Abstract

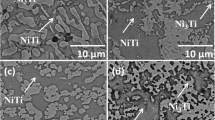

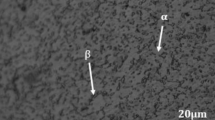

Nickel-rich (54–56 at.% Ni) NiTi-based alloys have gained increased attention for their high hardness, corrosion resistance, strength, and wear resistance, leading to their development for high-performance bearings and other wear applications. An investigation of a broader compositional range of NiTiHf alloys, in terms of Ni and Hf content, is presented in this study. Their Vickers micro-hardness, 3 ball-on-rod rolling contact fatigue, and compression performances are benchmarked against early compositions identified for bearing applications, e.g., Ni55Ti45 and Ni54Ti45Hf1. The results show that by varying heat treatments and alloy composition, certain NiTiHf alloys can exhibit long life (~ 107 cycles) at 10–20% greater contact stress levels (up to 2.2–2.4 GPa), together with up to 20% greater hardness (up to 770 HV) and 30% larger compressive yield strengths (up to 3.4 GPa) than the original bearing compositions. These improvements are attributed to the ability to develop alloys with high-volume fractions of fine precipitate phases. Interestingly, a variety of combinations of different precipitate strengthening phases, depending on alloy composition and heat treatment, were able to achieve improvements relative to Ni55Ti45 and Ni54Ti45Hf1, demonstrating the versatility of the NiTiHf system.

Similar content being viewed by others

References

DellaCorte C, Stanford MK, Jett TR (2015) Rolling contact fatigue of superelastic intermetallic materials (SIM) for use as resilient corrosion resistant bearings. Tribol Lett 57:1–10

DellaCorte C, Wozniak WA (2012) Design and manufacturing considerations for shockproof and corrosion-immune superelastic Nickel-Titanium bearings for a space station application. NASA/TM-2012-216015

DellaCorte C, Noebe RD, Stanford MK, Padula S (2012) Resilient and corrosion-proof rolling element bearings made from superelastic Ni-Ti alloys for aerospace mechanism applications. In: Takeuchi YR, Mandler WF (eds) Rolling element bearings, STP 1542. West Conshohocken, ASTM International, pp 143–166

DellaCorte C, Pepper S, Noebe R, Hull D, Glennon G (2009) Intermetallic nickel-titanium alloys for oil-lubricated bearing applications. NASA/TM-2009-215646

Clayton P (1993) Tribological behavior of a titanium-nickel alloy. Wear 162:202–210

Abedini M, Ghasemi H, Ahmadabadi MN (2009) Tribological behavior of NiTi alloy in martensitic and austenitic states. Mater Des 30:4493–4497

Buehler WJ (1963) Intermetallic compound based materials for structural applications. In: The Seventh Navy Science Symposium: Solution to Navy Problems through Advanced Technology, 1:1–30

Buehler WJ, Wang FE (1968) A summary of recent research on the Nitinol alloys and their potential application in ocean engineering. Ocean Eng 1:105–120

Ingole S (2013) 60NiTi alloy for tribological and biomedical surface engineering applications. JOM 65:792–798

Stanford MK (2016) Hardness and microstructure of binary and ternary nitinol compounds. NASA/TM-2016-218946

Benafan O, Garg A, Noebe R, Skorpenske H, An K, Schell N (2017) Deformation characteristics of the intermetallic alloy 60NiTi. Intermetallics 82:40–52

Tyber J, McCormick J, Asce SM, Gall K, DesRoches R, Asce M, Maier HJ, Maksoud AEA (2007) Structural engineering with NiTi. I: basic materials characterization. J Eng Mech 133:1009–1018

Hornbuckle BC, Xiao XY, Noebe RD, Martens R, Weaver ML, Thompson GB (2015) Hardening behavior and phase decomposition in very Ni-rich Nitinol alloys. Mater Sci Eng A 639:336–344

Nishida M, Wayman CM, Honma T (1986) Precipitation processes in near-equiatomic TiNi shape memory alloys. Metall Trans A 17:1505–1515

Tirry W, Schryvers D (2005) Quantitative determination of strain fields around Ni4Ti3 precipitates in NiTi. Acta Mater 53:1041–1049

Xu G, Zheng L, Zhang F, Zhang H (2019) Influence of solution heat treatment on the microstructural evolution and mechanical behavior of 60NiTi. J Alloys Compd 775:698–706

Hornbuckle B, Noebe R, Thompson G (2015) Influence of Hf solute additions on the precipitation and hardenability in Ni-rich NiTi alloys. J Alloys Compd 640:449–454

Casalena L, Bucsek AN, Pagan DC, Hommer GM, Bigelow GS, Obstalecki M, Noebe RD, Mills MJ, Stebner AP (2018) Structure-property relationships of a high strength superelastic NiTi–1Hf Alloy. Adv Eng Mater 20:1800046

DellaCorte C, Glennon (2012) Ball bearings comprising nickel-titanium and methods of manufacturing there of Patent No.: US 8,182,741 B1

Stanford MK, Noebe RD, DellaCorte C, Bigelow G, Thomas F (2019) High hardness, high elasticity intermetallic compounds for mechanical components. Patent No.: US 10,364,483 B1

Olver A (2005) The mechanism of rolling contact fatigue: an update. Proc IMechE Part J 219:313–330

Khanlari K, Ramezani M, Kelly P, Cao P, Neitzert T (2018) Comparison of the reciprocating sliding wear of 58Ni39Ti-3Hf alloy and baseline 60NiTi. Wear 408:120–130

Khanlari K, Ramezani M, Kelly P, Cao P, Neitzert T (2018) Reciprocating sliding wear behavior of 60NiTi as compared to 440C steel under lubricated and unlubricated conditions. Tribol Trans 61:991–1002

Amin-Ahmadi B, Pauza JG, Shamimi A, Duerig TW, Noebe RD, Stebner AP (2018) Coherency strains of H-phase precipitates and their influence on functional properties of nickel-titanium-hafnium shape memory alloys. Scr Mater 147:83–87

Bigelow GS, Garg A, Padula SA, Gaydosh DJ, Noebe RD (2011) Load-biased shape-memory and superelastic properties of a precipitation strengthened high-temperature Ni50.3Ti29.7Hf20 alloy. Scr Mater 64:725–728

Santamarta R, Arroyave R, Pons J, Evirgen A, Karaman I, Karaca HE, Noebe RD (2013) TEM study of structural and microstructural characteristics of a precipitate phase in Ni-rich Ni–Ti–Hf and Ni–Ti–Zr shape memory alloys. Acta Mater 61:6191–6206

Yang F, Coughlin DR, Phillips PJ, Yang L, Devaraj A, Kovarik L, Noebe RD, Mills MJ (2013) Structure analysis of a precipitate phase in an Ni-rich high-temperature NiTiHf shape memory alloy. Acta Mater 61:3335–3346

Specification for 60Ni-40Ti Billets. (2016) MSFC-SPEC-3706, Marshall Space Flight Center, Alabama

Menezes PL, Nosonovsky M, Ingole SP, Kailas SV, Lovell MR (eds) (2013) Tribology for scientists and engineers. Springer, New York

Ringsberg JW (2001) Life prediction of rolling contact fatigue crack initiation. Int J Fatigue 23:575–586

Amin-Ahmadi B, Gallmeyer T, Pauza JG, Duerig TW, Noebe RD, Stebner AP (2018) Effect of a pre-aging treatment on the mechanical behaviors of Ni50.3Ti49.7-xHfx (x ≤ 9 at.%) shape memory alloys. Scr Mater 147:11–15

Han X, Zou W, Wang R, Jin S, Zhang Z, Li T, Yang D (1997) Microstructure of TiNi shape-memory alloy synthesized by explosive shock-wave compression of Ti–Ni powder mixture. J Mater Sci 32:4723–4729

Karlík M, Haušild P, Klementová M, Novák P, Beran P, Perrière L, Kopeček J (2017) TEM phase analysis of NiTi shape memory alloy prepared by self-propagating high-temperature synthesis. Adv Mater Process Technol 3:58–69

Zhang F, Zheng L, Wang F, Zhang H (2018) Effects of Nb additions on the precipitate morphology and hardening behavior of Ni-rich Ni55Ti45 alloys. J Alloys Compd 735:2453–2461

Mills S, Stebner AP, Mills MJ, DellaCorte C, Noebe RD, Amin-Ahmadi B (2020) Characterization of Ni-rich NiTiHf alloys for tribology applications using advanced TEM Techniques. arXiv

Mills S (2019) Development of nickel-titanium-hafnium alloys for impact resistant tribology performances. Ph.D. Dissertation, Colorado School of Mines, Golden, CO

Benafan O, Bigelow GS, Garg A, Noebe RD (2019) Viable low temperature shape memory alloys based on Ni-Ti-Hf formulations. Scr Mater 164:115–120

Armstrong PJ, Frederick C (1966) A mathematical representation of the multiaxial Bauschinger effect. CEGB Report No. RD/B/N731, Central Electricity Generating Board. Reproduced (2007) Mater High Temp 24:21–26

Yoshida F, Uemori T (2002) A model of large-strain cyclic plasticity describing the Bauschinger effect and workhardening stagnation. Int J Plast 18:661–686

Tirry W, Schryvers D (2004) High resolution TEM study of Ni4Ti3 precipitates in austenitic Ni51Ti49. Mater Sci Eng A 378:157–160

Khalil-Allafi J, Dlouhy A, Eggeler G (2002) Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater 50:4255–4274

Eggeler G, Khalil-Allafi J, Gollerthan S, Somsen C, Schmahl W, Sheptyakov D (2005) On the effect of aging on martensitic transformations in Ni-rich NiTi shape memory alloys. Smart Mater Struct 14:S186–S191

Frenzel J, Wieczorek A, Opahle I, Maaβ B, Drautz R, Eggeler G (2015) On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater 90:213–231

Benafan O, Bigelow G, Scheiman D (2018) Transformation behavior in NiTi-20Hf shape memory alloys: transformation temperatures and hardness. Scr Mater 146:251–254

Hertz H (1882) On the contact of rigid elastic solids and on hardness. Reprinted from Assorted papers by H. Hertz, Chap 6, MacMillan pp. 163–183.

Antoine J-F, Visa C, Sauvey C, Abba G (2006) Approximate analytical model for Hertzian elliptical contact problems. J Tribol 128:660–664

Acknowledgements

This work was conducted within the National Science Foundation (NSF) I/UCRC Center for Advanced Non-Ferrous Structural Alloys (CANFSA), which is a joint industry–university center between the Colorado School of Mines and Iowa State University. Additional financial support was provided for this work through the NASA Transformative Aeronautics Concepts Program (TACP), Transformational Tools & Technologies Project under the guidance of Dr. Othmane Benafan, technical lead for shape memory alloys. Dr. Benafan is also thanked for providing the Ni55Ti45 compression data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special issue of Shape Memory and Superelasticity to honor Prof. Dr.-Ing. Gunther Eggeler. This special issue was organized by Prof. Hüseyin Sehitoglu, University of Illinois at Urbana-Champaign, and Prof. Dr.-Ing. Hans Jürgen Maier, Leibniz Universität Hannover.

Rights and permissions

About this article

Cite this article

Mills, S.H., Noebe, R.D., Dellacorte, C. et al. Development of Nickel-Rich Nickel–Titanium–Hafnium Alloys for Tribological Applications. Shap. Mem. Superelasticity 6, 311–322 (2020). https://doi.org/10.1007/s40830-020-00296-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-020-00296-w