Abstract

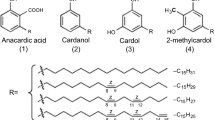

Environmental concerns about coating material have led manufacturers towards considering bio-based alternatives to conventional petroleum–derived epoxy resins. Considering these concerns with rise in prices and high depletion of petroleum resources, a viable alternative polymer resin has been synthesized from characteristic cashew nut shell liquid (CNSL). In this study, cardanol, a major component of cashew nut shell liquid, was used to synthesize cardanol-based vinyl ester resole (CBVER) and cardanol-based vinyl ester novolac (CBVEN) resins. The vinyl ester resins synthesized were characterized using international standard methods. The molecular weight of the resins was determined to be 1069 and 1001 g/mol for CBVER and CBVEN, respectively, using gas chromatographic mass spectroscopy (GCMS). Fourier transform infrared (FTIR) and thermogravimetric (TGA) analysis were used to identify the functional groups and analyze the material weight changes with stability relative to temperature. FTIR results revealed functional groups typical of thermosetting resin. The results of the mechanical and thermal properties of the resins showed improved performance and material’s thermal stability (up to a temperature of 280 °C), respectively. The chemical resistance properties of the cardanol-based vinyl ester resins showed improved performance when subjected to solvent, alkalis, and acids, an indication of anti-corrosive properties. The better performances of cardanol-based vinyl ester resins obtained from this study is justifiable and suggest applicability in coatings, for both anticorrosion and interior/exterior decorations.

Similar content being viewed by others

References

N.V. Sadavarte, Difunctional monomers starting from cashew nut shell liquid (CNSL) and high-performance polymers therefrom. Doctoral dissertation, University of Pune, India (2012)

M.B. Gawande, V.D.B. Bonifácio, R. Luque, P.S. Branco, R.S. Varma, Solvent free and catalysts-free chemistry: a benign pathway to sustainability. Chem. Sus. Chem. 7, 24–44 (2014)

P. Anastas, N. Eghbali, Green chemistry: principles and practice. Chem. Soc. Rev. 39, 301–312 (2010)

K.P. Unnikrishnan, E.T. Thachil, Synthesis and characterization of cardanol-based epoxy systems. Des. Monomers Polym. 11, 593–607 (2008)

R.C. Cioc, E. Ruijter, R.V.A. Orru, Multicomponent reactions: advanced tools for sustainable organic synthesis. Green Chem. 16, 2958–2975 (2014)

C.C. Ugoamadi, Comparison of cashew nut shell liquid (CNS) resin with polyester resin in composite development. Niger. J. Technol. Dev. 10(2), 17–21 (2013)

A. Zlatanic, Z.S. Petrovic, K. Dusek, Structure and properties of triolein-based polyurethane networks. Biomacromol 3, 1048–1056 (2003)

S. Gopalakrishnan, N.T. Nevaditha, C.V. Mythili, Synthesis and characterization of bifunctional monomers for high performance polymers from renewable resource. Int. J. Chem. Technol. Res. 4(1), 48–54 (2012)

R. Yadav, D. Srivastava, Blends of cardanol based epoxidised novolac resins and CTBN for applications in surface coatings. J. Coat. Technol. Res. 7(5), 557–568 (2010)

X. Li, L.G. Tabil, S. Panigrahi, Chemical treatments of natural fibre for use in natural fibre reinforced composites; A Review. J. Polym. Environ. 15, 25–33 (2007)

D. D’Amico, L. Longo, C. Stifani, A. Tarzia, Cardanol-based novolac resins as curing agents of epoxy resins Pietro Campaner. J. Appl. Polym. Sci. 114(1), 3585–3591 (2009)

S.K. Kyei, O. Akaranta, G. Darko, U.J. Chukwu, Extraction, characterization and application of cashew but shell liquid from cashew but shells. Chem. Sci. Int. J. 28(3), 1–10 (2019)

S. Mohapatra, G.B. Nando, Cardanol: a green substitute for aromatic oil as a plasticizer in natural rubber. Royal Soc. Chem. Adv. 4, 15406–15418 (2014)

M. Yuliana, B.T. Nguyen-Thi, S. Faika, L.H. Huynh, F.E. Soetaredjo, Ju. Yi-Hsu, Separation and purification of cardol, cardanol and anacardic acid from cashew (Anacardium occidentale L.) nut-shell liquid using a simple two-step column chromatography. J. Taiwan Inst. Chem. Eng. 45, 2187–2193 (2014)

R. Ikeda, H. Tanaka, H. Uyama, S. Kobayashi. Synthesis and curing behaviors of a crosslinkable polymer from cashew nut shell liquid. Polymer. 43(12), 3845-3481 (2002)

S. Kanehashi, K. Yokoyama, R. Masuda, T. Kidesaki, K. Nagai, T. Miyakoshi, Preparation and characterization of cardanol-based epoxy resin for coating at room temperature curing. J. Appl. Polym. Sci. 2468–2478 (2013). https://doi.org/10.1002/app.39382

J.-H. Lee, J. Jeon, S. Kim, Green adhesives using tannin and cashew nut shell liquid for environment-friendly furniture materials. J. Korea Furnit. Soc. 22(3), 219–229 (2011)

V. Kathir, F. Emerson, A process for selective extraction of cardanol from cashew nut shell liquid (CNSL) and its useful applications Solomon. Int. J. Sci. Eng. Res. 4(3), 1–4 (2013)

C. Voirin, S. Caillol, N.V. Sadavarte, B.V. Tawade, B. Boutevinab, P.P. Wadgaonkar, Functionalization of cardanol: towards biobased polymers and additives. Polym. Chem. 5, 3142 (2014)

R. Paramashiyappa, P. Phani Kumar, J. Vithayathil, A. Srinivasa Rao, Novel method for isolation of major phenolic constituents from Cashew (Anacardium occidentale L) nut shell Liquid. J. Agric. Food Chem. 49, 2548–2551 (2001)

A. Devi, D. Srivatsava, Studies on the blends of cardanol- based epoxidised nonolac resin and CTPB. Eur. Polymer J. 43(6), 2422–2432 (2007)

FAOSTAT, Food and Agriculture Organization of the United Nations Data. Statistical Databases. (2012). http://faostat.fao.org/default.aspx?lang=en. Accessed 11/01/2022

C.K.S. Pillai, V.S. Prasad, J.D. Sudha, S.C. Bera, A.R.R. Menon, J. Appl. Polym. Sci. 41, 2487 (1990)

A.R.R. Menon, C.K.S. Pillai, G.B. Nando, J. Adhes. Sci. Technol. 9, 443 (1995)

M. Saminathan, C.K.S. Pillai, C. Krishn, C. Pavithran, Macromolecules 26, 7103 (1993)

C.K.S. Pillai, D.C. Sherrington, A. Sneddon, Polym. Commun. 33(18), 3968–3970 (1992)

R. Yadav, D. Srivastava. Material chemistry and physics. 1(15), 74-81 (2007)

L.K. Aggarwal, P.C. Thapliyal, S.R. Karade, Anticorrosive properties of the epoxy cardanol, based paints. Prog. Org. Coat. 59(1), 76–80 (2007)

K. Yamada, H. Yamane, K. Kumada, S. Tanabe, T. Kajiyama, Plasma-graft polymerization of a monomer with double bonds onto the surface of carbon fiber and its adhesion to a vinyl ester resin. J. Appl. Polym. Sci. 90, 2415–2419 (2003)

B.F, Howell, De. Realf. Pigmented coatings cured with visible light, Polym. Mater. Sci. Eng. 74, 387–38 (1996)

S. Masujiro, J. Kazuyoshi, Thermosetting printing ink. JP 74(67), 709 (1974)

M. Henne, C. Breyer, M. Niedermeir, P.A. Ermanni, New kinetics and viscosity model for liquid composite molding simulations in an industrial environment. Polym. Compos. 25, 255–269 (2004)

P. Rahmawati, A.H. Ramelan, S.D. Marliyana, N.S. Suharty, S. Wahyuningsih, Synthesis of cardanol-based novolac resin from cashew nut shell liquid. J. Eng. Sci. 15, 23–33 (2019)

S.K. Shukla, K. Srivastava, D. Srivastava, Studies on the thermal, mechanical and chemical resistance properties of natural resource derived polymers. Mater. Res. 18(6), 1217–1223 (2015). https://doi.org/10.1590/1516-1439.007715

M. Sultania, J.S.P. Rai, D. Srivastava, Studies on the synthesis and curing of epoxidized novolac vinyl ester resin from renewable resource material. Eur Polym J 46, 2019–2032 (2010)

S. Rwahwire, B. Tomkova, A.P. Periyasamy and B.M. Kale (2019). Green thermoset reinforced biocomposites. Green composites for automotive applications. Chapter 3, 61–80 (2019). https://doi.org/10.1016/B978-0-08-102177-4.00003-3

B. Lochab, S. Shukla, I.K. Varma, Naturally occurring phenolic sources: Monomers and polymers. RSC Adv. 4(42), 21712–21752 (2014). https://doi.org/10.1039/c4ra00181h

N. Zora, T. Rigaux, J.C. Buvat, D. Lefebvre, S. Leveneur, Influence assessment of inlet parameters on thermal risk and productivity: application to the epoxidation of vegetable oils. J. Loss Prev. Process Ind. 72, 104551 (2021)

U.P. Laverdura, L. Rossi, F. Ferella, C. Courson, A. Zarli, R. Alhajyoussef, K. Gallucci, Selective catalytic hydrogenation of vegetable oils on lindlar catalyst. Asc Omega 5, 22901–22913 (2020)

S. Soares, F.R.P. Rocha, Multi-energy calibration to circumvent matrix effects in the determination of biodiesel quality parameters by UV-Vis spectrophotometry. Talanta 209, 120584 (2020)

V.B. Borugadda, V.V. Goud, Hydroxylation and hexanoylation of epoxidized waste cooking oil and epoxidized waste cooking oil methyl esters: Process optimization and physico-chemical characterization. Ind. Crop. Prod. 133, 151–159 (2019)

Y. Su, S. Zhang, Y. Chen, T. Yuan, Z. Yang, One-step synthesis of novel renewable multi-functional linseed oil-based acrylate prepolymers and its application in UV-curable coatings. Prog. Org. Coat. 148, 105820 (2020)

F. Dominici, M.D. Samper, A. Carbonell-Verdu, F. Luzi, J. López-Martínez, L. Torre, D. Puglia, Improved toughness in lignin/natural fiber composites plasticized with epoxidized and maleinized linseed oils. Materials 13, 600 (2020)

Z. Zhou, J.P.D. Abbatt, Formation of gas-phase hydrogen peroxide via multiphase ozonolysisi of unsaturated lipids. Environ. Sci. Technol. Lett. 8, 114–120 (2021)

P.M. Paraskar, R.D. Kulkarni, Synthesis of isostearic acid/dimer fatty acid-based polyesteramide polyol for the development of green polyurethane coatings. J. Polym. Environ. 29, 54–70 (2021)

W.R. Slama. Polyester and vinyl ester coatings. Journal of Protective Coatings & Linings. 88–109 (1996)

F.W. Njuku, P.M. Nwangi, G.T. Thiongo, Evaluation of cashew nut liquid based products as a reactive diluents for alkyd coatings. Int. J. Adv. Res. 2(3), 5–10 (2014)

J. Zhu, S. Wei, J. Ryu, M. Budhathoki, G. Liangd, Z. Guo, In situ stabilized carbon nanofiber (CNF) reinforced epoxy nanocomposites. J. Mater. Chem. 20, 4937–494 (2010). https://doi.org/10.1039/c0jm00063a

L. Preeti, N. Anil, Thermal and mechanical properties of environment-friendly ‘green’ plastics from stearic acid modified-soy protein isolate. Ind. Crop. Prod. 21(1), 49–64 (2005). https://doi.org/10.1016/j.indcrop.2003.12.006

M.M. Rahman, A.N. Netravali, B.J. Tiimob, V.K. Rangari, Bioderived green composite from soy protein and eggshell nanopowder. ACS Sustain. Chem. Eng. 2, 2329–2337 (2014)

B.J. Tiimob, S. Jeelani, V.K. Rangari, Eggshell reinforced biocomposite – an advanced “green” alternative structural material. J. Appl. Polym. Sci. 133, 1–10 (2016). https://doi.org/10.1002/app.43124

C. Wang, Q. Sun, K. Lei, C. Chen, L. Yao, Z. Peng, Effect of toughening with different liquid rubber on dielectric relaxation properties of epoxy resin. Polymers 12, 433 (2020). https://doi.org/10.3390/polym12020433

K.S.M. Barczewski, R. Gorny, A. Klozinski, Evaluation of highly filled epoxy composites modified with walnut shell waste filler. Polymer Bullerin 75, 2511–2528 (2018). https://doi.org/10.1007/s00289-017-2163-3

S. Ma, W. Liu, N. Gao, Z. Yan, Y. Zhao, Synthesis and properties of LED-packaging epoxy resin toughened by a novel polysiloxane from hydrolysis and condensation. Macromol. Res. 19(9), 972–979 (2011). https://doi.org/10.1007/s13233-0110911-z

X. Jing, H. Mi, B. Napiwocki, X. Peng, L. Turng, Mussel-inspired electroactive chitosan/graphene oxide composite hydrogel with rapid self-healing and recovery behavior for tissue engineering. Carbon 125, 557–570 (2017). https://doi.org/10.1016/j.carbon.2017.09.071

M. Shibata, Y. Itakura, H. Watanabe, Bio-based thermosetting resins composed of cardanol novolac and bismaleimide. Polym. J. 45, 758–765 (2013)

E. Kinaci, E. Can, J.J. LaScala, G.R. Palmese, Influence of epoxidized cardanol functionality and reactivity on network formation and properties. Polymers 12, 1956 (2020). https://doi.org/10.3390/polym12091956

Xi. Zhang, V. Bitaraf, S. Wei, Z. Guo, Vinyl ester resin: rheological behaviors, curing kinetics, thermomechanical, and tensile properties. Am. Inst. Chem. Eng. (2013). https://doi.org/10.1002/aic.14277266-274

F. Yeasmin, A.K. Mallik, A.H. Chisty, F.N. Robel, Md. Shahruzzaman, P. Haque, M. Mizanur Rahman, N. Hano, M. Takafuji, H. Ihara. Remarkable enhancement of thermal stability of epoxy resin through the incorporation of mesoporous silica micro-filler Heliyon, 7(1), e05959 (2021). https://doi.org/10.1016/j.heliyon.2021.e05959

S.A. Kolawole, S.A. Danladi, U.S. Ishiaku, B.M. Dauda, Thermogravimetry analysis of epoxy and unsaturated polyester filled with some agricultural waste of dates palm (Phoenix dactylifera) and African Elemi (Canarium shweinfurthii) particulate composites. J. Mater. Sci. Res. Rev. 3(4), 1–9 (2019)

K. Strzelec, Studies on the properties of epoxy resins cured with polythiourethanes. Int. J. Adhes. Adhes. 27(2), 9–101 (2007)

A.J. Farhan, Characterization the thermal degradation E kinetic of unsaturated polyester and polyester/silica nanoparticles composites by TGA and DSC analysis. J Adv. Res. Fluid Mech. Thermal Sci. 71(1), 10–20 (2020)

F. Jaillet, H. Nouailhas, R. Auvergne, A. Ratsimihety, B. Boutevin, S. Caillol. Synthesis and characterization of novel vinylester prepolymers from cardanol. Eur. J. Lipid Sci. Technol. 116, 928–939 (2014). https://doi.org/10.1002/ejlt.201300487

M.S Garga, K. Srivastavab, D. Srivastava. Physical and chemical toughening of cardanol-based vinyl ester resin using CTBN: A study on spectral, thermal and morphological characteristics. Prog. Org. Coat. 78, 307–317 (2014). https://doi.org/10.1016/j.porgcoat.2014.08.004

J.S. Terry, A.C. Taylor, The properties and suitability of commercial bio-based epoxies for use in fiber-reinforced composites. J. Appl. Polym. Sci. 138, e50417 (2021). https://doi.org/10.1002/app.50417

F. Wang, J. Liao, C. Huang, H. Yu, J. Yan, H. Li, Study on the damping dynamics characteristics of a viscoelastic damping material. Processes 10, 635 (2022). https://doi.org/10.3390/pr10040635

B. Herzog, D.J. Gardner, R. Lopez-Anido, B. Goodell, Glass transition temperature based on dynamic mechanical thermal analysis techniques as an indicator of the adhesive performance of vinyl ester resin. J. Appl. Polym. Sci. 97, 2221–2229 (2005)

M. Kathalewar, A. Sabnis, Epoxy resin from cardanol as partial replacement of bisphenol A-based epoxy for coating application J. Coat. Technol. Res. 11, 601–618 (2014). https://doi.org/10.1007/s11998-014-9570-2

M. Pourbaix, Atlas of electrochemical equilibria in aqueous solution, 2nd edn. (NACE, Houston, 1974)

Acknowledgements

The authors acknowledge Project-200 of Prof. Charles Esimone, Vice Chancellor, Nnamdi Azikiwe University, Awka, Anambra State, Nigeria.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Nwuzor, I.C., Okolie, P.C., Ezeani, O.E. et al. Production of epoxidized cardanol–based vinyl ester resins with cinnamic acid for eco-friendly coating materials. emergent mater. 5, 2061–2074 (2022). https://doi.org/10.1007/s42247-022-00396-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-022-00396-6