Abstract

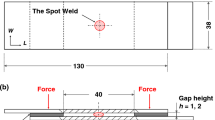

Micro series resistance spot welding (MSRSW) is a common practice to form two neighboring nuggets at the same time in industrial fabrication of precision parts, especially in EV battery pack manufacturing. However, because of the Peltier effect, unbalanced Joule heat generation results in different nugget sizes. Therefore, weld quality monitoring systems are necessary to improve weld quality. Unfortunately, no work has been reported. It is still a challenge to develop a monitoring system. A series of monitoring systems have been developed for conventional resistance spot welding (RSW). Among them, electrode movement caused by heat expansion and contraction during the welding process is an important information. GAP sensor and LVDT are major sensors used in the measurement of electrode movement. However, the physical dimension of these sensors is too huge to be applied in MSRSW. This study proposes an in-process electrode movement monitoring system for MSRSW using dual accelerometers. Two-minute accelerometers were mounted on top of each electrode holders. Thanks to its good sensitivity and frequency response characteristics, an accelerometer signal was successfully picked up and integrated twice to reflect an electrode expansion/contraction movement. The correlation between two signals was analyzed by applying the Lissajous figure technique. Experimental verification of this monitoring system has been carried out. A major finding is that dual accelerometer signal and its double-integrated signal, electrode movement, reflect thermo-physical phenomena during MSRSW process.

Similar content being viewed by others

Change history

10 December 2019

The original version of this article unfortunately contains a mistake.

References

Resistance Welder Manufacturers Association (2003) Resistance welding manual, 4th edition. Resistance Welder Manufacturers Associations, Philadelphia, PA

Gedeon SA, Sorensen CD, Ulrich KT, Eagar TW (1987) Measurement of dynamic electrical and mechanical properties of resistance spot welds. Weld J

Dickson DW, Franklin JE, Stanya A (1980) Characterization of spot welding behavior by dynamic electrical parameter monitoring. Weld J

Chien CS, Kannatey E (2002) Investigation of monitoring systems for resistance spot welding. Weld J

Hee Seok Chang (1989) In-process monitoring and control of weld nugget geometry for resistance spot welding process, doctoral thesis, Korea Advanced Institute of Science and Technology

Chang HS, Kwon HC (2011) In-process monitoring of micro resistance spot weld quality using accelerometer. J KWJS

Jou M (2003) Real-time monitoring weld quality of resistance spot welding for the fabrication of sheet metal assemblies. J Mater Process Technol

Chen JZ, Farson DF (2004) Electrode displacement measurement dynamics in monitoring of small scale resistance spot welding. Meas Sci Technol

Savage WF, Nippes EF, Wassell FA (1977) Static contact resistance of series spot welds. Weld J

Savage WF, Nippes EF, Wassell FA (1978) Dynamic contact resistance of series spot welds. Weld J

Al-Khazali HAH, Askari MR (2012) Geometrical and graphical representations analysis of Lissajous figures in rotor dynamic system. IOSR J Eng

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Lin, H.J., Chang, H.S. In-process monitoring of micro series spot welding using dual accelerometer system. Weld World 63, 1641–1654 (2019). https://doi.org/10.1007/s40194-019-00799-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00799-w