Abstract

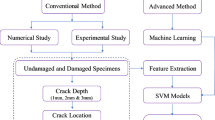

This article reports on the physics-based models for the diagnosis (detection, isolation, localization, and quantification of damages) and prognosis (prediction of the future evolution of damages) of laminated composites. The model-based and data-driven prognostic strategies are compared, followed by a summary of the most common failure modes and the failure mechanisms of laminated composite materials. Then, an overview is provided of the measurement-based empirical/phenomenological and finite element-based damage evolution models for composite materials. The techniques reviewed in the former are Paris’s law and its modified versions, stiffness degradation models, Bayesian framework (Particle filters, Bayesian inference, dynamic Bayesian networks), and minimum strain energy theory. The finite element-based models overviewed failure criteria (Hashin, Puck, stress failure criteria) and damage propagation criteria (B-K criterion, equivalent strain/displacement criterion, strain rate-dependent damage model, cohesive zone modeling, De-Cohesive Law). Due to their complex failure modes, there is no generalized global solution for the diagnostics and prognostics of composite materials. The article will serve as guidelines for the physics-based prognostics and health management (PHM) of composite materials.

Similar content being viewed by others

Data Availability

This is a review article which provides an overview of the physics-based approaches for prognosis of damage in laminated composites from the published literature. Since no measured data was used in the article, the authors would not be able to provide a data availability statement for this article.

Abbreviations

- \(a\) :

-

Crack length

- \(N\) :

-

Cumulative load/impact cycle

- f(D L):

-

Functional form corresponding to loading conditions

- ∆K :

-

Range of stress intensity factor

- ∆G :

-

Range of energy release rate

- X t :

-

Tensile failure stress of a lamina in fiber direction

- X c :

-

Compressive failure stress of a lamina in fiber direction

- Y t :

-

Tensile failure stress of a lamina normal fiber direction

- Y c :

-

Compressive failure stress of a lamina normal fiber direction

- S 12 :

-

Interlaminar shear strength

- \({\sigma }_{m}^{max}\) :

-

Maximum principal stress

- \({\sigma }_{m}^{mim}\) :

-

Minimum principal stress

- \({\theta }_{m}^{max}\) :

-

Tensile angle of rotation for the matrix crack

- \({\theta }_{m}^{mim}\) :

-

Compression angle of rotation for the matrix crack

- \({\varepsilon }_{1T}\) :

-

Failure strain of a unidirectional layer in tension

- \({\varepsilon }_{1C}\) :

-

Failure strain of a unidirectional layer in compression

- νf12 :

-

Poisson’s ratio

- m σf :

-

Mean stress magnification factor for the fibers in the × 2 direction

- γ 21 :

-

Shear strain

References

Choi, J. Y., Jeon, J. H., Lyu, J. H., et al. (2022). Current Applications and Development of Composite Manufacturing Processes for Future Mobility. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-022-00483-3

Seo, J., Kim, D. Y., Kim, D. C., et al. (2021). Recent developments and challenges on machining of carbon fiber reinforced polymer composite laminates. International Journal of Precision Engineering and Manufacturing, 22, 2027–2044.

Kim, D.-J., Lim, J., Nam, B., et al. (2021). Design and manufacture of automotive hybrid steel/carbon fiber composite b-pillar component with high crashworthiness. International Journal of Precision Engineering and Manufacturing-Green Technology, 8, 547–559.

Khalid, M. Y., Arif, Z. U., & Al, R. A. (2022). Investigation of tensile and flexural behavior of green composites along with their impact response at different energies. International Journal of Precision Engineering and Manufacturing-Green Technology, 9, 1399–1410.

Khan, A., & Kim, H. S. (2022). A brief overview of delamination localization in laminated composites. Multiscale Science and Engineering, 4, 102–110.

Hwang, S., An, Y.-K., Yang, J., et al. (2020). Remote inspection of internal delamination in wind turbine blades using continuous line laser scanning thermography. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 699–712.

Zimmermann, N., & Wang, P. H. (2020). A review of failure modes and fracture analysis of aircraft composite materials. Engineering Failure Analysis, 115, 104692.

Khalid, S., & Kim, H. S. (2022). Recent studies on stress function-based approaches for the free edge stress analysis of smart composite laminates: a brief review. Multiscale Science and Engineering, 4, 73–78.

Luo J, Namburu M, Pattipati K, et al. Model-based prognostic techniques [maintenance applications]. In: Proceedings AUTOTESTCON 2003. IEEE Systems Readiness Technology Conference. Ieee, 2003, pp. 330–340.

Schwabacher M. A survey of data-driven prognostics. In: Infotech@ Aerospace. 2005, p. 7002.

Roh, H. D., Lee, H., & Park, Y.-B. (2016). Structural health monitoring of carbon-material-reinforced polymers using electrical resistance measurement. International Journal of Precision Engineering and Manufacturing-Green Technology, 3, 311–321.

Khan, A., Shin, J. K., Lim, W. C., et al. (2020). A deep learning framework for vibration-based assessment of delamination in smart composite laminates. Sensors, 20, 2335.

Daigle, M. J., & Goebel, K. (2011). A model-based prognostics approach applied to pneumatic valves. International Journal Progn Health Manag, 2, 84–99.

Khan, A., & Kim, H. S. (2022). Classification and prediction of multidamages in smart composite laminates using discriminant analysis. Mechanics of Advanced Materials and Structures, 29, 230–240.

Khan, A., Hwang, H., & Kim, H. S. (2021). Synthetic data augmentation and deep learning for the fault diagnosis of rotating machines. Mathematics, 9, 2336.

Svinth, C. N., Wallace, S., Stephenson, D. B., et al. (2022). Identifying Abnormal CFRP Holes Using Both Unsupervised and Supervised Learning Techniques on In-Process Force, Current, and Vibration Signals. International Journal of Precision Engineering and Manufacturing, 23, 609–625.

Tsui, K. L., Chen, N., Zhou, Q., et al. (2015). Prognostics and health management: A review on data driven approaches. Mathematical Problems in Engineering. https://doi.org/10.1155/2015/793161

Guépié BK, Lecoeuche S. Similarity-based residual useful life prediction for partially unknown cycle varying degradation. In: 2015 IEEE Conference on Prognostics and Health Management (PHM). IEEE, 2015, pp. 1–7.

Atamuradov, V., Medjaher, K., Dersin, P., et al. (2017). Prognostics and health management for maintenance practitioners-review, implementation and tools evaluation. Int J Progn Health Manag, 8, 1–31.

Chu, C.-H., Lee, C.-J., & Yeh, H.-Y. (2020). Developing Deep Survival Model for Remaining Useful Life Estimation Based on Convolutional and Long Short-Term Memory Neural Networks. Wireless Communications and Mobile Computing. https://doi.org/10.1155/2020/8814658

Nguyen, D. V., Kefalas, M., Yang, K., et al. (2019). A review: Prognostics and health management in automotive and aerospace. Int J Progn Health Manag, 10, 35.

Zhang, L., Lin, J., Liu, B., et al. (2019). A review on deep learning applications in prognostics and health management. Ieee Access, 7, 162415–162438.

Khan, A., Kim, J.-S., & Kim, H. S. (2021). Damage Detection and Isolation from Limited Experimental Data Using Simple Simulations and Knowledge Transfer. Mathematics, 10, 80.

Kim, S. W., Kong, J. H., Lee, S. W., et al. (2022). Recent advances of artificial intelligence in manufacturing industrial sectors: a review. International Journal of Precision Engineering and Manufacturing, 23, 111–129.

Kim, D.-H., Ryu, C.-H., Park, S.-H., et al. (2017). Nondestructive evaluation of hidden damages in glass fiber reinforced plastic by using the terahertz spectroscopy. Int J Precis Eng Manuf-Green Technol, 4, 211–219.

Si, X.-S., Wang, W., Hu, C.-H., et al. (2011). Remaining useful life estimation–a review on the statistical data driven approaches. European Journal of Operational Research, 213, 1–14.

Medjaher, K., & Zerhouni, N. (2013). Hybrid prognostic method applied to mechatronic systems. International Journal of Advanced Manufacturing Technology, 69, 823–834.

Baraldi, P., Cadini, F., Mangili, F., et al. (2013). Model-based and data-driven prognostics under different available information. Probabilistic Eng Mech, 32, 66–79.

Kim N-H, An D, Choi J-H.2017 Prognostics and health management of engineering systems. Switz Springer Int Publ.

Song, S., Xiong, C., Zheng, J., et al. (2021). Compression, bending, energy absorption properties, and failure modes of composite Kagome honeycomb sandwich structure reinforced by PMI foams. Composite Structures, 277, 114611.

Nam, S., Lee, D. K., Jeong, Y.-K., et al. (2016). Environmental impact assessment of composite small craft manufacturing using the generic work breakdown structure. Int J Precis Eng Manuf-Green Technol, 3, 261–272.

Greenhalgh E, Hiley M. Fractography of polymer composites: current status and future issues.

Singh, R. K., & Chennamsetti, R. (2014). Propagation of Ao mode through the front edge of a delamination: Numerical and experimental studies. International Journal of Precision Engineering and Manufacturing, 15, 1639–1645.

Xu, L. R., & Rosakis, A. J. (2002). Impact failure characteristics in sandwich structures: Part I: Basic failure mode selection. International Journal of Solids and Structures, 39, 4215–4235.

Luo HA, Chen Y. Matrix cracking in fiber-reinforced composite materials.

McCarthy, C., & Vaughan, T. (2015). Micromechanical failure analysis of advanced composite materials. Numerical Modelling of Failure in Advanced Composite Materials (pp. 379–409). Amsterdam: Elsevier.

Rebière, J.-L. (2014). Matrix cracking and delamination evolution in composite cross-ply laminates. Cogent Eng, 1, 943547.

Groves, S. E., Harris, C. E., Highsmith, A. L., et al. (1987). An experimental and analytical treatment of matrix cracking in cross-ply laminates. Experimental Mechanics, 27, 73–79.

Cantwell, W. J. (2007). Geometrical effects in the low velocity impact response of GFRP. Composites Science and Technology, 67, 1900–1908.

Cantwell, W. J., & Morton, J. (1992). The significance of damage and defects and their detection in composite materials: A review. Journal of Strain Analysis for Engineering Design, 27, 29–42.

Corbetta, M., Sbarufatti, C., Giglio, M., et al. (2018). A Bayesian framework for fatigue life prediction of composite laminates under co-existing matrix cracks and delamination. Composite Structures, 187, 58–70.

Liu, X., Wang, B., Ai, F., et al. (2020). Evaluation of matrix cracking in composite laminates based on anomaly indices. International Journal of Fatigue, 140, 105841.

Graham-Jones, J., & Summerscales, J. (2015). Marine applications of advanced fibre-reinforced composites. Cambridge: Woodhead Publishing.

Talreja, R., & Varna, J. (2015). Modeling damage, fatigue and failure of composite materials. Amsterdam: Elsevier.

Vitale, J. P., Francucci, G., Xiong, J., et al. (2017). Failure mode maps of natural and synthetic fiber reinforced composite sandwich panels. Compos Part Appl Sci Manuf, 94, 217–225.

Khan, R. (2019). Fiber bridging in composite laminates: a literature review. Composite Structures, 229, 111418.

Das, A. K., Suthar, D., & Leung, C. K. (2019). Machine learning based crack mode classification from unlabeled acoustic emission waveform features. Cement and Concrete Research, 121, 42–57.

Li, Y., Reese, S., & Simon, J.-W. (2018). Modeling the fiber bridging effect in cracked wood and paperboard using a cohesive zone model. Engineering Fracture Mechanics, 196, 83–97.

Saeedifar, M., Fotouhi, M., Najafabadi, M. A., et al. (2016). Prediction of quasi-static delamination onset and growth in laminated composites by acoustic emission. Composites. Part B, Engineering, 85, 113–122.

Greenhalgh, E. (2009). Failure analysis and fractography of polymer composites. Amsterdam: Elsevier.

Khan, A., Khalid, S., Raouf, I., et al. (2021). Autonomous assessment of delamination using scarce raw structural vibration and transfer learning. Sensors, 21, 6239.

Khan, A., Raouf, I., Noh, Y. R., et al. (2022). Autonomous assessment of delamination in laminated composites using deep learning and data augmentation. Composite Structures, 290, 115502.

Chittala, T. S., Burela, R. G., & Ponnusami, S. A. (2021). Delamination Detection and Localization in Laminated Structures Using Machine Learning Techniques. Advances in Interdisciplinary Engineering (pp. 215–225). Singapore: Springer.

Jacobs, E. W., Yang, C., Demir, K. G., et al. (2020). Vibrational detection of delamination in composites using a combined finite element analysis and machine learning approach. Journal of Applied Physics, 128, 125104.

Khan, A., Ko, D.-K., Lim, S. C., et al. (2019). Structural vibration-based classification and prediction of delamination in smart composite laminates using deep learning neural network. Composites. Part B, Engineering, 161, 586–594.

Daneshjoo, Z., Shokrieh, M. M., & Fakoor, M. (2018). A micromechanical model for prediction of mixed mode I/II delamination of laminated composites considering fiber bridging effects. Theoretical and Applied Fracture Mechanics, 94, 46–56.

Longbiao, L. (2017). Modeling first matrix cracking stress of fiber-reinforced ceramic-matrix composites considering fiber fracture. Theoretical and Applied Fracture Mechanics, 92, 24–32.

Kazemi, M. E., Shanmugam, L., Lu, D., et al. (2019). Mechanical properties and failure modes of hybrid fiber reinforced polymer composites with a novel liquid thermoplastic resin, Elium®. Compos Part Appl Sci Manuf, 125, 105523.

Ejaz, M., Azad, M. M., Shah, A. U. R., et al. (2020). Mechanical and Biodegradable Properties of Jute/Flax Reinforced PLA Composites. Fibers Polym, 21, 2635–2641.

Huang, B.-T., Li, Q.-H., Xu, S.-L., et al. (2018). Fatigue deformation behavior and fiber failure mechanism of ultra-high toughness cementitious composites in compression. Materials and Design, 157, 457–468.

Reifsnider, K. L. (2012). Fatigue of composite materials. Amsterdam: Elsevier.

Tao, C., Ji, H., Qiu, J., et al. (2017). Characterization of fatigue damages in composite laminates using Lamb wave velocity and prediction of residual life. Composite Structures, 166, 219–228.

Highsmith AL, Reifsnider KL. 1982 Stiffness-reduction mechanisms in composite laminates. In: Damage in composite materials: basic mechanisms accumulation tolerance and characterization. ASTM International, Conshohocken

Highsmith AL, Reifsnider KL. Damage in composite materials: basic mechanisms, accumulation, tolerance, and characterization. ASTM Int.

Garrett, K. W., & Bailey, J. E. (1977). Multiple transverse fracture in 90 cross-ply laminates of a glass fibre-reinforced polyester. Journal of Materials Science, 12, 157–168.

Joffe, R., & Varna, J. (1999). Analytical modeling of stiffness reduction in symmetric and balanced laminates due to cracks in 90 layers. Composites Science and Technology, 59, 1641–1652.

Schulte K. 1985 Stiffness reduction and development of longitudinal cracks during fatigue loading of composite laminates. Mech Characterisation Load Bear Fibre Compos Laminates; 36–54.

Schulte K, Baron C, Neubert H, et al. DAMAGE DEVELOPMENT IN CARBON FIBRE EPOXY LAMINATES: CYCLIC LOADING.

Schulte K. Fatigue Behaviour and Damage Development in Woven Fabric and Hybrid Fabric Composites, 1987. ICCM VI; 489–499.

Nairn, J. A., & Hu, S. (1992). The initiation and growth of delaminations induced by matrix microcracks in laminated composites. International Journal of Fracture, 57, 1–24.

O’Brien, T. K. (1985). Analysis of Local Delaminations and Their Influence on Composite Laminate Behavior. Delamination Debonding Mater. https://doi.org/10.1520/STP36310S

Kelly, A., & Zweben, C. H. (2000). Comprehensive composite materials. Amsterdam: Elsevier.

Lee, L. J., Fu, K. E., & Yang, J. N. (1996). Prediction of fatigue damage and life for composite laminates under service loading spectra. Composites Science and Technology, 56, 635–648.

Huang, J., Pastor, M.-L., Garnier, C., et al. (2019). A new model for fatigue life prediction based on infrared thermography and degradation process for CFRP composite laminates. International Journal of Fatigue, 120, 87–95.

Li, X., Kupski, J., De Freitas, S. T., et al. (2020). Unfolding the early fatigue damage process for CFRP cross-ply laminates. International Journal of Fatigue, 140, 105820.

Elenchezhian MRP. REAL-TIME MATERIAL STATE ASSESSMENT OF COMPOSITES USING ARTIFICIAL IN℡LIGENCE AND ITS CHALLENGES. PhD Thesis, 2021.

Orifici, A. C., Thomson, R. S., Degenhardt, R., et al. (2009). A finite element methodology for analysing degradation and collapse in postbuckling composite aerospace structures. Journal of Composite Materials, 43, 3239–3263.

Pineda, E. J., & Waas, A. M. (2012). Modelling progressive failure of fibre reinforced laminated composites: mesh objective calculations. Aeronautical Journal, 116, 1221–1246.

PARIS PC. 1961 A rational analytic theory of fatigue. Trend Eng; 13: 9.

Li, S., Sun, L., Jia, W., et al. (1995). The Paris law in metals and ceramics. Journal of Material Science Letters, 14, 1493–1495.

Santecchia, E., Hamouda, A. M. S., Musharavati, F., et al. (2016). A Review on Fatigue life prediction methods for metals. Advances in Materials Science and Engineering, 2016, e9573524.

Yao, L., Sun, Y., Guo, L., et al. (2018). A validation of a modified Paris relation for fatigue delamination growth in unidirectional composite laminates. Composites. Part B, Engineering, 132, 97–106.

Raimondo, A., Doesburg, S. A., & Bisagni, C. (2020). Numerical study of quasi-static and fatigue delamination growth in a post-buckled composite stiffened panel. Composites. Part B, Engineering, 182, 107589.

Asp, L. E., Sjögren, A., & Greenhalgh, E. S. (2001). Delamination growth and thresholds in a carbon/epoxy composite under fatigue loading. Journal of Composites Technology and Research, 23, 55–68.

Schön, J. (2000). A model of fatigue delamination in composites. Composites Science and Technology, 60, 553–558.

Li, Y., Kurfess, T. R., & Liang, S. Y. (2000). Stochastic prognostics for rolling element bearingS. Mechanical Systems and Signal Processing, 14, 747–762.

Li, Y., Billington, S., Zhang, C., et al. (1999). Adaptive prognostics for rolling element bearing condition. Mechanical Systems and Signal Processing, 13, 103–113.

Peel L. Data driven prognostics using a Kalman filter ensemble of neural network models. In: 2008 International Conference on Prognostics and Health Management. 2008, pp. 1–6.

Melgar, M., Gomez-Jimenez, C., Cot, L. D., et al. (2016). Paris law parameter identification based on the extended Kalman Filter. MATEC Web Conf, 83, 03003.

Wang, Y., Binaud, N., Gogu, C., et al. (2016). Determination of Paris’ law constants and crack length evolution via Extended and Unscented Kalman filter: An application to aircraft fuselage panels. Mechanical Systems and Signal Processing, 80, 262–281.

Corbetta M, Sbarufatti C, Manes A, et al. Sequential Monte Carlo sampling for crack growth prediction providing for several uncertainties. PHM Soc Eur Conf; 2. Epub ahead of print 2014. DOI: https://doi.org/10.36001/phme.2014.v2i1.1475.

Saha, B., Goebel, K., & Christophersen, J. (2009). Comparison of prognostic algorithms for estimating remaining useful life of batteries. Transactions of the Institute of Measurement and Control, 31, 293–308.

Pascoe, J. A., Alderliesten, R. C., & Benedictus, R. (2013). Methods for the prediction of fatigue delamination growth in composites and adhesive bonds – a critical review. Engineering Fracture Mechanics, 112–113, 72–96.

Bak, B. L. V., Sarrado, C., Turon, A., et al. (2014). Delamination Under Fatigue Loads in Composite Laminates: A Review on the Observed Phenomenology and Computational Methods. Applied Mechanics Reviews. https://doi.org/10.1115/1.4027647

Chiachío, J., Chiachío, M., Saxena, A., et al. (2015). Bayesian model selection and parameter estimation for fatigue damage progression models in composites. International Journal of Fatigue, 70, 361–373.

Chiach ́ıo J, Chiach ́ıo M, Saxena A, et al. 2013 An Energy-Based Prognostic Framework to Predict Fatigue Damage Evolution in Composites. Annu Conf PHM Soc. https://doi.org/10.36001/phmconf.2013.v5i1.2273.

Peng, T., Liu, Y., Saxena, A., et al. (2015). In-situ fatigue life prognosis for composite laminates based on stiffness degradation. Composite Structures, 132, 155–165.

Rabiei E, Lopez Droguett E, Modarres M. Damage monitoring and prognostics in composites via dynamic Bayesian networks. In: 2017 Annual Reliability and Maintainability Symposium (RAMS). 2017, pp. 1–7.

Banerjee, P., Karpenko, O., Udpa, L., et al. (2018). Prediction of impact-damage growth in GFRP plates using particle filtering algorithm. Composite Structures, 194, 527–536.

Pugalenthi, K., Trung Duong, P. L., Doh, J., et al. (2021). Online prognosis of bimodal crack evolution for fatigue life prediction of composite laminates using particle filters. Applied Sciences, 11, 6046.

Daneshjoo, Z., Shokrieh, M. M., Fakoor, M., et al. (2018). A new mixed mode I/II failure criterion for laminated composites considering fracture process zone. Theoretical and Applied Fracture Mechanics, 98, 48–58.

Pascoe, J. A., Alderliesten, R. C., & Benedictus, R. (2015). On the relationship between disbond growth and the release of strain energy. Engineering Fracture Mechanics, 133, 1–13.

Jones, R., Stelzer, S., & Brunner, A. J. (2014). Mode I, II and Mixed Mode I/II delamination growth in composites. Composite Structures, 110, 317–324.

Andersons, J., Hojo, M., & Ochiai, S. (2004). Empirical model for stress ratio effect on fatigue delamination growth rate in composite laminates. International Journal of Fatigue, 26, 597–604.

Ramkumar RL. Performance of a Quantitative Study of Instability-Related Delamination Growth. NORTHROP CORP HAWTHORNE CA AIRCRAFT DIV, https://apps.dtic.mil/sti/citations/ADA305939 (1 March 1983, accessed 6 October 2021).

Robinson, E. I., Marzat, J., & Raïssi, T. (2018). Filtering and uncertainty propagation methods for model-based prognosis of fatigue crack growth in unidirectional fiber-reinforced composites. ASCE-ASME J Risk Uncertain Eng Syst Part Civ Eng, 4, 04018040.

Adden, S., & Horst, P. (2010). Stiffness degradation under fatigue in multiaxially loaded non-crimped-fabrics. International Journal of Fatigue, 32, 108–122.

Anyfantis, K. N., & Tsouvalis, N. G. (2012). Post buckling progressive failure analysis of composite laminated stiffened panels. Applied Composite Materials, 19, 219–236.

Kashtalyan, M., & Soutis, C. (2016). Modelling of stiffness degradation due to cracking in laminates subjected to multi-axial loading. Philos Trans R Soc Math Phys Eng Sci, 374, 20160017.

Barbero, E. J. (2007). Finite Element Analysis of Composite Materials. CRC Press.

Führer, T. (2017). Stiffness degradation of composite skin fields due to strength and buckling onset. Thin-Walled Struct, 119, 522–530.

Abir, M. R., Tay, T. E., Ridha, M., et al. (2017). Modelling damage growth in composites subjected to impact and compression after impact. Composite Structures, 168, 13–25.

Hashin, Z. (1980). Failure criteria for unidirectional fiber composites. Journal of Applied Mechanics, 47, 329–334.

Puck, A., & Schürmann, H. (2004). Chapter 5.6 - Failure analysis of FRP laminates by means of physically based phenomenological models. In M. J. Hinton, A. S. Kaddour, & P. D. Soden (Eds.), Failure Criteria in Fibre-Reinforced-Polymer Composites (pp. 832–876). Oxford: Elsevier.

Lopez, R. H., Luersen, M. A., & Cursi, E. S. (2009). Optimization of laminated composites considering different failure criteria. Composites. Part B, Engineering, 40, 731–740.

Reddy, J. N. (2003). Mechanics of Laminated Composite Plates and Shells: Theory and Analysis (2nd ed.). Rome: CRC Press.

Lee, M. S., Seo, H. Y., & Kang, C. G. (2016). Comparative study on mechanical properties of CR340/CFRP composites through three point bending test by using theoretical and experimental methods. Int J Precis Eng Manuf-Green Technol, 3, 359–365.

Zhao, L., Qin, T., Zhang, J., et al. (2013). Modified maximum stress failure criterion for composite π joints. Journal of Composite Materials, 47, 2995–3008.

Lee, C.-S., Kim, J.-H., Kim, S., et al. (2015). Initial and progressive failure analyses for composite laminates using Puck failure criterion and damage-coupled finite element method. Composite Structures, 121, 406–419.

Benzeggagh, M. L., & Kenane, M. (1996). Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Composites Science and Technology, 56, 439–449.

Yetman, J. E., Sobey, A. J., Blake, J. I. R., et al. (2015). Investigation into skin stiffener debonding of top-hat stiffened composite structures. Composite Structures, 132, 1168–1181.

Liu, P. F., & Zheng, J. Y. (2010). Recent developments on damage modeling and finite element analysis for composite laminates: a review. Materials and Design, 31, 3825–3834.

Tay, T. E., Liu, G., Tan, V. B. C., et al. (2008). Progressive failure analysis of composites. Journal of Composite Materials, 42, 1921–1966.

Liu, P. F., & Zheng, J. Y. (2008). Progressive failure analysis of carbon fiber/epoxy composite laminates using continuum damage mechanics. Materials Science and Engineering A, 485, 711–717.

Maimi, P., Mayugo, J. A., & Camanho pp. (2008). A Three-dimensional damage model for transversely isotropic composite laminates. Journal of Composite Materials., 42, 2717–2745.

Ubaid, J., Kashfuddoja, M., & Ramji, M. (2014). Strength prediction and progressive failure analysis of carbon fiber reinforced polymer laminate with multiple interacting holes involving three dimensional finite element analysis and digital image correlation. International Journal of Damage Mechanics, 23, 609–635.

Zhang, B. M., & Zhao, L. (2012). Progressive damage and failure modeling in fiber-reinforced laminated composites containing a hole. International Journal of Damage Mechanics, 21, 893–911.

Shabani, P., Taheri-Behrooz, F., Maleki, S., et al. (2019). Life prediction of a notched composite ring using progressive fatigue damage models. Composites. Part B, Engineering, 165, 754–763.

Li, X., Ma, D., Liu, H., et al. (2019). Assessment of failure criteria and damage evolution methods for composite laminates under low-velocity impact. Composite Structures, 207, 727–739.

Wang, K., Zhao, L., Hong, H., et al. (2018). A strain-rate-dependent damage model for evaluating the low velocity impact induced damage of composite laminates. Composite Structures, 201, 995–1003.

Xu, J., & El Mansori, M. (2016). Numerical modeling of stacked composite CFRP/Ti machining under different cutting sequence strategies. International Journal of Precision Engineering and Manufacturing, 17, 99–107.

Hosseini-Toudeshky, H., Goodarzi, M. S., & Mohammadi, B. (2013). Prediction of through the width delamination growth in post-buckled laminates under fatigue loading using de-cohesive law. Structural Engineering and Mechanics, 48, 41–56.

Hosseini-Toudeshky, H., Jahanmardi, M., & Goodarzi, M. S. (2015). Progressive debonding analysis of composite blade root joint of wind turbines under fatigue loading. Composite Structures, 120, 417–427.

Naderi, M., & Iyyer, N. (2020). Micromechanical analysis of damage mechanisms under tension of 0°–90° thin-ply composite laminates. Composite Structures, 234, 111659.

Yang, Y., Liu, X., Wang, Y.-Q., et al. (2017). A progressive damage model for predicting damage evolution of laminated composites subjected to three-point bending. Composites Science and Technology, 151, 85–93.

Jalalvand, M., Wisnom, M. R., Hosseini-Toudeshky, H., et al. (2014). Experimental and numerical study of oblique transverse cracking in cross-ply laminates under tension. Compos Part Appl Sci Manuf, 67, 140–148.

Mahmoud, B., Manseri, L., Rogani, A., et al. (2019). Experimental and numerical study of the damage mechanisms in hybrid unidirectional/woven composites under impact loading. Composite Structures, 209, 606–615.

Wang, C. (2020). Transverse crack evolution modeling of cross-ply laminates with a single layer of phantom node intraply elements for identically-oriented ply groups. Composite Structures, 254, 112842.

Meng, M., Le, H. R., Rizvi, M. J., et al. (2015). 3D FEA modelling of laminated composites in bending and their failure mechanisms. Composite Structures, 119, 693–708.

Im, J.-M., Kang, S.-G., Shin, K.-B., et al. (2017). Prediction of onset and propagation of damage in the adhesive joining of a dome-separated composite pressure vessel including temperature effects. International Journal of Precision Engineering and Manufacturing, 18, 1795–1804.

Akhavan-Safar, A., Monteiro, J., Carbas, R., et al. (2020). Tensile fatigue life prediction of adhesively bonded structures based on CZM technique and a modified degradation approach. Proc Inst Mech Eng Part G J Aerosp Eng, 234, 1988–1999.

Acknowledgements

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF-2020R1A2C1006613), funded by the Ministry of Education, and also supported by the Ministry of Trade, Industry, and Energy (MOTIE) and the Korea Institute for Advancement of Technology (KIAT), through the International Cooperative R&D program (Project No. P0011923 and P0016173), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khan, A., Azad, M.M., Sohail, M. et al. A Review of Physics-based Models in Prognostics and Health Management of Laminated Composite Structures. Int. J. of Precis. Eng. and Manuf.-Green Tech. 10, 1615–1635 (2023). https://doi.org/10.1007/s40684-023-00509-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-023-00509-4