Abstract

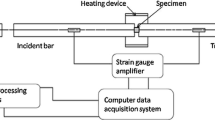

Dynamic equal-channel angular pressing, a new method for the intense plastic deformation of materials, was developed and applied to titanium, as an example. A sample, accelerated in a gun to a velocity of 300 m/s, impinged on a matrix with intesecting channels. The deformation of titanium occurred at a shear-deformation rate of 104–105 s−1 and pressure of several GPa. Upon deformation, the strength of titanium increased by a factor of 2, with the plasticity remaining at an acceptable level. Metallographic and electron microscopy analyses demonstrated that, under the action of intense deformation, the initial course-grained structure of titanium transforms into an ultrafine-grained one.

Similar content being viewed by others

References

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials: Obtaining Intense Plastic Deformation (Logos, Moscow, 2000) [in Russian].

V. M. Segal, V. I. Reznikov, and A. E. Drobyshevskii, Izv. Akad. Nauk SSSR, Met., No. 1, 115 (1981).

E. V. Shorokhov, I. N. Zhgilev, and R. Z. Valiev, RF Patent No. 2283717, Byull. Izobret., No. 26 (2006).

Author information

Authors and Affiliations

Additional information

Original Russian Text © E.V. Shorokhov, I.N. Zhgilev, D.V. Gunderov, A.A. Gurov, 2008, published in Khimicheskaya Fizika, 2008, Vol. 27, No. 3, pp. 77–80.

Rights and permissions

About this article

Cite this article

Shorokhov, E.V., Zhgilev, I.N., Gunderov, D.V. et al. Dynamic pressing of titanium for producing an ultrafine-grained structure. Russ. J. Phys. Chem. B 2, 251–254 (2008). https://doi.org/10.1134/S1990793108020139

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1990793108020139