Abstract

Thermoelectric power generation performance is characterized on the basis of the figure of merit, which tends to be high in thermoelectric materials with high electrical conductivity and low thermal conductivity. Porous structures cause phonon scattering, which decreases thermal conductivity. In this study, we fabricated porous structures for thermoelectric devices via nano-phase separation of silica particles from a polyacrylonitrile (PAN) matrix via a sol–gel process. The porosity was determined by control of silica particle size with various the mixing ratio of tetraethylorthosilicate as the precursor of silica particles to PAN. High electrical conductivity was maintained by subsequent carbonization of the PAN matrix in spited of a high porosity. As the results, the conductive porous structures having porosity from 13.9 to 83.3 (%) was successfully fabricated, keeping their electrical conductivities.

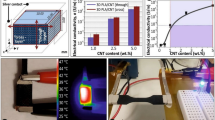

Graphical Abstract

Similar content being viewed by others

References

Naboka, O., Sanz-Velasco, A., Lundgren, P., Enoksson, P., Gatenholm, P.: Cobalt (II) chloride promoted formation of honeycomb patterned cellulose acetate films. J. Colloid Interface Sci. 367, 485 (2012)

Li, Y., Fu, Z.Y., Su, B.L.: Hierarchically structured porous materials for energy conversion and storage. Adv. Funct. Mater. 22, 4634 (2012)

Zukalova, M., Zukal, A., Kavan, L., Nazeeruddin, M.K., Liska, P., Grätzel, M.: Organized mesoporous TiO2 films exhibiting greatly enhanced performance in dye-sensitized solar cells. Nano Lett. 5, 1789 (2005)

Liu, W., Chen, Z., Zhou, G., Sun, Y., Lee, H.R., Liu, C., Yao, H., Bao, Z., Cui, Y.: 3D porous sponge-inspired electrode for stretchable lithium-ion batteries. Adv. Mater. 28, 3578 (2016)

Wolf, A., Brendel, R.: Thermal conductivity of sintered porous silicon films. Thin Solid Films 513, 385 (2006)

Snyder, G.J., Toberer, E.S.: Complex thermoelectric materials. Nat. Mater. 7, 105 (2008)

Cornett, J.E., Rabin, O.: Thermoelectric figure of merit calculations for semiconducting nanowires. Appl. Phys. Lett. 98, 182104 (2011)

Cornett, J.E., Rabin, O.: Universal scaling relations for the thermoelectric power factor of semiconducting nanostructures. Phys. Rev. B 84, 205410 (2011)

Li, J.F., Liu, W.S., Zhao, L.D., Zhou, M.: High-performance nanostructured thermoelectric materials. NPG Asia Mater. 2, 152 (2010)

Shu, J., Xia, R., Qian, J., Miao, J., Su, L., Cao, M., Lin, H., Chen, P., Chen, J.: Preparation and study on thermal conductive composites of chlorinated polyethylene rubber reinforced by boron nitride particles. Macromol. Res. 24, 640 (2016)

Kim, W., Zide, J., Gossard, A., Klenov, D., Stemmer, S., Shakouri, A., Majumdar, A.: Thermal conductivity reduction and thermoelectric figure of merit increase by embedding nanoparticles in crystalline semiconductors. Phys. Rev. Lett. 96, 045901 (2006)

Tang, J., Wang, H.-T., Lee, D.H., Fardy, M., Huo, Z., Russell, T.P., Yang, P.: Holey silicon as an efficient thermoelectric material. Nano Lett. 10, 4279 (2010)

Kim, H., Lee, J.K., Park, S.D., Ryu, B., Lee, J.E., Kim, B.S., Min, B.K., Joo, S.J., Lee, H.W., Cho, Y.-R.: Enhanced thermoelectric properties and development of nanotwins in Na-doped Bi0.5Sb1.5Te3 alloy. Electron. Mater. Lett. 12, 290 (2016)

Lee, J.H., Galli, G.A., Grossman, J.C.: Nanoporous Si as an efficient thermoelectric material. Nano Lett. 8, 3750 (2008)

Lee, S.H., Park, J.S., Lim, B.K., Mo, C.B., Lee, W.J., Lee, J.M., Hong, S.H., Kim, S.O.: Highly entangled carbon nanotube scaffolds by self-organized aqueous droplets. Soft Matter 5, 2343 (2009)

Warren, S.C., Perkins, M.R., Adams, A.M., Kamperman, M., Burns, A.A., Arora, H., Herz, E., Suteewong, T., Sai, H., Li, Z.: A silica sol–gel design strategy for nanostructured metallic materials. Nat. Mater. 11, 460 (2012)

Johnson, S.A., Ollivier, P.J., Mallouk, T.E.: Ordered mesoporous polymers of tunable pore size from colloidal silica templates. Science 283, 963 (1999)

Imhof, A., Pine, D.: Ordered macroporous materials by emulsion templating. Nature 389, 948 (1997)

Cui, L., Peng, J., Ding, Y., Li, X., Han, Y.: Ordered porous polymer films via phase separation in humidity environment. Polymer 46, 5334 (2005)

Jung, D., Cho, S.G., Moon, T., Sohn, H.: Fabrication and characterization of porous silicon nanowires. Electron. Mater. Lett. 12, 17 (2016)

Kim, S., Kwag, D.S., Lee, D.J., Lee, E.S.: Acidic pH-stimulated tiotropium release from porous poly(lactic-co-glycolic acid) microparticles containing 3-diethylaminopropyl-conjugated hyaluronate. Macromol. Res. 24, 176 (2016)

Lee, J.P., Choi, S., Park, S.: Preparation of silica nanospheres and porous polymer membranes with controlled morphologies via nanophase separation. Nanoscale Res. Lett. 7, 1 (2012)

Brinker, C.J., Keefer, K.D., Schaefer, D.W., Ashley, C.S.: Sol-gel transition in simple silicates. J. Non Cryst. Solids 48, 47 (1982)

Nakanishi, K.: Pore structure control of silica gels based on phase separation. J. Porous Mat. 4, 67 (1997)

Tan, L., Pan, D., Pan, N.: Gelation behavior of polyacrylonitrile solution in relation to aging process and gel concentration. Polymer 49, 5676 (2008)

Zhou, Z., Lai, C., Zhang, L., Qian, Y., Hou, H.: Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties. Polymer 50, 2999 (2009)

Fitzer, E., Frohs, W., Heine, M.: Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 24, 387 (1986)

Rahaman, M.S.A., Ismail, A.F., Mustafa, A.: A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 92, 1421 (2007)

Nataraj, S., Yang, K., Aminabhavi, T.: Polyacrylonitrile-based nanofibers—a state-of-the-art review. Prog. Polym. Sci. 37, 487 (2012)

Chen, J., Harrison, I.: Modification of polyacrylonitrile (PAN) carbon fiber precursor via post-spinning plasticization and stretching in dimethyl formamide (DMF). Carbon 40, 25 (2002)

Cuevas, F.G., Montes, J.M., Cintas, J., Urban, P.: Electrical conductivity and porosity relationship in metal foams. J. Porous Mater. 16, 675 (2008)

Chung, W.H., Hwang, H.J., Kim, H.S.: Flash light sintered copper precursor/nanoparticle pattern with high electrical conductivity and low porosity for printed electronics. Thin Solid Films 580, 61 (2015)

Bark, H., Lee, J., Lim, H., Koo, H.Y., Lee, W., Lee, H.: Simultaneous nitrogen doping and pore generation in thermo-insulating graphene films via colloidal templating. ACS Appl. Mater. Interfaces 8, 31617 (2016)

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (NRF-2017R1A2B2010552 and 2015R1A5A7037615) and Civil Military Technology Cooperation Center (15-CM-SS-03 and 15-CM-EN-08).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S., Lee, H. Fabrication of Conductive Macroporous Structures Through Nano-phase Separation Method. Electron. Mater. Lett. 14, 83–88 (2018). https://doi.org/10.1007/s13391-018-0014-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-018-0014-5