Abstract

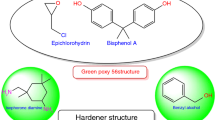

Brittleness is an inherent shortcoming of epoxy resin which results in the longitudinal fatigue cracking of mixtures during the long service time of orthotropic steel deck bridges. In this paper, this problem was addressed by introducing a reactive thermoplastic elastomer, epoxidized styrene–butadiene–styrene copolymer (ESBS) into epoxy asphalt binder (EAB). Epoxy ESBS modified asphalts (EESBAs) with various epoxidation degrees were prepared. Double phase separation occurred in the EESBAs. In the EESBAs with 18% and 31% epoxidation degrees, most of ESBS domains dispersed on the edge of the secondary asphalt phase and in the epoxy phase. Furthermore, the size and number of ESBS domains decreased in the epoxidation degree. However, un-epoxidized SBS domains completely dispersed the asphalt phase and all ESBS domains moved to the epoxy phase when the epoxidation degree increased to 39%. In EESBAs, the average diameters of asphalt domains increased in the epoxidation degree. The inclusion of ESBS increased the viscosity of the pure EAB and the viscosity of EESBAs increased in the epoxidation degree. Nevertheless, all EESBAs had at least a 150-min allowable construction time. By adding 2 wt% ESBS with 39% epoxidation degree, the glass transition temperature (Tg) decreased. The Tg of EESBAs decreased in the epoxidation degree. The inclusion of ESBS greatly enhanced the damping properties of the pure EAB. The elongation at break and toughness of the pure EAB were remarkably increased by 263% and 93%, respectively, with the incorporation of 2 wt% ESBS with 39% epoxidation degree. Furthermore, the toughness of EESBAs increased in the epoxidation degree.

Similar content being viewed by others

References

Yin H, Zhang Y, Sun Y, Xu W, Yu D, Xie H, Cheng R (2015) Performance of hot mix epoxy asphalt binder and its concrete. Mater Struct 48(11):3825–3835. https://doi.org/10.1617/s11527-014-0442-0

Sun Y, Han X, Su W, Gong J, Xi Z, Zhang J, Wang Q, Xie H (2020) Mechanical and bonding properties of pristine montmorillonite reinforced epoxy asphalt bond coats. Polym Compos 41(8):3034–3042. https://doi.org/10.1002/pc.25595

Zhang Y, Pan X, Sun Y, Xu W, Pan Y, Xie H, Cheng R (2014) Flame retardancy, thermal, and mechanical properties of mixed flame retardant modified epoxy asphalt binders. Constr Build Mater 68:62–67. https://doi.org/10.1016/j.conbuildmat.2014.06.028

Si J, Li Y, Wang J, Niyigena AR, Yu X, Jiang R (2020) Improving the compatibility of cold-mixed epoxy asphalt based on the epoxidized soybean oil. Constr Build Mater 243:118235. https://doi.org/10.1016/j.conbuildmat.2020.118235

Zhang H, Gao P, Pan Y, Li K, Zhang Z, Geng F (2020) Development of cold-mix high-toughness resin and experimental research into its performance in a steel deck pavement. Constr Build Mater 235:117427. https://doi.org/10.1016/j.conbuildmat.2019.117427

Medani T, Huurman M, Molenaar AAA (2005) Characterisation of some candidate surfacing materials for orthotropic steel bridge decks. In: Horvli I (ed) Proceedings Seventh International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway

Garg AC, Mai Y-W (1988) Failure mechanisms in toughened epoxy resins—a review. Compos Sci Technol 31(3):179–223. https://doi.org/10.1016/0266-3538(88)90009-7

Zhang Z, Sun J, Huang Z, Wang F, Jia M, Lv W, Ye J (2021) A laboratory study of epoxy/polyurethane modified asphalt binders and mixtures suitable for flexible bridge deck pavement. Constr Build Mater 274:122084. https://doi.org/10.1016/j.conbuildmat.2020.122084

Luo S, Qian ZD Research on low temperature performance of epoxy asphalt mixture. In: Li S, Liu Y, Zhu R, Li H, Ding W (eds) Applied Mechanics and Materials, Switzerland, 2010. Trans Tech Publications, pp 1124–1128

Yin C, Zhang H, Pan Y (2016) Cracking mechanism and repair techniques of epoxy asphalt on steel bridge deck pavement. Transp Res Rec 2550(1):123–130. https://doi.org/10.3141/2550-16

Sun Y, Zhang Y, Xu K, Xu W, Yu D, Zhu L, Xie H, Cheng R (2015) Thermal, mechanical properties, and low-temperature performance of fibrous nanoclay-reinforced epoxy asphalt composites and their concretes. J Appl Polym Sci 132(12):41694. https://doi.org/10.1002/app.41694

Sun Y, Liu Y, Jiang Y, Xu K, Xi Z, Xie H (2018) Thermal and mechanical properties of natural fibrous nanoclay reinforced epoxy asphalt adhesives. Int J Adhes Adhes 85:308–314. https://doi.org/10.1016/j.ijadhadh.2018.07.005

Xue Y, Qian Z (2016) Development and performance evaluation of epoxy asphalt concrete modified with mineral fiber. Constr Build Mater 102:378–383. https://doi.org/10.1016/j.conbuildmat.2015.10.157

Min Z, Wang Q, Xie Y, Xie J, Zhang B (2020) Influence of polyethylene glycol (PEG) chain on the performance of epoxy asphalt binder and mixture. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.121614

Liu Y, Zhang J, Chen R, Cai J, Xi Z, Xie H (2017) Ethylene vinyl acetate copolymer modified epoxy asphalt binders: phase separation evolution and mechanical properties. Constr Build Mater 137:55–65. https://doi.org/10.1016/j.conbuildmat.2017.01.081

Zhang J, Su W, Liu Y, Gong J, Xi Z, Zhang J, Wang Q, Xie H (2021) Laboratory investigation on the microstructure and performance of SBS modified epoxy asphalt binder. Constr Build Mater 270:121378. https://doi.org/10.1016/j.conbuildmat.2020.121378

Jiang Y, Liu Y, Gong J, Li C, Xi Z, Cai J, Xie H (2018) Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater Struct 51(4):86. https://doi.org/10.1617/s11527-018-1217-9

Gong J, Han X, Su W, Xi Z, Cai J, Wang Q, Li J, Xie H (2020) Laboratory evaluation of warm-mix epoxy SBS modified asphalt binders containing Sasobit. J Build Eng 32:101550. https://doi.org/10.1016/j.jobe.2020.101550

Liu Y, Zhang J, Jiang Y, Li C, Xi Z, Cai J, Xie H (2018) Investigation of secondary phase separation and mechanical properties of epoxy SBS-modified asphalts. Constr Build Mater 165:163–172. https://doi.org/10.1016/j.conbuildmat.2018.01.032

Gong J, Liu Y, Jiang Y, Wang Q, Xi Z, Cai J, Xie H (2021) Performance of epoxy asphalt binder containing warm-mix asphalt additive. Int J Pavement Eng 22(2):223–232. https://doi.org/10.1080/10298436.2019.1597272

Liu Y, Xi Z, Cai J, Xie H (2017) Laboratory investigation of the properties of epoxy asphalt rubber (EAR). Mater Struct 50(5):219. https://doi.org/10.1617/s11527-017-1089-4

Su W, Han X, Gong J, Xi Z, Zhang J, Wang Q, Xie H (2020) Toughening epoxy asphalt binder using core-shell rubber nanoparticles. Constr Build Mater 258:119716. https://doi.org/10.1016/j.conbuildmat.2020.119716

Xu P, Zhu X, Cong P, Du X, Zhang R (2018) Modification of alkyl group terminated hyperbranched polyester on paving epoxy asphalt. Constr Build Mater 165:295–302. https://doi.org/10.1016/j.conbuildmat.2017.12.182

Ocando C (2016) Chemically functionalized block copolymers as reactive modifiers for nanostructuring and toughening epoxy thermosetting materials. In: Kortaberria G, Tercjak A (eds) Block copolymer nanocomposites. Pan Stanford Publishing Pte. Ltd., Singapore, pp 173–223

Pandit R, Lach R, Grellmann W, Michler GH, Henning S, Saiter JM, Berkessel A, Adhikari R (2020) Chemical modification of SBS star block copolymer for templating nanostructures in epoxy resin blends. Mater Today Proc 29:1156–1160. https://doi.org/10.1016/j.matpr.2020.05.398

Wu J (2019) Study on epoxidized poly (styrene-butadiene-styrene) modified epoxy resins. University of Akron, Akron

George SM, Puglia D, Kenny JM, Causin V, Parameswaranpillai J, Thomas S (2013) Morphological and mechanical characterization of nanostructured thermosets from epoxy and styrene-block-butadiene-block-styrene triblock copolymer. Ind Eng Chem Res 52(26):9121–9129. https://doi.org/10.1021/ie400813v

Nian F, Ou J, Yong Q, Zhao Y, Pang H, Liao B (2018) Reactive block copolymers for the toughening of epoxies: effect of nanostructured morphology and reactivity. J Macromol Sci Part A 55(7):533–543. https://doi.org/10.1080/10601325.2018.1476826

George SM, Puglia D, Kenny JM, Parameswaranpillai J, Thomas S (2014) Reaction-induced phase separation and thermomechanical properties in epoxidized styrene-block-butadiene-block-styrene triblock copolymer modified epoxy/DDM system. Ind Eng Chem Res 53(17):6941–6950. https://doi.org/10.1021/ie404124b

Venturello C, D’Aloisio R (1988) Quaternary ammonium tetrakis(diperoxotungsto)phosphates(3-) as a new class of catalysts for efficient alkene epoxidation with hydrogen peroxide. J Org Chem 53(7):1553–1557. https://doi.org/10.1021/jo00242a041

Jian X, Hay AS (1991) Catalytic epoxidation of styrene–butadiene triblock copolymer with hydrogen peroxide. J Polym Sci, Part A: Polym Chem 29(8):1183–1189. https://doi.org/10.1002/pola.1991.080290812

Remya VPR, Jose Varghese R, Parani S, Sakho EHM, Oluwafemi OS, Thomas S (2021) Compatibilization of epoxidized triblock copolymer on the generation of self-assembled nanostructured epoxies and their surface wettability. J Appl Polym Sci 138(10):49985. https://doi.org/10.1002/app.49985

Serrano E, Larrañaga M, Remiro PM, Mondragon I, Carrasco PM, Pomposo JA, Mecerreyes D (2004) Synthesis and characterization of epoxidized styrene-butadiene block copolymers as templates for nanostructured thermosets. Macromol Chem Phys 205(7):987–996. https://doi.org/10.1002/macp.200300123

Wang SM, Tsiang RCC (1996) Epoxidation of partially hydrogenated styrene-butadiene block copolymers using peracetic acid in a cyclohexane/water heterogeneous system. J Polym Sci Part A Polym Chem 34(8):1483–1491. https://doi.org/10.1002/(SICI)1099-0518(199606)34:8%3c1483::AID-POLA12%3e3.0.CO;2-4

Zuchowska D (1980) Polybutadiene modified by epoxidation: 1: effect of polybutadiene microstructure on the reactivity of double bonds. Polymer 21(5):514–520. https://doi.org/10.1016/0032-3861(80)90217-7

Pandit R, Giri J, Michler GH, Lach R, Grellmann W, Youssef B, Saiter JM, Adhikari R (2012) Effect of epoxidation of diene component of SBS block copolymer on morphology and mechanical properties. Macromol Symp 315(1):152–159. https://doi.org/10.1002/masy.201250519

Chen R, Zhao R, Liu Y, Cai J, Xi Z, Zhang J, Wang Q, Xie H (2021) Development of eco-friendly fire-retarded warm-mix epoxy asphalt binders using reactive polymeric flame retardants for road tunnel pavements. Constr Build Mater 284:122752. https://doi.org/10.1016/j.conbuildmat.2021.122752

Hsiue G-H, Huang W-K, Hou W-H (1989) Dynamic mechanical and dielectric properties of epoxidized SBS triblock copolymer. J Polym Sci Part A Polym Chem 27(12):4119–4128. https://doi.org/10.1002/pola.1989.080271219

Zhu J, Birgisson B, Kringos N (2014) Polymer modification of bitumen: advances and challenges. Eur Polym J 54:18–38. https://doi.org/10.1016/j.eurpolymj.2014.02.005

Ocando C, Fernández R, Tercjak A, Mondragon I, Eceiza A (2013) Nanostructured thermoplastic elastomers based on sbs triblock copolymer stiffening with low contents of epoxy system. Morphol Behav Mech Prop Macromol 46(9):3444–3451. https://doi.org/10.1021/ma400152g

George SM, Puglia D, Kenny JM, Jyotishkumar P, Thomas S (2012) Cure kinetics and thermal stability of micro and nanostructured thermosetting blends of epoxy resin and epoxidized styrene-block-butadiene-block-styrene triblock copolymer systems. Polym Eng Sci 52(11):2336–2347. https://doi.org/10.1002/pen.23183

Zhang Y, Sun Y, Xu K, Yuan Z, Zhang J, Chen R, Xie H, Cheng R (2015) Brucite modified epoxy mortar binders: flame retardancy, thermal and mechanical characterization. Constr Build Mater 93:1089–1096. https://doi.org/10.1016/j.conbuildmat.2015.05.037

Yin H, Jin H, Wang C, Sun Y, Yuan Z, Xie H, Wang Z, Cheng R (2014) Thermal, damping, and mechanical properties of thermosetting epoxy-modified asphalts. J Therm Anal Calorim 115(2):1073–1080. https://doi.org/10.1007/s10973-013-3449-9

Sun Y, Xu K, Zhang Y, Zhang J, Chen R, Yuan Z, Xie H, Cheng R (2016) Organic montmorillonite reinforced epoxy mortar binders. Constr Build Mater 107:378–384. https://doi.org/10.1016/j.conbuildmat.2016.01.012

Chen R, Gong J, Jiang Y, Wang Q, Xi Z, Xie H (2018) Halogen-free flame retarded cold-mix epoxy asphalt binders: rheological, thermal and mechanical characterization. Constr Build Mater 186:863–870. https://doi.org/10.1016/j.conbuildmat.2018.08.018

Jiang Y, Han X, Gong J, Xi Z, Cai J, Wang Q, Ding G, Xie H (2019) Laboratory investigation of epoxy asphalt binder modified by brominated SBS. Constr Build Mater 228:116733. https://doi.org/10.1016/j.conbuildmat.2019.116733

Esposito LH, Ramos JA, Kortaberria G (2014) Dispersion of carbon nanotubes in nanostructured epoxy systems for coating application. Prog Org Coat 77(9):1452–1458. https://doi.org/10.1016/j.porgcoat.2014.05.001

Li C, Han X, Gong J, Su W, Xi Z, Zhang J, Wang Q, Xie H (2020) Impact of waste cooking oil on the viscosity, microstructure and mechanical performance of warm-mix epoxy asphalt binder. Constr Build Mater 251:118994. https://doi.org/10.1016/j.conbuildmat.2020.118994

Sun Y, Gong J, Liu Y, Jiang Y, Xi Z, Cai J, Xie H (2019) Viscous, damping, and mechanical properties of epoxy asphalt adhesives containing different penetration-grade asphalts. J Appl Polym Sci 136(5):47027. https://doi.org/10.1002/app.47027

Sun Y, Liu Y, Gong J, Han X, Xi Z, Zhang J, Wang Q (2021) Thermal and bonding properties of epoxy asphalt bond coats. J Therm Anal Calorim. https://doi.org/10.1007/s10973-021-10630-8

Chong HM, Taylor AC (2013) The microstructure and fracture performance of styrene–butadiene–methylmethacrylate block copolymer-modified epoxy polymers. J Mater Sci 48(19):6762–6777. https://doi.org/10.1007/s10853-013-7481-8

Masson JF, Bundalo-Perc S, Delgado A (2005) Glass transitions and mixed phases in block SBS. J Polym Sci Part B Polym Phys 43(3):276–279. https://doi.org/10.1002/polb.20319

Hsiue G-H, Yang J-M (1990) Epoxidation of styrene–butadiene–styrene block copolymer and use for gas permeation. J Polym Sci Part A Polym Chem 28(13):3761–3773. https://doi.org/10.1002/pola.1990.080281319

Wang Y, Wei Z, Li Y (2016) Highly toughened polylactide/epoxidized poly(styrene-b-butadiene-b-styrene) blends with excellent tensile performance. Eur Polym J 85:92–104. https://doi.org/10.1016/j.eurpolymj.2016.10.019

Ocando C, Tercjak A, Serrano E, Ramos JA, Corona-Galván S, Parellada MD, Fernández-Berridi MJ, Mondragon I (2008) Micro- and macrophase separation of thermosetting systems modified with epoxidized styrene-block-butadiene- block-styrene linear triblock copolymers and their influence on final mechanical properties. Polym Int 57(12):1333–1342. https://doi.org/10.1002/pi.2478

Wang H, Liu Y, Zhang J, Li T, Hu Z, Yu Y (2015) Effect of curing conversion on the water sorption, corrosion resistance and thermo-mechanical properties of epoxy resin. RSC Adv 5(15):11358–11370. https://doi.org/10.1039/C4RA13678K

Ferry JD (1980) Viscoelastic properties of polymers. John Wiley, New York

Serrano E, Tercjak A, Kortaberria G, Pomposo JA, Mecerreyes D, Zafeiropoulos NE, Stamm M, Mondragon I (2006) Nanostructured thermosetting systems by modification with epoxidized styrene−butadiene star block copolymers. Effect of epoxidation degree. Macromolecules 39(6):2254–2261. https://doi.org/10.1021/ma0515477

Yamanaka K, Inoue T (1989) Structure development in epoxy resin modified with poly(ether sulphone). Polymer 30(4):662–667. https://doi.org/10.1016/0032-3861(89)90151-1

Chang MCO, Thomas DA, Sperling LH (1987) Characterization of the area under loss modulus and tan δ–temperature curves: acrylic polymers and their sequential interpenetrating polymer networks. J Appl Polym Sci 34(1):409–422. https://doi.org/10.1002/app.1987.070340132

Gong J, Liu Y, Wang Q, Xi Z, Cai J, Ding G, Xie H (2019) Performance evaluation of warm mix asphalt additive modified epoxy asphalt rubbers. Constr Build Mater 204:288–295. https://doi.org/10.1016/j.conbuildmat.2019.01.197

Yao S (1994) Means to widen the temperature range of high damping behavior by IPN formation. In: Klempner D, Frisch KC (eds) Advances in interpenetrating polymer networks, vol IV. Technomic Publishing Company. Lancaster, PA, pp 243–286

Han X, Su W, Gong J, Xi Z, Zhang J, Wang Q, Xie H (2021) Microstructure and dynamic mechanical properties epoxy/asphaltene composites. J Therm Anal Calorim. https://doi.org/10.1007/s10973-021-10689-3

Keskkula H, Turley SG, Boyer RF (1971) The significance of the rubber damping peak in rubber-modified polymers. J Appl Polym Sci 15(2):351–367. https://doi.org/10.1002/app.1971.070150209

Xie H, Zhao R, Wang R, Xi Z, Yuan Z, Zhang J, Wang Q (2021) Influence of thermal shock on the performance of B-staged epoxy bond coat for orthotropic steel bridge pavements. Constr Build Mater 294:123598. https://doi.org/10.1016/j.conbuildmat.2021.123598

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jiang, Y., Zhao, R., Xi, Z. et al. Improving toughness of epoxy asphalt binder with reactive epoxidized SBS. Mater Struct 54, 145 (2021). https://doi.org/10.1617/s11527-021-01744-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01744-4