Abstract

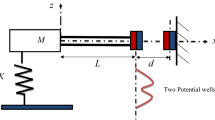

In this paper, the goal is to design a two degrees of freedom piezoelectric plate energy harvester which can harvest the energy from external in-plane harmonic force coming from different directions. The most challenging problem in this case is the charge cancellation due to combination of tension and compression in different parts of the plate. Therefore, topology optimization method is utilized to find the best possible layout and polarization profile of the piezoelectric plate to maximize the electrical output and to overcome the problem of charge cancellation. To do so, a detailed two dimensional finite element modelling of the piezoelectric material suitable for topology optimization is presented primarily. The topology optimization algorithm is established based on the finite element model to have minimum amount of numerical instabilities. To follow the optimized polarization profile, the electrode in top surface of the piezoelectric plate is separated to two sections that can have potentials with different sign on the same surface. Numerical simulation by COMSOL Multiphysics finite element software and experimental investigation on the fabricated designs demonstrated that the optimized design is highly superior to the classical full plate in terms of produced voltage and electrical power while having less volume of piezoelectric material.

Similar content being viewed by others

References

de Almeida BV, Cunha DC, Pavanello R (2019) Topology optimization of bimorph piezoelectric energy harvesters considering variable electrode location. Smart Materials and Structures

Amlashi AH, Mohand-Ousaid A, Rakotondrabe M (2019) Topology optimization of piezoelectric plate energy harvester under external in-plan force considering different boundary conditions. In: 2019 International conference on manipulation, automation and robotics at small scales (MARSS). IEEE, pp 1–6

Andreassen E, Clausen A, Schevenels M, Lazarov BS, Sigmund O (2011) Efficient topology optimization in matlab using 88 lines of code. Struct Multidiscip Optim 43(1):1–16

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224

Bendsøe MP, Sigmund O (1999) Material interpolation schemes in topology optimization. Arch Appl Mech 69(9-10):635–654

Bendsoe MP, Sigmund O (2013) Topology optimization theory, methods and applications. Springer Science & Business Media

Cha Y, Hong S (2016) Energy harvesting from walking motion of a humanoid robot using a piezoelectric composite. Smart Mater Struct 25(10):10LT01

Chamanian S, Ulusan H, Koyuncuoglu A, Muhtaroglu A, Kulah H (2018) An adaptable interface circuit with multi-stage energy extraction for low power piezoelectric energy harvesting mems. IEEE Transactions on Power Electronics

Chen Q, Zhang X, Zhu B (2019) A 213-line topology optimization code for geometrically nonlinear structures. Struct Multidiscip Optim 59(5):1863–1879

Harne R, Wang K (2013) A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater Struct 22(2):023001

Hutton DV, Wu J (2004) Fundamentals of finite element analysis, vol 1. McGraw-hill, New York

Junior CDM, Erturk A, Inman DJ (2009) An electromechanical finite element model for piezoelectric energy harvester plates. J Sound Vib 327(1–2):9–25

Khadraoui S, Rakotondrabe M, Lutz P (2014) Optimal design of piezoelectric cantilevered actuators with guaranteed performances by using interval techniques. Trans Mechatron 19(5):1660–1668

Kim HS, Kim J, Kim J (2011) A review of piezoelectric energy harvesting based on vibration. Int J Precis Eng Manuf 12(6):1129–1141

Kim SG, Priya S, Kanno I (2012) Piezoelectric mems for energy harvesting. MRS Bull 37(11):1039–1050

Kögl M, Silva EC (2005) Topology optimization of smart structures: design of piezoelectric plate and shell actuators. Smart Mater Struct 14(2):387

Lerch R (1990) Simulation of piezoelectric devices by two-and three-dimensional finite elements. IEEE Trans Ultrason Ferroelectr Frequency Control 37(3):233–247

Lin ZQ, Gea HC, Liu ST (2011) Design of piezoelectric energy harvesting devices subjected to broadband random vibrations by applying topology optimization. Acta Mech Sinica 27(5):730

Muralt P (1997) Piezoelectric thin films for mems. Integr Ferroelectr 17(1-4):297–307

Noh JY, Yoon GH (2012) Topology optimization of piezoelectric energy harvesting devices considering static and harmonic dynamic loads. Adv Eng Softw 53:45–60

Rabenorosoa K, Rakotondrabe M (2015) Performances analysis of piezoelectric cantilever based energy harvester devoted to mesoscale intra-body robot. In: Next-generation robotics II; and machine intelligence and bio-inspired computation: theory and applications IX, vol 9494. International Society for Optics and Photonics, p 94940E

Rakotondrabe M (2011) Performances inclusion for stable interval systems, pp 4367–4372

Rakotondrabe M (2013) Design of piezoelectric actuators with guaranteed performances using the performances inclusion theorem and interval tools, a Chapter in ’Smart materials-based actuators at the micro/nano-scale: characterization, control and applications’. Springer

Rupp CJ, Evgrafov A, Maute K, Dunn ML (2009) Design of piezoelectric energy harvesting systems: a topology optimization approach based on multilayer plates and shells. J Intell Mater Syst Struct 20(16):1923–1939

Salas R, Ramírez F, Montealegre-Rubio W, Silva E, Reddy J (2018) A topology optimization formulation for transient design of multi-entry laminated piezocomposite energy harvesting devices coupled with electrical circuit. Int J Numer Methods Eng 113(8):1370–1410

Salazar R, Taylor G, Khalid M, Abdelkefi A (2018) Optimal design and energy harvesting performance of carangiform fish-like robotic system. Smart Mater Struct 27(7):075045

Schlinquer T, Mohand-Ousaid A, Rakotondrabe M (2017) Optimal design of a unimorph piezoelectric cantilever devoted to energy harvesting to supply animal tracking devices. IFAC-PapersOnLine 50(1):14600–14605

Schlinquer T, Mohand-Ousaid A, Rakotondrabe M (2018) Displacement amplifier mechanism for piezoelectric actuators design using simp topology optimization approach. In: IEEE int conference on robotics and automation. IEEE, pp 1–7

Sigmund O (2001) A 99 line topology optimization code written in matlab. Struct Multidiscip Optim 21 (2):120–127

Silva EN, Fonseca JO, Kikuchi N (1997) Optimal design of piezoelectric microstructures. Comput Mech 19(5):397–410

Silva EN, Nishiwaki S, Kikuchi N (2000) Topology optimization design of flextensional actuators. IEEE Trans Ultrasonics Ferroelectr Frequency Control 47(3):657–671

Svanberg K (1987) The method of moving asymptotes—a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373

Toprak A, Tigli O (2014) Piezoelectric energy harvesting: state-of-the-art and challenges. Appl Phys Rev, 1(3)

Zhang X, Kang Z (2014) Dynamic topology optimization of piezoelectric structures with active control for reducing transient response. Comput Methods Appl Mech Eng 281:200– 219

Zhang X, Kang Z (2014) Topology optimization of piezoelectric layers in plates with active vibration control. J Intell Mater Syst Struct 25(6):697–712

Zheng B, Chang CJ, Gea HC (2009) Topology optimization of energy harvesting devices using piezoelectric materials. Struct Multidiscip Optim 38(1):17–23

Zhu B, Zhang X, Zhang H, Liang J, Zang H, Li H, Wang R (2020) Design of compliant mechanisms using continuum topology optimization: a review. Mech Mach Theory 143:103622

Zhu D, Tudor MJ, Beeby SP (2009) Strategies for increasing the operating frequency range of vibration energy harvesters: a review. Measur Sci Technol 21(2):022001

Acknowledgments

This work has been supported by the national CODE-TRACK project (ANR-17-CE05-0014-01, Control theory tools for optimal design of piezoelectric energy harvesters devoted to birds tracking devices). This work has also been partially supported by the Bourgogne Franche-Comté region project COMPACT.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Plane-stress assumption for piezoelectric plate

Appendix: Plane-stress assumption for piezoelectric plate

Based on the full 3D piezoelectric constitutive equation [17] the mechanical stiffness matrix, piezoelectric matrix and permittivity matrix for a transverse isotropic material like PZT class can be written as

Now by considering the plane-stress assumption all the nominal stresses perpendicular to the xy plane is zero [11]. Therefore, the elements of the reduced order matrices mentioned in Eq. 2 can be derived as [12]

The coefficients of the PZT-5H which is fabricated for experimental investigation and the calculated plane-stress assumption is mentioned in Table 2.

Rights and permissions

About this article

Cite this article

Homayouni-Amlashi, A., Mohand-Ousaid, A. & Rakotondrabe, M. Topology optimization of 2DOF piezoelectric plate energy harvester under external in-plane force. J Micro-Bio Robot 16, 65–77 (2020). https://doi.org/10.1007/s12213-020-00129-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12213-020-00129-0