Abstract

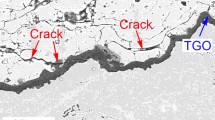

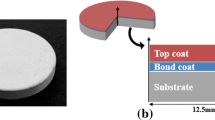

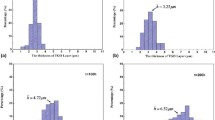

It is critical for thermal barrier coating (TBC) development that a testing method be used to understand the potential and limitation of a coating’s durability and integrity under gas turbine engine operating conditions. To this end, a TBC-coated button is tested using a laser high-heat flux facility. The ceramic coating is ZrO2-8 wt.% Y2O3 applied via the air plasma spraying process on top of a NiCoCrAlY bond coating and an Inconel alloy 617 substrate button of 25.4 mm diameter. The coated button is subject to precisely controlled laser heating on the top side (1150 °C) and a temperature gradient of 63.9 °C/mm through the button overall thickness. The coated button lasts 160.9 h or 570 cycles of laser heating. The void fraction change before and after the test, the thermal conductivity change during the laser test and the failure assessment are presented. After the test, significant horizontal cracks exist in the top coating close to the thermally grown oxide (TGO) layer and near the button center. Based on the cracks and the TGO layer geometry, the stress intensity factor and strain energy release rate are computed. The combined experimental and computational approach can lead to a TBC lifetime model.

Similar content being viewed by others

Abbreviations

- APS:

-

Air plasma spraying

- BC:

-

Bond coating

- C p :

-

Specific heat

- E :

-

Young’s modulus

- FWHM:

-

Full-width at half-maximum

- G :

-

Strain energy release rate

- K :

-

Stress intensity factor

- k n :

-

Normalized thermal conductivity

- k :

-

Thermal conductivity

- SEM:

-

Scanning electron microscope

- SUB:

-

Substrate superalloy

- TBC:

-

Thermal barrier coatings

- TC:

-

Top coating

- TGO:

-

Thermally grown oxides

- T :

-

Temperature

- T H :

-

Hot side or top side of button temperature

- T L :

-

Cold side or bottom side of button substrate temperature

- YSZ:

-

Yttria stabilized zirconia

- α :

-

Coefficient of thermal expansion

- ρ :

-

Density

- v :

-

Poisson’s ratio

References

V. Viswanathan, G. Dwivedi, and S. Sampath, Multilayer, Multi-materials Thermal Barrier Coating Systems: Design, Synthesis, and Performance Assessment, J. Am. Ceram. Soc., 2015, 98(6), p 1769-1777

M.J. Smith, J. Scheibel, D. Classen, S. Paschke, S. Elbel, K. Fick, and D. Carlson, Thermal Barrier Coating Validation Testing for Industrial Gas Turbine Combustion Hardware, in ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, June 16-20, 2014 (Dusseldorf, Germany), International Gas Turbine Institute, 2014, GT2014-26359

A. Feuerstein, J. Knapp, T. Taylor, A. Ashary, A. Bolcavage, and N. Hitchman, Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: a Review, J. Thermal Spray Technol., 2008, 17(2), p 199-213. https://doi.org/10.1007/s11666-007-9148-y

Inconel Alloy 617, http://www.specialmetals.com/assets/smc/documents/alloys/inconel/inconel-alloy-617.pdf, Accessed on 31 Jan 2019

R.A. Miller, and C.E. Lowell, Failure Mechanisms of Thermal Barrier Coatings Exposed to Elevated Temperatures. Thin Solid Films 95, 265–273 (1982). Also NASA TM-1982-82905

A.H. Bartlett and R.D. Maschio, Failure Mechanisms of a Zirconia-8 wt% Yttria Thermal Barrier Coating, J. Am. Ceram. Soc., 1995, 78, p 1018-1024

N.M. Yanar, The Failure of Thermal Barrier Coatings at Elevated Temperatures, Ph.D. Dissertation, Univ of Pittsburgh, 2004

R. Eriksson, and K.R. Jonnalagadda, A Study on Crack Configurations in Thermal Barrier Coatings, in ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, June 26-30, 2017 (Charlotte, USA), International Gas Turbine Institute, 2017, GT2017-63610

J.P. Feist, P.Y. Sollazzo, C. Pilgrim, and J.R. Nicholls, Operation of a Burner Rig for Thermal Gradient Cycling of Thermal Barrier Coatings, in ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, June 16-20, 2014 (Dusseldorf, Germany), International Gas Turbine Institute, 2014, GT2014-26325

A.M. Kanury, Chapter 8 Flames in Premixed Gases, Introduction to Combustion Phenomena, 3rd ed., Gordon & Breach, New York, 1982

M.H. McCay, P.-f. Hsu, D.E. Croy, D. Moreno, and M. Zhang, The Fabrication, High Heat Flux Testing, and Failure Analysis of Thermal Barrier Coatings for Power Generation Gas Turbines, in ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, June 26-30, 2017 (Charlotte, USA), International Gas Turbine Institute, 2017, GT2017-63683

D. Zhu and R.A. Miller, Thermal Conductivity and Elastic Modulus Evolution of Thermal Barrier Coatings under High Heat Flux Conditions, J. Thermal Spray Technology, 2000, 9(2), p 175-180

D. Zhu, and R.A. Miller, “Thermal Conductivity of Advanced Ceramic Thermal Barrier Coatings Determined by a Steady-State Laser Heat-Flux Approach,” NASA TM-2004- 213040 & ARL–TR–3262, Cleveland, Ohio, July 2004

R.S. Lima, B.R. Marple, and P. Marcoux, Thermal Gradient Behavior of TBCs Subjected to a Laser Gradient Test Rig: simulating an Air-to-Air Combat Flight, J. Thermal Spray Technol., 2016, 25(1–2), p 282-290. https://doi.org/10.1007/s11666-015-0311-6

LabVIEW, National Instruments, 11500 N Mopac Expwy, Austin, TX 78759, USA

The Ircon Modline 3, IRCON, Inc., Santa Cruz, CA 95060, USA

J.I. Eldridge and C.M. Spuckler, Determination of Scattering and Absorption Coefficients for Plasma-Sprayed Yttria-Stabilized Zirconia Thermal Barrier Coatings at Elevated Temperatures, J. Am. Ceram. Soc., 2009, 92(10), p 2276-2285

Mikron Model MI-SQ5, LumaSense Technologies, Inc., 3301 Leonard Court, Santa Clara, CA 95054, USA

MATLAB, MathWorks, 1 Apple Hill Drive, Natick, MA 01760, USA

Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coating, E2109-01, ASTM Standards, ASTM, 2014

M.A. Helminiak, N.M. Yanar, F.S. Pettie, T.A. Taylor, and G.H. Meier, The Behavior of High-Purity, Low-Density Air Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2009, 204, p 793-796

G.C. Chang, W. Phucharoen, and R.A. Miller, Behavior of Thermal Barrier Coatings for Advanced Gas Turbine Blades, Surf. Coat. Technol., 1987, 30(1), p 13-28

C.H. Hsueh and E.R. Fuller, Residual Stresses in Thermal Barrier Coatings: Effect of Interface Asperity Curvature/Height and Oxide Thickness, Mat. Sci. Eng. A, 2000, 283(1–2), p 46-55

C.H. Hsueh and E.R. Fuller, Analytical Modeling of Oxide Thickness Effects on Residual Stresses in Thermal Barrier Coatings, Scripta Mat, 2000, 42(8), p 781-787

M. Gupta, Design of Thermal Barrier Coatings: A Modelling Approach, Springer, Berlin, 2015

J. Aktaa, K. Sfar, and R. Munz, Assessment of TBC Systems Failure Mechanisms using a Fracture Mechanics Approach, Acta Mat., 2006, 53(16), p 4399-4413

M. Martena, D. Botto, P. Fino, S. Sabbadini, M.M. Gola, and C. Badini, Modeling of TBC System Failure: Stress Distribution as a Function of TGO Thickness and Thermal Expansion Mismatch, Engr Fail. Anal., 2006, 13(3), p 409-426

M. Gupta, K. Skogsberg, and P. Nylén, Influence of Topcoat-Bondcoat Interface Roughness on Stresses and Lifetime in Thermal Barrier Coatings, J. Thermal Spray Technol., 2014, 23(1–2), p 170-181. https://doi.org/10.1007/s11666-013-0022-9

M. Gupta, R. Eriksson, U. Sand, and P. Nylén, A Diffusion-Based Oxide Layer Growth Model Using Real Interface Roughness in Thermal Barrier Coatings for Lifetime Assessment, Surf. Coat. Technol., 2015, 271(15), p 181-191

ANSYS, Inc., 2600 ANSYS Drive, Canonsburg, PA 15317, USA

Properties: Alumina-Aluminium Oxide-Al2O3—A Refractory Ceramic Oxide. https://www.azom.com/properties.aspx?ArticleID=52. Accessed 31 Jan 2019

H. Zeng, J. Fang, W. Xu, Z. Zhao, and L. Wang, Thermomechanical Modeling of A Single Splat Solidification in Plasma Spraying, J. Achiev. Mater. Manuf. Eng., 2006, 18(1–2), p 327-330

K. Kim, D. Lee, and H. Cho, Lifetime Prediction of Film Cooling Systems with and without Thermal Barrier Coating, Int. J. Fluid Mach. Syst., 2010, 3(2), p 204-210

Zirconia—Stabilized with Yttria—Online Catalogue Source—Supplier of Research Materials in Small Quantities—Goodfellow. http://www.goodfellow.com/E/Zirconia-stabilised-with-Yttria.html. Accessed 31 Jan 2019

G.M. Smith, M. Resnick, B. Kjellman, J. Wigren, G. Dwivedi, and S. Sampath, Orientation-dependent mechanical and thermal properties of plasma-sprayed ceramics, J. Am. Ceram. Soc., 2018, 101, p 2471-2481

S.R. Choi, D. Zhu, and R.A. Miller, Effect of Sintering on Mechanical and Physical Properties of Plasma-Sprayed Thermal Barrier Coatings, NASA TM-2004-212625, April 2004

R. Vaßen, S. Giesen, and D. Stover, Lifetime of Plasma Sprayed Thermal Barrier Coatings: Comparison of Numerical and Experimental Results, J. Thermal Spray Tech., 2009, 18(5–6), p 835-845

Y.S. Wu, P.-f. Hsu, Y. Wang, and M.H. McCay, Finite Element Analysis of Cracks in the Thermal Barrier Coatings, 2019, under preparation.

Acknowledgments

The authors wish to acknowledge the support of laser high-heat flux testing by Shanghai Electric Gas Turbine Co. Ltd. The support of the numerical study is provided by Florida Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Y., Hsu, Pf., Wang, Y. et al. Laser Thermal Gradient Testing and Fracture Mechanics Study of a Thermal Barrier Coating. J Therm Spray Tech 28, 1239–1251 (2019). https://doi.org/10.1007/s11666-019-00879-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00879-9