Abstract

Freeze-drying is a relatively expensive process requiring long processing time, and hence one of the key objectives during freeze-drying process development is to minimize the primary drying time, which is the longest of the three steps in freeze-drying. However, increasing the shelf temperature into secondary drying before all of the ice is removed from the product will likely cause collapse or eutectic melt. Thus, from product quality as well as process economics standpoint, it is very critical to detect the end of primary drying. Experiments were conducted with 5% mannitol and 5% sucrose as model systems. The apparent end point of primary drying was determined by comparative pressure measurement (i.e., Pirani vs. MKS Baratron), dew point, Lyotrack (gas plasma spectroscopy), water concentration from tunable diode laser absorption spectroscopy, condenser pressure, pressure rise test (manometric temperature measurement or variations of this method), and product thermocouples. Vials were pulled out from the drying chamber using a sample thief during late primary and early secondary drying to determine percent residual moisture either gravimetrically or by Karl Fischer, and the cake structure was determined visually for melt-back, collapse, and retention of cake structure at the apparent end point of primary drying (i.e., onset, midpoint, and offset). By far, the Pirani is the best choice of the methods tested for evaluation of the end point of primary drying. Also, it is a batch technique, which is cheap, steam sterilizable, and easy to install without requiring any modification to the existing dryer.

Similar content being viewed by others

Notes

The starting material used in these studies contained ∼20% degradation, more than normal for fresh material, apparently due to degradation during storage.

Previous results suggest that methionine oxidation in hGH is accelerated by free radical oxidation in the drying chamber (15).

It may be that the deterioration of the gauge depends to some extent on the gauge construction. However, it is important to note that at least one readily available gauge is relatively robust. Also, since it is very easy to “calibrate” the Pirani during each run (i.e., early in primary drying the gauge should read 60% higher than the differential capacitance manometer), one can easily compensate for some loss of performance due to whatever cause.

References

Pikal MJ. Freeze-drying of proteins: process, formulation, and stability. ACS Symposium Series. 1994;567:120–33. Formulation and Delivery of Proteins and Peptides.

Adams GDJ, Irons LI. Some implications of structural collapse during freeze-drying using Erwinia caratovora l-asparaginase as a model. J Chem Biotechnol. 1993;58:71–6.

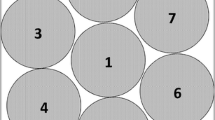

Rambhatla S, Pikal MJ. Heat and mass transfer scale-up issues during freeze-drying, I: atypical radiation and the edge vial effect. AAPS PharmSciTech. 2003;4(2):111–20.

Pikal MJ, Roy ML, Shah S. Mass and heat transfer in vial freeze-drying of pharmaceuticals: role of the vial. J Pharm Sci. 1984;73(9):1224–37.

Nail SL, Johnson W. Methodology for in-process determination of residual water in freeze-dried products. Dev Biol Stand. 1992;74:137–51. Biol. Prod. Freeze-Drying Formulation.

Roy ML, Pikal MJ. Process control in freeze drying: determination of the end point of sublimation drying by an electronic moisture sensor. J Parenter Sci Technol. 1989;43(2):60–6.

Gieseler H, Kessler WJ, Finson M, Davis SJ, Mulhall PA, Bons V, et al. Evaluation of tunable diode laser absorption spectroscopy for in-process water vapor mass flux measurements during freeze drying. J Pharm Sci. 2007;96(7):1776–93.

Mayeresse YVR, Sibille PH, Nomine C. Freeze-drying process monitoring using a cold plasma ionization device. PDA J Pharm Sci Technol. 2007;61(3).

Bardat A, Biguet J, Chatenet E, Courteille F. Moisture measurement: a new method for monitoring freeze-drying cycles. J Parenter Sci Technol. 1993;47(6):293–9.

Tang X, Pikal MJ. Design of freeze-drying processes for pharmaceuticals: practical advice. Pharm Res. 2004;21(2):191–200.

Tang X, Nail SL, Pikal MJ. Freeze-drying process design by manometric temperature measurement: design of a smart freeze-dryer. Pharm Res. 2005;22(4):685–700.

Pikal MJ, Dellerman KM, Roy ML, Riggin RM. The effects of formulation variables on the stability of freeze-dried human growth hormone. Pharm Res. 1991;8(4):427–36.

Riggin RM, Dorulla GK, Miner DJ. A reversed-phase high-performance liquid chromatographic method for characterization of biosynthetic human growth hormone. Anal Biochem. 1987;167(1):199–209.

Milton N, Pikal MJ, Roy ML, Nail SL. Evaluation of manometric temperature measurement as a method of monitoring product temperature during lyophilization. PDA J Pharm Sci Tech. 1997;51(1):7–16.

Pikal MJ, Roy ML. Unpublished observations.

Patel SM, Jameel F, Pikal MJ. Effect of dryer load on freeze-drying process design. AAPS Annual Meeting. San Antonio, Texas, USA; 2006.

Hatley RHM, Mant A. Determination of the unfrozen water content of maximally freeze-concentrated carbohydrate solutions. Int J Biol Macromol. 1993;15(4):227–32.

Zasypkin DV, Lee T-C. Extracellular ice nucleators from pantoea ananas: effects on freezing of model foods. J Food Sci. 1999;64(3):473–8.

Acknowledgments

The authors would like to acknowledge Pfizer, Inc. for partly funding this project. Also, we thank Alcatel vacuum technologies for providing Lyotrack and Physical Sciences Inc. for providing TDLAS for evaluation in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patel, S.M., Doen, T. & Pikal, M.J. Determination of End Point of Primary Drying in Freeze-Drying Process Control. AAPS PharmSciTech 11, 73–84 (2010). https://doi.org/10.1208/s12249-009-9362-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-009-9362-7