Abstract

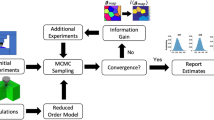

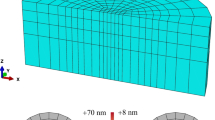

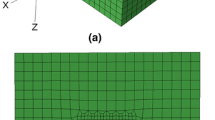

In the second part of the work, a two-step Bayesian framework is utilized for the estimation of values of the single-crystal elastic constants as well as the initial slip resistances of the different slip families in the primary α-phase components in the Ti alloys of different compositions. These estimations are based on the spherical indentation measurements presented in Part I of this series. The first step of the two-step Bayesian framework established a reduced-order model which captures the dependence of the indentation property as a function of the relevant crystal-level (intrinsic) material properties and the crystallographic lattice orientation in the indentation deformation zone. This reduced-order model is calibrated to high-fidelity results obtained from suitable crystal-plasticity finite element simulations. The second step involved the calibration of the indentation measurements obtained within the primary α-phase (from Part I of this series) to the reduced-order model established in the first step. It is demonstrated that the protocols described above result in the successful generation of a comprehensive dataset of single-crystal elastic–plastic properties across a collection of Ti alloys while accounting for the implicit uncertainties in the spherical indentation measurements.

Graphical Abstract

Similar content being viewed by others

References

Zambaldi C, Yang Y, Bieler TR, Raabe D (2012) Orientation informed nanoindentation of α-titanium: indentation pileup in hexagonal metals deforming by prismatic slip. J Mater Res 27(1):356–367

Patel D, Kalidindi S (2017) Estimating the slip resistance from spherical nanoindentation and orientation measurements in polycrystalline samples of cubic metals. Int J Plast 92:19

Castillo AR, Kalidindi SR (2019) A bayesian framework for the estimation of the single crystal elastic parameters from spherical indentation stress-strain measurements. Front Mater 6:136

Britton T, Liang H, Dunne F, Wilkinson A (2010) The effect of crystal orientation on the indentation response of commercially pure titanium: experiments and simulations. Proc R Soc A: Math, Phys Eng Sci 466(2115):695–719

Donohue BR, Ambrus A, Kalidindi SR (2012) Critical evaluation of the indentation data analyses methods for the extraction of isotropic uniaxial mechanical properties using finite element models. Acta Mater 60(9):3943–3952

Patel DK, Kalidindi SR (2016) Correlation of spherical nanoindentation stress-strain curves to simple compression stress-strain curves for elastic-plastic isotropic materials using finite element models. Acta Mater 112:295–302

MacKay DJC (1992) Bayesian interpolation. Neural Comput 4(3):415–447

MacKay DJC (1996) Hyperparameters: optimize, or integrate out? Springer, Dordrecht

Chib S, Greenberg E (1995) Understanding the Metropolis-Hastings Algorithm. Am Stat 49(4):327–335

Haario H, Saksman E, Tamminen J (2005) Componentwise adaptation for high dimensional MCMC. Comput Stat 20(2):265–273

Roberts GO, Rosenthal JS (2009) Examples of adaptive MCMC. J Comput Graph Stat 18(2):349–367

Kalidindi SR, Bronkhorst CA, Anand L (1992) Crystallographic texture evolution in bulk deformation processing of FCC metals. J Mech Phys Solids 40(3):537–569

Segurado J, Lebensohn RA, J. LLorca, C.N. (2012) Tomé, Multiscale modeling of plasticity based on embedding the viscoplastic self-consistent formulation in implicit finite elements. Int J Plast 28(1):124–140

Tomé C, Maudlin P, Lebensohn R, Kaschner G (2001) Mechanical response of zirconium—I Derivation of a polycrystal constitutive law and finite element analysis. Acta Materialia 49(15):3085–3096

Bunge HJ (1979) Texture analysis in materials science: mathematical methods. Buttersworth and Co, UK, p 376

Vlassak JJ, Nix WD (1994) Measuring the elastic properties of anisotropic materials by means of indentation experiments. J Mech Phys Solids 42(8):1223–1245

Patel DK, Al-Harbi HF, Kalidindi SR (2014) Extracting single-crystal elastic constants from polycrystalline samples using spherical nanoindentation and orientation measurements. Acta Mater 79:108–116

Yabansu YC, Patel DK, Kalidindi SR (2014) Calibrated localization relationships for elastic response of polycrystalline aggregates. Acta Mater 81:151–160

MacKay DJC (1992) Information-based objective functions for active data selection. Neural Comput 4(4):590–604

Atkinson AC (2007) Optimum experimental designs, with SAS. Oxford University Press, Oxford

Santner TJ, Williams BJ, Notz W, Williams BJ (2003) The design and analysis of computer experiments. Springer, New York

Castillo AR, Kalidindi SR (2020) Bayesian estimation of single ply anisotropic elastic constants from spherical indentations on multi-laminate polymer-matrix fiber-reinforced composite samples. Meccanica. https://doi.org/10.1007/s11012-020-01154-w

Casella G, George EI (1992) Explaining the Gibbs sampler. Am Stat 46(3):167–174

Gelfand AE, Smith AF (1990) Sampling-based approaches to calculating marginal densities. J Am Stat Assoc 85(410):398–409

Gelman A (2004) Bayesian data analysis. Chapman and Hall/CRC, Boca Raton, p 276

Higdon D, Kennedy M, Cavendish JC, Cafeo JA, Ryne RD (2004) Combining field data and computer simulations for calibration and prediction. SIAM J Sci Comput 26(2):448–466

Zeger SL, Karim MR (1991) Generalized linear models with random effects; a Gibbs sampling approach. J Am Stat Assoc 86(413):79–86

MATLAB (2016) version 9.1.0 (R2016b), The MathWorks Inc.

Roberts GO, Gelman A, Gilks WR (1997) Weak convergence and optimal scaling of random walk metropolis algorithms. Ann Appl Probab 7(1):110–120

Kalidindi S, Schoenfeld S (2000) On the prediction of yield surfaces by the crystal plasticity models for fcc polycrystals. Mater Sci Eng, A 293(1–2):120–129

Bachu V, Kalidindi SR (1998) On the accuracy of the predictions of texture evolution by the finite element technique for fcc polycrystals. Mater Sci Eng, A 257(1):108–117

Needleman A, Asaro RJ, Lemonds J, Peirce D (1985) Finite element analysis of crystalline solids. Comput Methods Appl Mech Eng 52(1):689–708

ABAQUS (2014), 6.14 Dassault Systémes Simulia Corp, Providence, RI

Huang X, Pelegri AA (2005) Mechanical characterization of thin film materials with nanoindentation measurements and FE analysis. J Compos Mater 40(15):1393–1407

Lucchini R, Carnelli D, Ponzoni M, Bertarelli E, Gastaldi D, Vena P (2011) Role of damage mechanics in nanoindentation of lamellar bone at multiple sizes: experiments and numerical modeling. J Mech Behav Biomed Mater 4(8):1852–1863

Priddy MW, Paulson NH, Kalidindi SR, McDowell DL (2017) Strategies for rapid parametric assessment of microstructure-sensitive fatigue for HCP polycrystals. Int J Fatigue 104:231–242

Bridier F, McDowell DL, Villechaise P, Mendez J (2009) Crystal plasticity modeling of slip activity in Ti–6Al–4V under high cycle fatigue loading. Int J Plast 25(6):1066–1082

Viswanathan GB, Lee E, Maher DM, Banerjee S, Fraser HL (2005) Direct observations and analyses of dislocation substructures in the α phase of an α/β Ti-alloy formed by nanoindentation. Acta Mater 53(19):5101–5115

Fisher E, Renken C (1964) Single-crystal elastic moduli and the hcp→ bcc transformation in Ti, Zr, and Hf. Phys Rev 135(2A):A482

Kim J-Y, Yakovlev V, Rokhlin S (2002) Line-focus acoustic microscopy of Ti-6242 α/β single colony: determination of elastic constants, AIP Conference Proceedings, American Institute of Physics pp. 1118–1125

Heldmann A, Hoelzel M, Hofmann M, Gan W, Schmahl WW, Griesshaber E, Hansen T, Schell N, Petry W (2019) Diffraction-based determination of single-crystal elastic constants of polycrystalline titanium alloys. J Appl Crystallogr 52(5):1144–1156

Bieler TR, Semiatin S (2001) The effect of crystal orientation and boundary misorientation on tensile cavitation during hot tension deformation of Ti-6Al-4V. Lightweight Alloys Aerosp Appl 6:161–170

Jun T-S, Zhang Z, Sernicola G, Dunne FP, Britton TB (2016) Local strain rate sensitivity of single α phase within a dual-phase Ti alloy. Acta Mater 107:298–309

Gong J, Wilkinson AJ (2009) Anisotropy in the plastic flow properties of single-crystal α titanium determined from micro-cantilever beams. Acta Mater 57(19):5693–5705

Kalidindi SR (2015) Hierarchical materials informatics: novel analytics for materials data. Elsevier, Amsterdam

Joseph VR, Gul E, Ba S (2015) Maximum projection designs for computer experiments. Biometrika 102(2):371–380

Acknowledgements

AC, AV, and SK would like to acknowledge support from the Air Force Office of Scientific Research (AFOSR) Grant FA9550-18-1-0330 (program manager, J. Tiley).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Castillo, A.R., Venkatraman, A. & Kalidindi, S.R. Mechanical Responses of Primary-α Ti Grains in Polycrystalline Samples: Part II—Bayesian Estimation of Crystal-Level Elastic-Plastic Mechanical Properties from Spherical Indentation Measurements. Integr Mater Manuf Innov 10, 99–114 (2021). https://doi.org/10.1007/s40192-021-00204-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-021-00204-9