Abstract

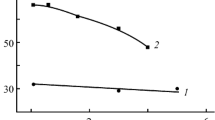

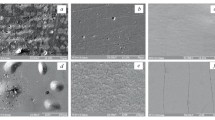

The effect of the electrolyte composition and the stationary electrolysis parameters on the composition and morphology of Fe–Mo and Fe–Co–Mo coatings deposited from complex citrate electrolytes based on Fe(III) is studied. It is shown that, at a constant component ratio of с(Fe3+): с(Co2+): с(MoO2− 4): с(Cit3–) = 2: 2: 1: 4, an increase in the electrolyte concentration leads to a decrease in the pH of the solution in a range of 4.85–4.30 and in the molybdenum content in the coating. An increase in the current density contributes to the molybdenum enrichment of the electrodeposited alloy in the entire range of electrolyte concentrations. The Fe–Mo alloy coatings have a rough microporous surface; an increase in the current density does not lead to significant changes in the surface topography. It is found that the formation of ternary coatings is characterized by the competitive reduction of iron and cobalt in the alloy; the molybdenum content depends on the current density. At a metal ratio of 3: 2: 1 and a molybdenum content of up to 17 at % in the Fe–Co–Mo alloy, the surface has a fine-grained needlelike structure typical of cobalt. With an increase in i c, the atomic fraction of molybdenum increases, while the surface becomes microglobular. The Fe–Co–Mo electrodeposits with a metal ratio of 2.5: 1.5: 1.0 and a molybdenum content of 19–20 at % have a more developed surface with a high density of spheroids.

Similar content being viewed by others

References

Tsyntsaru, N., Cesiulis, H., Donten, M., Sort, J., et al., Surf. Eng. Appl. Electrochem., 2012, vol. 48, no. 6, pp. 491–520.

Podlaha, E.J. and Landolt, D., J. Electrochem. Soc., 1997, vol. 144, no. 5, pp. 1672–1680.

Salvatore, F. and Vasca, E., Ann. Chim., 1990, vol. 80, pp. 515–520.

Protsenko, V. and Danilov, F., Turk. J. Chem., 2015, vol. 39, pp. 610–619. doi 10.3906/kim-1409-61

Kuznetsov, V.V., Golyanin, K.E., and Pshenichkina, T.V., Russ. J. Electrochem., 2012, vol. 48, no. 11, pp. 1107–1112.

Belevskii, S.S., Yushchenko, S.P., and Dikusar, A.I., Surf. Eng. Appl. Electrochem., 2012, vol. 48, no. 1, pp. 97–98.

Podlaha-Murphy, E.J., Silva, M., and Kola, A., NASF Surf. Technol. White Pap., 2014, vol. 78, no. 4, pp. 11–16.

Shul’man, A.I., Belevskii, S.S., Yushchenko, S.P., and Dikusar, A.I., Surf. Eng. Appl. Electrochem., 2014, vol. 50, no. 1, pp. 9–17.

Tsyntsaru, N., Dikusar, A., Cesiulis, H., Celis, J.-P., et al., Powder Metall. Met. Ceram., 2009, vol. 48, nos. 7–8, pp. 419–428.

Karakurkchi, A.V., Ved’, M.V., Sakhnenko, N.D., Yermolenko, I.Yu., et al., Funct. Mater., 2015, vol. 22, no. 2, pp. 181–187. http://dx.doi.org/ 10.15407/fm22.02.181.

Spasojevic, M., Cirovic, N., Ribic-Zelenovic, L., Spasojevic, P., et al., J. Electrochem. Soc., 2014, vol. 161, no. 10, pp. D463–D469. doi 10.1149/2.0041410jes

Karakurkchi, A.V., Ved’, M.V., Sakhnenko, N.D., Yermolenko, I.Yu., et al., Russ. J. Appl. Chem., 2015, vol. 88, no. 11, pp. 1860–1869.

Karakurkchi, A.V., Ved’, M.V., Yermolenko, I.Yu., and Sakhnenko, N.D., Surf. Eng. Appl. Electrochem., 2016, vol. 52, no. 1, pp. 43–49. doi 10.3103/S1068375516010087

Ved’, M.V., Sakhnenko, N.D., Karakurchi, A.V., and Zyubanova, S.I., Russ. J. Appl. Chem., 2014, vol. 87, no. 3, pp. 276–282. doi 10.1134/S1070427214030057

Vukosav, P., Mlakar, M., and Tomisic, V., Anal. Chim. Acta, 2012, vol. 745, no. 1, pp. 85–91.

Ved’, M., Glushkova, M., and Sakhnenko, N., Funct. Mater., 2013, vol. 20, no. 1, pp. 87–91. http://dx.doi.org/10.15407/fm20.01.087.

Ved’, M.V., Sakhnenko, N.D., Karakurkchi, A.V., and Yermolenko, I.Yu., Vopr. Khim. Khim. Tekhnol., 2014, vol. 5, no. 6 (98), pp. 53–60.

Ermolenko, I.Yu., Tekhnol. Audit Rezervy Proizvod., 2014, no. 4-1 (18), pp. 44–48.

Danilov, F.I., Protsenko, V.S., and Ubiikon’, A.V., Russ. J. Electrochem., 2005, vol. 41, no. 12, pp. 1282–1289.

Glushkova, M., Bairachna, T., Ved, M., and Sakhnenko, M., MRS Online Proc. Libr., 2013, vol. 1491. doi 10.1557/opl.2012.1672

Kish, L., Kinetics of Electrochemical Metal Dissolution, Amsterdam: Elsevier, 1988.

Tsyntsaru, N.I., Belevskii, S.S., Volodina, G.F., Bersirova, O.L., Yapontseva, Yu.S., Kublanovskii, V.S., and Dikusar, A.I., Surf. Eng. Appl. Electrochem., 2007, vol. 43, no. 5, pp. 312–317.

Yar-Mukhamedova, G., Ved’, M., Sakhnenko, N., Karakurkchi, A., et al., Appl. Surf. Sci., 2016, vol. 383, pp. 346–352. doi 10.1016/j.apsusc.2016.04.046

Dragos, O., Chiriac, H., Lupu, N., Grigoras, M., et al., J. Electrochem. Soc., 2016, vol. 163, no. 3, pp. D83–D94.

Gong, J., Riemer, S., Morrone, A., Venkatasamy, V., et al., J. Electrochem. Soc., 2012, vol. 159, no. 7, pp. D447–D454. doi 10.1149/2.082207jes

Ghaferi, Z., Sharafi, S., and Bahrololoom, M.E., Appl. Surf. Sci., 2016, vol. 375, no. 1, pp. 35–41. doi 10.1016/j.apsusc.2016.03.063

Yapontseva, Yu.S., Dikusar, A.I., and Kyblanovskii, V.S., Surf. Eng. Appl. Electrochem., 2014, vol. 50, no. 4, pp. 330–336.

Ved’, M., Sakhnenko, N., Bairachnaya, T., and Tkachenko, N., Funct. Mater., 2008, vol. 15, no. 4, pp. 613–617.

He, F.-J., Lei, J.-T., Lu, X., and Huang, Y.-N., Trans. Nonferrous Met. Soc. China, 2004, vol. 14, no. 5, pp. 901–906.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.V. Ved’, I.Yu. Ermolenko, N.D. Sakhnenko, S.I. Zyubanova, Yu.I. Sachanova, 2017, published in Elektronnaya Obrabotka Materialov, 2017, No. 6, pp. 16–23.

About this article

Cite this article

Ved’, M.V., Ermolenko, I.Y., Sakhnenko, N.D. et al. Methods for controlling the composition and morphology of electrodeposited Fe–Mo and Fe–Co–Mo coatings. Surf. Engin. Appl.Electrochem. 53, 525–532 (2017). https://doi.org/10.3103/S1068375517060138

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375517060138