Abstract

Cu smelter slag contains more than 40 wt% Fe, mostly in fayalite (Fe2SiO4) phase, as well as oxides of non-ferrous metals such as Cu, Co, Ni, and Zn. In this study, the recovery of Fe from the Cu smelter slag via an electrochemical process in HNO3-based solutions is investigated as an aspect of impurity control by varying both the applied cathodic potential and bath chemistry. The Cu smelter slag was preliminarily reduced to Fe alloy including 1.04 wt% Cu and 0.46 wt% Si via the melting reduction method. The Fe alloy was completely dissolved in a concentrated HNO3 solution for electrochemical reduction of Fe at constant cathodic potentials. NaOH and NH4Cl were added to control the solution pH and suppress the precipitation of α-FeO(OH), respectively. Cu and Si within the produced Fe deposit were at non-detectable levels. The lowest O/Fe weight ratio in the Fe deposit was 0.011 by adding 0.561 M NH4Cl to the HNO3-based solution, indicating that 1.09 wt% oxygen was contained.

Similar content being viewed by others

References

Banza A, Gock E, Kongolo K (2002) Base metals recovery from copper smelter slag by oxidising leaching and solvent extraction. Hydrometallurgy 67:63–69

Yang Z, Rui-lin M, Wang-dong N, Hui W (2010) Selective leaching of base metals from copper smelter slag. Hydrometallurgy 103:25–29

Altundoǧan H, Tümen F (1997) Metal recovery from copper converter slag by roasting with ferric sulphate. Hydrometallurgy 44:261–267

Arslan C, Arslan F (2002) Recovery of copper, cobalt, and zinc from copper smelter and converter slags. Hydrometallurgy 67:1–7

Li L, Wang H, Hu J-H (2010) The study of recovering iron by melting reduction from copper slag. International Conference on Digital Manufacturing and Automation, vol. 2, pp 823–827

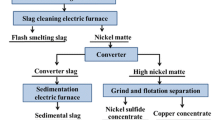

Busolic D, Parada F, Parra R, Sanchez M, Palacios J, Hino M (2011) Recovery of iron from copper flash smelting slags. Miner Process Extr Metall 120:32–36

Sánchez M, Sudbury M (2013) Physiochemical characterization of copper slag and alternatives of friendly environmental management. J Min Metall Sect B 49:161–168

González C, Parra R, Klenovcanova A, Imris I, Sánchez M (2005) Reduction of Chilean copper slags: a case of waste management project. Scand J Metall 34:143–149

Weaver MJ, Anson FC (1975) Simple criteria for distinguishing between inner- and outer-sphere electrode reaction mechanisms. J Am Chem Soc 97:4403–4405

Bongenaar CPM, Remijnse AG, Sluyters-Rehbach M, Sluyters JH (1980) On the selection of the most probable mechanism of the Cd(II) reduction at mercury from 1 M KF solution. J Electroanal Chem 111:139–153

Anderson JL, Shain I (1978) Cyclic voltammetric studies of ionic strength and nitrate ion dependence of copper(I1) reduction in acidic aqueous nitrate and perchlorate solutions. Anal Chem 50:163–171

Haupt S, Strehblow H-H (1987) Corrosion, layer formation, and oxide reduction of passive iron in alkaline solution: a combined electrochemical and surface analytical study. Langmuir 3:873–885

Melendres CA, Pankuch M, Li YS, Knight RL (1992) Surface enhanced Raman spectroelectrochemical studies of the corrosion films on iron and chromium in aqueous solution environments. Electrochim Acta 37:2747–2754

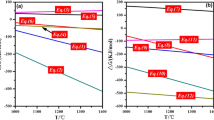

Pourbaix M (1966) Atlas of electrochemical equilibria in aqueous solutions. Pergamon Press Ltd., Oxford, pp 458–463

Yuan B, Kongstein OE, Haarberg GM (2009) Electrowinning of iron in aqueous alkaline solution using a rotating cathode. J Electrochem Soc 156:D64–D69

Mostad E, Rolseth S, Thonstad J (2008) Electrowinning of iron from sulphate solutions. Hydrometallurgy 90:213–220

Pilgrim RF, Ingraham TR (1967) Thermodynamics of the chlorination of iron, cobalt, nickel and copper sulphides. Can Metall Q 6:39–54

Lee CT, Ryoo YH, Kang WK, Paik Y-H (1985) Chlorination of iron oxide with ammonium chloride (II). Hwahak Konghak 23:1–8

Frini A, Maaoui ME (1997) Kinetics of the formation of goethite in the presence of sulfate and chlorides of monovalent cations. J Colloid Interface Sci 190:269–277

Acknowledgments

This work was co-supported by the R&D Center for Valuable Recycling (Global-Top Environmental Technology Development Program) funded by the Ministry of Environment (Project No.: 11-C20-IR), and by the National Research Foundation of Korea Grant funded by the Korean Government (NRF-2013R1A1A2010120).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J., Kim, S. & Shin, D. Electrolytic recovery of Fe from Cu smelter slag in nitric acid solution. J Appl Electrochem 45, 281–288 (2015). https://doi.org/10.1007/s10800-015-0797-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-015-0797-0