Abstract

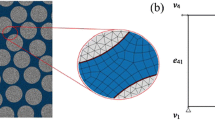

The carbon fiber/epoxy matrix interface plays an important role in the behavior and damage onset of unidirectional fiber reinforced epoxy matrix composites and accurate modeling techniques are needed to study the effects of this complex region on the composite response. In this work, a microscopic cohesive zone model (MCZM) based on atomic potential energy is established for the interface. A multiscale analysis method is proposed for predicting the transverse mechanical properties of unidirectional fiber composites: (1) At the microscale, MCZM is established for the interface; (2) At the mesoscale, a unit cell model is established for the fiber, matrix and interface; and (3) At the macroscale, the homogenization method, failure criteria and damage degradation models are used for predicting the transverse mechanical properties. Subsequently, the transverse mechanical properties and the damage evolution process are simulated with the multiscale analysis method. A comparison between the simulations and experiments shows that: (1) The maximum errors of the predicted transverse modulus and transverse strength are −4.45 % and −1.28 %, respectively; and (2) MCZM can reflect the nonlinearity of epoxy matrix composite materials. Moreover, the effects of the interfacial strength on the macroscopic transverse mechanical properties and the damage onset are analysed. The simulation results show that: (1) The interfacial strength has a more significant effect on the transverse strength and ultimate strain than on the transverse modulus; (2) Decreasing the interfacial strength has a greater effect on the transverse modulus, strength and ultimate strain than increasing the interfacial strength; and (3) The interfacial strength can change the damage onset.

Similar content being viewed by others

References

J. M. Weng, W. D. Wen, H. T. Cui, and B. Chen, Acta Astronaut, 147, 133 (2018).

W. Z. Wang, Y. H. Dai, C. Zhang, X. S. Gao, and M. Y. Zhao, Materials, 9, 624 (2016).

N. Buannic and P. Cartraud, Int. J. Solids Stuct., 38, 7139 (2001).

Q. Qin and Q. Yang, “Macro-Micro-theory on Multifield Coupling Behavior of Heterogeneous Materials”, 1st ed., pp.1–6, Higher Education Press, Beijing, China, 2008.

S. Ghosh and S. N. Mukhopadhyay, Comput. Struct., 41, 245 (1991).

S. Ghosh, K. Lee, and P. Raghavan, Int. J. Solids Stuct., 38, 2335 (2001).

J. Aboudi, Mech. Adv. Mater. Struct., 11, 38 (2004).

C. T. Sun and R. S. Vaidya, Compos. Sci. Technol., 56, 171 (1996).

Y. L. Chen, Y. Ma, F. Pan, and S. T. Wang, Chinese J. Solid Mech., 39, 1 (2018).

J. Aboudi, Int. J. Solids Struct., 17, 1005 (1981).

M. Paley and J. Aboudi, Mech. Mater., 14, 127 (1992).

H. Li and B. Zhang, Int. J. Plasticity, 65, 22 (2015).

Z. Xia, F. Ellyin, and Y. Zhang, Int. J. Solids Struct., 40, 1907 (2003).

R. M. Hackett, Int. J. Numer. Meth. Eng., 103, 413 (2015).

A. G. Prodromou, S. V. Lomov, and I. Verpoest, Compos. Struct., 93, 1290 (2011).

Y. D. Sha, G. Y. Ding, J. G. Tian, L. Luo, and X. C. Luan, J. Aerospace Power, 33, 2324 (2018).

G. Alfano and M. A. Crisfield, Int. J. Numer. Meth. Eng., 50, 1701 (2001).

X. P. Xu and A. Needleman, J. Mech. Phys. Solids, 42, 1397 (1994).

X. Wang, J. Zhang, Z. Wang, S. Zhou, and X. Sun, Mater. Des., 32, 3486 (2011).

G. Han, Z. D. Guan, Z. S. Li, M. Zhang, T. Y. Bian, and S. Y. Du, Appl. Compos. Mater., 22, 289 (2015).

C. C. Pessan, B. Lima, and E. R. Leite, Nanoscale Advances, 1, 937 (2019).

C. M. Hadden, D. R. Klimek-McDonald, E. Pineda, J. King, A. M. Reichanadter, I. Miskioglu, G. Sh, and G. M. Odgard, Carbon, 95, 100 (2015).

J. P. Johnston, B. Koo, N. Subramanian, and A. Chattopadhyay, Compos. Part B-Eng., 111, 27 (2017).

A. A. Mousavi, B. Arash, X. Y. Zhuang, and T. Rabczuk, Compos. Part B-Eng., 95, 404 (2016).

H. Shin, S. Chang, S. Yang, B. D. Youn, and M. Cho, Compos. Part B-Eng., 87, 120 (2016).

Y. Zhang, F. Xu, C. Zhang, J. Wang, Z. Jia, D. Hui, and Y. Qiu, Compos. Part B-Eng., 99, 358 (2016).

A. K. Gupta and S. P. Harsha, Compos. Part B-Eng., 95, 172 (2016).

H. S. Bedi, M. Tiwari, and P. Agnihotri, Carbon, 132, 181 (2018).

A. Bensoussan and J. Lions, “Asymptotic Analysis for Periodic Structures”, 7th ed., pp.19–23, AMS Chelsea Publishing, Providence, America, 2011.

D. Cioranescu and J. S. Paulin, J. Math. Anal. Appl., 71, 590 (1979).

O. A. Oleinik, Lect. Notes Phys., 195, 248 (1984).

E. Sanchez-Palencia, Lect. Notes Phys., 127, 45 (1980).

O. Oleinik and A. Shamaev, “Mathematical Problems in Elasticity and Homogenization”, 3rd ed., pp.119–261, North Holland., Princeton, America, 2012.

D. Blackketter, D. E. Walrath, T. K. Brien, D. M. Blackketter, D. E. Walrath, and A. C. Hansen, J. Compos. Tech. Res., 15, 136 (1993).

A. Tabiei, G. Song, and Y. Jiang, J. Thermoplast. Compos., 16, 5 (2003).

I. Ivanov and A. Tabiei, Compos. Struct., 54, 489 (2001).

A. Tabiei and I. Ivanov, Int. J. Non Linear Mech., 39, 175 (2004).

R. D. Campilho, M. D. Banea, J. A. Neto, and L. F. Silva, Int. J. Adhes Adhes, 44, 48 (2013).

A. G. Salvi, A. M. Waas, and A. Caliskan, J. Mater Sci., 43, 5168 (2008).

Y. Y. Liu and D. Y. Ge, J. Aeronaut. Mater., 18, 56 (1998).

L. A. Girifalco, M. Hodak, and R. S. Lee, Phys. Rev. B, 62, 13104 (2000).

S. J. Frankland, V. M. Harik, G. M. Odegard, D. W. Brenner, and T. S. Gates, Compos. Sci. Technol., 63, 1655 (2003).

X. F. Wang, Ph. D. Dissertation, Nanjing University of Aeronautics and Astronautics, Nanjing, 2007.

B. Zhang, Z. Yang, X. Sun, and Z. Tang, Comp. Mater. Sci., 49, 645 (2010).

Y. P. Bai, Z. Wang, and L. Q. Feng, Mater. Des., 31, 1613 (2010).

Acknowldgments

This work has been supported by the Key Laboratory of Aero-engine Thermal Environment and Structure, Ministry of Industry and Information Technology (NO. XCA1700205).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, W., Fang, L., Chen, Z. et al. A Microscopic Cohesive Zone Model and Effects of Interface on the Transverse Mechanical Properties for Composites. Fibers Polym 22, 1352–1365 (2021). https://doi.org/10.1007/s12221-021-0150-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0150-7