Abstract

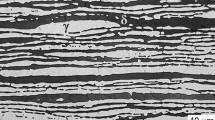

Precipitation of chromium nitrides during cooling from temperatures in the range 1373 K to 1523 K (1100 °C to 1250 °C) has been studied for the super duplex stainless steel 2507 (UNS S32750). Characterization with optical, scanning and transmission electron microscopy was combined to quantify the precipitation process. Primarily Cr2N nitrides were found to precipitate with a high density in the interior of ferrite grains. An increased cooling rate and/or an increased austenite spacing clearly promoted nitride formation, resulting in precipitation within a higher fraction of the ferrite grains, and lager nitride particles. Furthermore, formation of the meta-stable CrN was induced by higher cooling rates. The toughness seemed unaffected by nitrides. A slight decrease in pitting resistance was, however, noticed for quenched samples with large amounts of precipitates. The limited adverse effect on pitting resistance is attributed to the small size (~200 nm) of most nitrides. Slower cooling of duplex stainless steels to allow nitrogen partitioning is suggested in order to avoid large nitrides, and thereby produce a size distribution with a smaller detrimental effect on pitting resistance.

Similar content being viewed by others

References

J. O. Nilsson: Mater. Sci. Technol., 1992, vol. 8, pp. 685–700.

S. Hertzman, B. Brolund, and P. Ferreira: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 277–85.

T. H. Chen and J. R. Yang: Mater. Sci. Eng. A, 2002, vol. 338, pp. 166–81.

J. Liao: ISIJ Int., 2001, vol. 41, pp. 460–67.

R.F.A. Jargelius-Pettersson, S. Hertzman, P. Szakalos, and P.J. Ferreira: Proc. Conf. Duplex Stainless Steels’94, Glasgow, Scotland, 1994, pp. 461–72.

J. O. Nilsson and A. Wilson: Mater. Sci. Technol., 1993, vol. 9, pp. 545–54.

N. Sathirachinda, R. Pettersson, S. Wessman, U. Kivisäkk, and J. Pan: Electrochim. Acta, 2011, vol. 56, pp. 1792–98.

E. Bettini and U. Kivisäkk: Int. J. Electrochem. Sci., 2014, vol. 9, pp. 61–80.

E. M. Westin, M. M. Johansson, and R. F. A. Pettersson: Weld. World, 2013, vol. 4, pp. 467–76.

S. Wessman, A. Wilson, S. Hertzman, and R. Pettersson: Steel Res. Int., 2013, vol. 84, pp. 1126–37.

ASTM International: Test Method for Determining Volume Fraction by Systematic Manual Point Count, ASTM E562, 2011.

Det Norske Veritas: Design of Duplex Stainless Steel Subsea Equipment Exposed to Cathodic Protection, Recommended Practice DNV-RP-F112, 2008.

ASTM International: Test Method for Electrochemical Critical Pitting Temperature Testing of Stainless Steels, ASTM G 150, Outokumpu Stainless Steel Oy, 2013.

Espoo: Outokumpu Corrosion Handbook, 10th ed., Outokumpu Stainless Steel Oy, 2009.

S. Hertzman, W. Roberts, and M. Lindenmo: Proc. Conf. Duplex Stainless Steels’86, The Hague, The Netherlands, 1986, pp. 257–67.

B. Mortimer, P. Grieveson, and K. H. Jack: Scand. J. Metall., 1972, vol. 1, pp. 203–09.

K. A. Bywater and D. J. Dyson: Met. Sci J., 1975, vol. 9, pp. 155–62.

A. J. Ramirez, J. C. Lippold and S. D. Brandi: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1575–97.

J. O. Andersson, T. Helander, and L. Höglund: CALPHAD, 2002, vol. 26, pp. 273–312.

N. Sathirachinda, R. Pettersson, S. Wessman, and J. Pan: Corros. Sci., 2010, vol. 52, pp. 179–86.

E. Bettini, U. Kivisäkk, C. Leygraf, and J. Pan: Electrochim. Acta, 2013, vol. 113, pp. 280–89.

C.-O. A. Olsson: Proc. Conf. Duplex Stainless Steels’94, Glasgow, Scotland, 1994, pp. 83–94.

NORSOK Standard: M-650 Qualification of Manufacturers of Special Materials, 2004, p. 5.

Acknowledgment

This work was performed within the Strategiskt Stålforskningsprogram 2007–2012, administered by Jernkontoret, as part of the project “PREDUP - Prediction, verification and consequences of duplex microstructures”. The project was funded by the Swedish government agency for innovation systems (VINNOVA), and the participating companies AB Sandvik Materials Technology and Outokumpu Stainless AB. Additional funding for work with the manuscript was kindly supplied by Hugo Carlssons Stiftelse. The collaboration with the VINN Excellence Centre Hero-m is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 6, 2014.

Rights and permissions

About this article

Cite this article

Pettersson, N., Pettersson, R.F.A. & Wessman, S. Precipitation of Chromium Nitrides in the Super Duplex Stainless Steel 2507. Metall Mater Trans A 46, 1062–1072 (2015). https://doi.org/10.1007/s11661-014-2718-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2718-y