Abstract

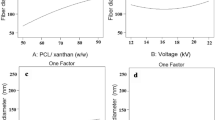

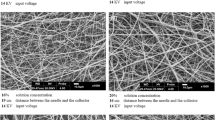

The aim of this work is the manufacturing of non-woven fabrics to be used as Filtering media. These fabrics were produced from polyacrilonitrile (PAN) and \(\upbeta \)-cyclodextrin (\(\upbeta \)-CD) solutions in dimethylsulfoxide using a horizontal electrospinning system with a flat collecting screen. The information from the experiments was statistically analyzed in order to define the process parameters (PAN concentration in solution, volumetric flow and applied voltage) needed for obtaining fibers with the smallest average diameters. First, PAN fibers were produced following a full factorial \(3^{3}\) experimental design and this information was used for preparing the corresponding Response Surfaces needed to define the best conditions for the production of PAN/\(\upbeta \)-CD nonwoven fabrics. The viscosity of the polymer solutions was analyzed using a rotational rheometer and a pseudoplastic behavior was observed, the diameter of the obtained nanofibers was determined using scanning electron microscopy. At the end, the polymer concentration (viscosity) and the volumetric flow rate were selected as the most statistically significant factors affecting the fiber diameter. Besides, uniform PAN and PAN/\(\upbeta \)-CD nanofibers with average fiber diameters between 200 and 500 nm were obtained.

Similar content being viewed by others

References

Huang, Z.-M., Zhang, Y.-Z., Kotaki, M., Ramakrishna, S.: A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 63, 2223–2253 (2003)

Hutten, I.M.: Handbook of nonwoven filter media. Elsevier (2007)

Dalton, P.D., Grafahrend, D., Klinkhammer, K., Klee, D., Mller, M.: Electrospinning of polymer melts: phenomenological observations. Polymer 48, 6823–6833 (2007)

Wang, X., Huang, Z.: Melt-electrospinning of PMMA. Chin. J. Polym. Sci. 28, 45–53 (2010)

Nayak, R., Kyratzis, I.L., Truong, Y.B., Padhye, R., Arnold, L.: Melt-electrospinning of polypropylene with conductive additives. J. Mater. Sci. 47, 6387–6396 (2012)

Ramakrishna, S.: An introduction to electrospinning and nanofibers. World Scientific, Singapore (2005)

Deitzel, J.M., Kleinmeyer, J., Harris, D., Beck Tan, N.C.: The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer 42, 261–272 (2001)

Bhardwaj, N., Kundu, S.C.: Electrospinning: a fascinating fiber fabrication technique. Biotechnol. Adv. 28, 325–347 (2010)

Luo, C.J., Nangrejo, M., Edirisinghe, M.: A novel method of selecting solvents for polymer electrospinning. Polymer 51, 1654–1662 (2010)

Fischer, X., Nadeau, J.P.: Interactive Design: Then and Now. Research in Interactive Design, vol. 3, p. 15. Springer (2011)

Yrdem, O.S., Papila, M., Mencelolu, Y.Z.: Effects of electrospinning parameters on polyacrylonitrile nanofiber diameter: an investigation by response surface methodology. Mater. Des. 29, 34–44 (2008)

Nasouri, K., Bahrambeygi, H., Rabbi, A., Shoushtari, A.M., Kaflou, A.: Modeling and optimization of electrospun PAN nanofiber diameter using response surface methodology and artificial neural networks. J. Appl. Polym. Sci. 126, 127–135 (2012)

Ziabari, M., Mottaghitalab, V., Haghi, A.K.: A new approach for optimization of electrospun nanofiber formation process. Korean J. Chem. Eng. 27, 340–354 (2010)

Vignes, R.: Dimethyl Sulfoxide (DMSO): a new clean, unique, superior solvent. American Chemical Society Annual Meeting. pp. 120 (2000)

Kim, S.S., Lee, J.: Antibacterial activity of polyacrylonitrilechitosan electrospun nanofibers. Carbohydr. Polym. 102, 231–237 (2014)

Gktepe, F.: Comparative analysis of various electrospinning methods of nanofibre formation. Fibers Text. East. Eur. 17, 13–19 (2009)

Gliciska, E., Gutarowska, B., Brycki, B., Kruciska, I.: Electrospun polyacrylonitrile nanofibers modified by quaternary ammonium salts. J. Appl. Polym. Sci. 128, 767–775 (2013)

Kurban, Z., Lovell, A., Jenkins, D., Bennington, S., Loader, I., Schober, A., Skipper, N.: Turbostratic graphite nanofibres from electrospun solutions of PAN in dimethylsulphoxide. Eur. Polym. J. 46, 1194–1202 (2010)

Lewandowski, A., Majchrzak, I.: Polyacrylonitrile-DMSO-AgClO4 solid polymer electrolyte. Electrochim. Acta. 42, 267–270 (1997)

Nataraj, S.K., Yang, K.S., Aminabhavi, T.M.: Polyacrylonitrile-based nanofibersA state-of-the-art review. Prog. Polym. Sci. 37, 487–513 (2012)

Szejtli, J.: Introduction and general overview of cyclodextrin chemistry. Chem. Rev. 98, 1743–1754 (1998)

Uyar, T., Havelund, R., Nur, Y., Balan, A., Hacaloglu, J., Toppare, L., Besenbacher, F., Kingshott, P.: Cyclodextrin functionalized poly(methyl methacrylate) (PMMA) electrospun nanofibers for organic vapors waste treatment. J. Membr. Sci. 365, 409–417 (2010)

Uyar, T., Besenbacher, F.: Electrospinning of cyclodextrin functionalized polyethylene oxide (PEO) nanofibers. Eur. Polym. J. 45, 1032–1037 (2009)

Uyar, T., Havelund, R., Nur, Y., Hacaloglu, J., Besenbacher, F., Kingshott, P.: Molecular filters based on cyclodextrin functionalized electrospun fibers. J. Membr. Sci. 332, 129–137 (2009)

Menges, G., Wortberg, F., Michaeli, W. Kunststoffe: 68–71 (1978)

Montgomery, D.C., Runger, G.C.: Applied statistics and probability for engineers. Wiley, New York (2003)

Cramariuc, B., Cramariuc, R., Scarlet, R., Manea, L.R., Lupu, I.G., Cramariuc, O.: Fiber diameter in electrospinning process. J. Electrost. 71, 189–198 (2013)

Jarusuwannapoom, T., Hongrojjanawiwat, W., Jitjaicham, S., Wannatong, L., Nithitanakul, M., Pattamaprom, C., Koombhongse, P., Rangkupan, R., Supaphol, P.: Effect of solvents on electro-spinnability of polystyrene solutions and morphological appearance of resulting electrospun polystyrene fibers. Eur. Polym. J. 41, 409–421 (2005)

Acknowledgments

Authors would like to thank to EAFIT University for the financial support of this research. Additionally, special acknowledgments are dedicated to professor Mauricio Arroyave and Aida Arnedo from EAFIT University for all the support for obtaining the SEM images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Noreña-Caro, D., Alvarez-Láinez, M. Experimental design as a tool for the manufacturing of filtering media based on electrospun polyacrylonitrile/\(\upbeta \)-cyclodextrin fibers. Int J Interact Des Manuf 10, 153–164 (2016). https://doi.org/10.1007/s12008-014-0241-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-014-0241-4