: US 6455105 B1, 2002

Schmitkons, JW, et al., “Snuff Back Controlled Coating Dispensing Apparatus and Methods.” Google Patents: US 5733597 A, 1998

Janssen, F, “Coating Nozzle for Intermittent Application of fluid Medium to Substrate, has Sealing Unit Arranged in Channel, so that Channel is Opened and Closed to Produce Intermittent Application of Medium in Transporting Direction.” Kg, KGC (ed.) Google Patents: DE 102010017965 A1, 2011.

Huth, A, Sekler, R, “Switchable slot valve for a coating system, coating system and coating method.” Kg, VVMFMC (ed) Google Patents: DE 102012217683 B3, 2014.

Szczepaniak, W, Janssen, F, Blum, J, “Vorrichtung zum präzisen linearen Verstellen eines Maschinenteils.” Kg, KGC (ed.) Google Patents: DE 102012110305 A1, 2014

De Vries, I, “Intermittent Slot Die Coating of Low Viscous Solutions.” In: 17th International Coating Science and Technology Symposium. International Society of Coating Science and Technology, San Diego, CA, 2014

Schmitt, M, et al., “Break-Up Phenomena in Multilayer Slot Die Coating of Lithium-Ion Batteries (Poster).” In: European Coating Symposium 2013. Mons, Belgium, 2013

Schmitt, M, et al., “Slot-die processing of lithium-ion battery electrodes—Coating window characterization.” Chem. Eng. Process., 68 32–37 (2013)

Schmitt, M, Scharfer, P, Schabel, W, “Slot die coating of lithium-ion battery electrodes: investigations on edge effect issues for stripe and pattern coatings.” J. Coat. Technol. Res., 11 57–63 (2014)

Chemieingenieurwesen, V-GVu, Gesellschaft, V, VDI Heat Atlas. Springer, Berlin, 2010

Dongari, N, Sambasivam, R, Durst, F, “Slot coaters operating in their bead mode.” Coating, 11 1–6 (2007)

Lee, SH, et al., “Operability coating windows and frequency response in slot coating flows from a viscocapillary model.” Chem. Eng. Sci., 66 (21) 4953–4959 (2011)

Ruschak, KJ, “Limiting flow in pre-metered coating device.” Chem. Eng. Sci., 31 (11) 1057–1060 (1976)

Fethi Kamisli, MER, “Perturbation method in gas-assisted power-law fluid displacement in a circular tube and a rectangular channel.” Chem. Eng. J., 75 167–176 (1999)

Acknowledgments

This work was supported by the “The Central Innovation Program SME” (ZIM), Funding-No. KF2840205FH3, by the German Federal Ministry for Economic Affairs and Energy (BMWi). Part of this work has been supported in the frame of the project Competence E (KIT) by the German Federal Ministry of Economics and Technology on the basis of a decision by the German Bundestag (Funding Nr. 03ET6016). The authors would like to thank all involved mechanics, assistants, and the students Miriam Vogt, Paul Kitz, Sandro Spiegel, Orhan Keskin, and Julian Klemens for their supporting work and building up of the experimental set-up. We specially thank Valentin Wenzel and Steffen Schmelzle (KIT-MVM-VM) for mixing support and Boris Bitsch (KIT-MVM-AM) for rheological measurements. We also want to thank our cooperation partners at KROENERT GmbH for many constructive discussions and our partners at TSE Troller AG, Switzerland for the technical support.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was presented at the 17th International Coating Science and Technology Symposium, September 7–10, 2014, in San Diego, CA (USA).

Rights and permissions

About this article

Cite this article

Schmitt, M., Diehm, R., Scharfer, P. et al. An experimental and analytical study on intermittent slot die coating of viscoelastic battery slurries. J Coat Technol Res 12, 927–938 (2015). https://doi.org/10.1007/s11998-015-9717-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9717-9