Abstract

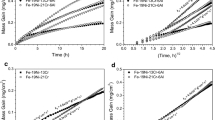

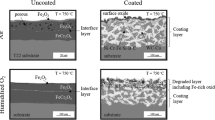

The high-temperature corrosion behavior of Fe-30.1Mn-9.7Al-0.77C alloy initially coated with 2 mg/cm2 NaCl/Na2SO4 (100/0, 75/25, 50/50, 25/75 and 0/100 wt.%) deposits has been studied at 750°C in air. The result shows that weight-gain kinetics in simple oxidation reveals a steady-state parabolic rate law after 3 hr, while the kinetics with salt deposits all display multi-stage growth rates. The corrosion morphology of the alloy with 100% Na2SO4 coating is similar to that of simple oxidation. NaCl acts as the predominant corrosion species for Fe-Mn-Al-C alloy, inhibiting the formation of a protective oxide scale. For the alloy coated with over 50% NaCl in salts, NaCl induces selective oxidation of manganese and results in the formation of secondary ferrite in the alloy substrate as well as void-layers with different densities of voids layer by layer in the secondary-ferrite zone.

Similar content being viewed by others

References

G. Y. Lai, in High-Temperature Corrosion of Engineering Alloys, American Society for Metals Metals Park, OH, 1990, p. 117.

Y. Bourhis and C. St. John, Oxid. Met. 9, 507(1975).

Y. Niu, F. Gesmundo, F. Viani, and W. Wu, Oxid. Met. 42, 265(1994).

D. M. Johnson, D. P. Whittle, and J. Stringer, Corr. Sci. 15, 721(1975).

R. Wang, M. J. Straszheim, and R. A. Rapp, Oxid. Met. 21, 71(1984).

S. K. Banerji, An Update on Fe-Mn-Al Steels, Proceedings of the Workshop on “Conservation and Substitution Technology for Critical Materials”, Vanderbilt University, Nashville, Tennessee, June 1981.

S. C. Tjong, Mater. Techno. 60, 91(1989).

C. J. Wang and Y. C. Chang, Mater. Chem. Phys. 76, 151(2002).

C. J. Wang and Y. C. Chang, Oxid. Met. 57, 363(2002).

C. J. Wang and Y. C. Chang, Oxid. Met. 59, 135(2003).

C. J. Wang and Y. C. Chang, Mater. Chem. Phys. 77, 738(2002).

K. Hossain and S. R. J. Saunders, Oxid. Met. 12, 1(1978).

Y. Shinata, Oxid. Met. 27, 315(1987).

V. Buscaglia, P. Nanni, and C. Bottino, Corr. Sci. 30, 327(1990).

A. Holt and P. Kofstad, Mater. Sci. Eng. A120, 101(1989).

M. A. Clevinger, K. M. Kessell, C. G. Messina, and H. M. Ondik (Eds.), Phase Diagrams for Ceramists, The American Ceramic Society, Inc., OH, 1989, Fig. 7109.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, CJ., Chang, YC. & Su, YH. The Hot Corrosion of Fe-Mn-Al–C Alloy with NaCl/Na2SO4 Coating Mixtures at 750°C. Oxidation of Metals 59, 115–133 (2003). https://doi.org/10.1023/A:1023022100300

Issue Date:

DOI: https://doi.org/10.1023/A:1023022100300