Abstract

Nanoindentation is an integral technique in determining material properties at small length scales. The indentation size effect (ISE) manifests as increasing hardness as indent depths become shallower. This makes material comparison across length scales challenging. The objective of this work is to study how load function parameters influence hardness, especially at shallow depths where the ISE is most critical. Hardness values from indentation loading methods with different hold and cycling sequences were compared from tests on four pure metal samples. Results show a significant decrease in hardness after both long hold and repeated loading profiles. The decrease was larger at shallow depths, and materials with a lower hardness were found to have a larger percent decrease than harder materials. We discuss these observations in the context of Cottrell’s exhaustion creep and recommend that indentation load functions with hold periods or repeated loading be used to minimize observed ISE.

Graphical abstract

Similar content being viewed by others

Availability of data and material

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

A.L. Romasco, L.H. Friedman, L. Fang, R.A. Meirom, T.E. Clark, R.G. Polcawich, J.S. Pulskamp, M. Dubey, C.L. Muhlstein, Deformation behavior of nanograined platinum films. Thin Solid Films 518(14), 3866 (2010)

G. Molino, A. Dalpozzi, G. Ciapetti, M. Lorusso, C. Novara, M. Cavallo, N. Baldini, F. Giorgis, S. Fiorilli, C. Vitale-Brovarone, Osteoporosis-related variations of trabecular bone properties of proximal human humeral heads at different scale lengths. J. Mech. Behav. Biomed. Mater. 100, 103373 (2019)

J. Yeager, K. Ramos, S. Singh, M. Rutherford, J. Majewski, D. Hooks, Nanoindentation of explosive polymer composites to simulate deformation and failure. Mater. Sci. Technol. 28, 1147 (2012)

P. Trtik, B. Münch, P. Lura, A critical examination of statistical nanoindentation on model materials and hardened cement pastes based on virtual experiments. Cement Concr. Compos. 31(10), 705 (2009)

V. Zanjani Zadeh, C.P. Bobko, Nano-mechanical properties of internally cured kenaf fiber reinforced concrete using nanoindentation. Cem Concr Composites 52(2), 9 (2014)

J.L. Cuy, A.B. Mann, K.J. Livi, M.F. Teaford, T.P. Weihs, Nanoindentation mapping of the mechanical properties of human molar tooth enamel. Arch. Oral Biol. 47(4), 281 (2002)

C.M. McCarter, R.F. Richards, S.D. Mesarovic, C.D. Richards, D.F. Bahr, D. McClain, J. Jiao, Mechanical compliance of photolithographically defined vertically aligned carbon nanotube turf. J. Mater. Sci. 41(23), 7872 (2006)

D. Chrobak, R. Nowak, Nanoindentation of semiconductors: experiment and atomistic simulations. J. Phys. Conf. Ser. 281, 2028 (2011)

M. Vanlandingham, J. Villarrubia, W. Guthrie, G. Meyers, Nanoindentation of polymers: an overview. Macromol. Symposia 167 (2001)

M.K. Mishra, G.R. Desiraju, U. Ramamurty, A.D. Bond, Studying microstructure in molecular crystals with nanoindentation: intergrowth polymorphism in Felodipine. Angew. Chem. Int. Ed. 53(48), 13102 (2014)

J. B. Pethica: in Ion Implantation into Metals, edited by V. Ashworth, W. Grant, and R. Procter (Pergamon, 1982), pp. 147–156.

C.K. Dolph, D.J. da Silva, M.J. Swenson, J.P. Wharry, Plastic zone size for nanoindentation of irradiated Fe–9%Cr ODS. J. Nucl. Mater. 481, 33 (2016)

M. Vincent, Q. Tong, N. Terziev, G. Daniel, C. Bustos, W.G. Escobar, I. Duchesne, A comparison of nanoindentation cell wall hardness and Brinell wood hardness in jack pine (Pinus banksiana Lamb.). Wood Sci. Technol. 48(1), 7 (2014)

P.M. Sargent, Indentation size effect and strain-hardening. J. Mater. Sci. Lett. 8(10), 1139 (1989)

M. Atkinson, Origin of the size effect in indentation of metals. Int. J. Mech. Sci. 33(10), 843 (1991)

W.D. Nix, H. Gao, Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46(3), 411 (1998)

A.A. Elmustafa, D.S. Stone, Indentation size effect in polycrystalline FCC metals. Acta Mater. 50(14), 3641 (2002)

W.W. Gerberich, N.I. Tymiak, J.C. Grunlan, M.F. Horstemeyer, M.I. Baskes, Interpretations of indentation size effects. J. Appl. Mech. 69(4), 433 (2002)

A.A. Elmustafa, D.S. Stone, Stacking fault energy and dynamic recovery: do they impact the indentation size effect? Mater. Sci. Eng. A 358(1–2), 1 (2003)

H. Li, The Nanoindentation Size Effects of Creep, The University of Hong Kong (Pokfulam, Hong Kong, 2004)

Y. Huang, F. Zhang, K. Hwang, W. Nix, G. Pharr, G. Feng, A model of size effects in nano-indentation. J. Mech. Phys. Solids 54(8), 1668 (2006)

K. Durst, O. Franke, A. Böhner, M. Göken, Indentation size effect in Ni–Fe solid solutions. Acta Mater. 55(20), 6825 (2007)

K. Durst, M. Göken, G.M. Pharr, Indentation size effect in spherical and pyramidal indentations. J. Phys. D 41(7), 074005 (2008)

D.E. Stegall, Md.A. Mamun, B. Crawford, A. Elmustafa, Indentation size effect in FCC metals: an examination of experimental techniques and the bilinear behavior. J. Mater. Res. 27(12), 1543 (2012)

S.-W. Lee, L. Meza, J.R. Greer, Cryogenic nanoindentation size effect in [0 0 1]-oriented face-centered cubic and body-centered cubic single crystals. Appl. Phys. Lett. 103(10), 101906 (2013)

A.A. Elmustafa, D.S. Stone, Nanoindentation and the indentation size effect: kinetics of deformation and strain gradient plasticity. J. Mech. Phys. Solids 51(2), 357 (2003)

G.M. Pharr, E.G. Herbert, Y. Gao, The indentation size effect: a critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40(1), 271 (2010)

K. Sangwal, Review: indentation size effect, indentation cracks and microhardness measurement of brittle crystalline solids - some basic concepts and trends. Cryst. Res. Technol. 44(10), 1019 (2009)

G. Voyiadjis, M. Yaghoobi, Review of nanoindentation size effect: experiments and atomistic simulation. Curr. Comput. Aided Drug Des. 7(10), 321 (2017)

N.A. Fleck, G.M. Muller, M.F. Ashby, J.W. Hutchinson, Strain gradient plasticity: theory and experiment. Acta Metall. Mater. 42(2), 475 (1994)

J.B. Pethica, D. Tabor, Contact of characterised metal surfaces at very low loads: deformation and adhesion. Surf. Sci. 89(1), 182 (1979)

H. Li, A. Ghosh, Y.H. Han, R.C. Bradt, The frictional component of the indentation size effect in low load microhardness testing. J. Mater. Res. 8(5), 1028 (1993)

V. Maier, C. Schunk, M. Göken, K. Durst, Microstructure-dependent deformation behaviour of bcc-metals—indentation size effect and strain rate sensitivity. Philos. Mag. 95(16–18), 1766 (2015)

J. Zhao, F. Wang, P. Huang, T.J. Lu, K.W. Xu, Depth dependent strain rate sensitivity and inverse indentation size effect of hardness in body-centered cubic nanocrystalline metals. Mater. Sci. Eng. A 615, 87 (2014)

X. Ma, F. Li, Z. Sun, J. Hou, J. Li, X. Fang, Strain rate dependence of the indentation size effect in Ti–10V–2Fe–3Al alloy. Mater. Sci. Technol. 35(9), 1107 (2019)

D. Chicot, E.S. Puchi-Cabrera, A. Iost, M.H. Staia, X. Decoopman, F. Roudet, G. Louis, Analysis of indentation size effect in copper and its alloys. Mater. Sci. Technol. 29(7), 868 (2013)

J.E. Jakes, Improved methods for nanoindentation Berkovich probe calibrations using fused silica. J Mater Sci 53(7), 4814 (2018)

O. Franke, J.C. Trenkle, C.A. Schuh, Temperature dependence of the indentation size effect. J. Mater. Res. 25(07), 1225 (2010)

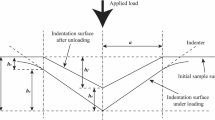

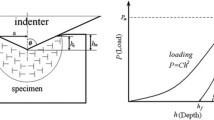

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(06), 1564 (1992)

S. A. Asif and J. B. Pethica: in MRS Proceedings (Cambridge Univ Press, 1996), p. 201.

B.N. Lucas, W.C. Oliver, G.M. Pharr, J.-L. Loubet, Time dependent deformation during indentation testing. MRS Proc. 436, 23–238 (1996)

A.C. Fischer-Cripps, A simple phenomenological approach to nanoindentation creep. Mater. Sci. Eng. A 385(1–2), 74 (2004)

A.H. Cottrell, The time laws of creep. J. Mech. Phys. Solids 1(1), 53 (1952)

G.E. Dieter, Mechanical Metallurgy, 2nd edn. (McGraw-Hill, New York, 1976)

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, 1987)

D.F. Bahr, W.W. Gerberich, Plastic zone and pileup around large indentations. Metall. Mater. Trans. A 27(12), 3793 (1996)

Y. Gaillard, C. Tromas, J. Woirgard, Quantitative analysis of dislocation pile-ups nucleated during nanoindentation in MgO. Acta Mater. 54(5), 1409 (2006)

S.B. Biner, J.R. Morris, The effects of grain size and dislocation source density on the strengthening behaviour of polycrystals: a two-dimensional discrete dislocation simulation. Null 83(31–34), 3677 (2003)

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Allen, E.M., Moradi, M. & Maughan, M.R. Reducing indentation size effect in metals by load function selection. Journal of Materials Research 36, 2915–2925 (2021). https://doi.org/10.1557/s43578-021-00299-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00299-y