Abstract

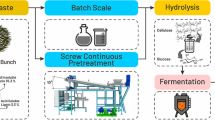

Tea is one of the most commonly consumed beverages in the worldwide. Therefore, spent tea leaves (STL) are abundant low-cost lignocellulosic materials and can be evaluated as a carbon source for the production of value-added products by fermentation. The aim of this study was to optimize the dilute acid and alkaline pretreatment conditions of STL. The optimal conditions were determined by response surface method (RSM) in terms of fermentable sugars concentration (FSC) and total phenolics concentration (PHC). Independent variables were selected as temperature (115–135 °C), pretreatment time (20–60 min), solid-to-liquid ratio (1:8–1:16 w/v), and dilute acid (1–5% v/v) or alkaline (1–3 N) ratio. It was found that the optimum conditions for dilute acid pretreatment were 131.67 °C, 20 min, 1:10.26 w/v, and 1.58% v/v, which yielded as 21.56 g/L, 0.228 g/g, and 1.53 g/L for FSC, FSY, and PHC, respectively. Nevertheless, the best dilute alkaline pretreatment conditions were 116.42 °C, 20 min, 1:11.23 w/v, and 1.68 N, which achieved as 28.18 g/L, 0.316 g/g, and 5.26 g/L for FSC, FSY, and PHC, respectively. Nevertheless, based on the statistical evaluation, it was found that RSM models victoriously fitted the experimental data related to the pretreatment of STL. Consequently, acid and alkaline pretreated-STL can be considered as suitable carbon source for value-added products’ production by fermentation.

Similar content being viewed by others

References

Rajendran K, Drielak E, Varma VS, Muthusamy S, Kumar G (2017) Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production–a review. Biomass Convers Bioref:1–13

Arenas-Cárdenas P, López-López A, Moeller-Chávez GE, León-Becerril E (2017) Current pretreatments of lignocellulosic residues in the production of bioethanol. Waste Biomass Valoriz 8(1):161–181. https://doi.org/10.1007/s12649-016-9559-4

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38(4):522–550. https://doi.org/10.1016/j.pecs.2012.02.002

Sarker TC, Azam SMGG, Bonanomi G (2017) Recent advances in sugarcane industry solid by-products valorization. Waste Biomass Valoriz 8(2):241–266. https://doi.org/10.1007/s12649-016-9665-3

Cheng L, Keener TC, Lee J-Y, Zhou X (2012) Dilute acid pretreatment for cellulosic alcohol production. Biomass Convers Bioref 2(2):169–177. https://doi.org/10.1007/s13399-012-0039-1

Kalogiannis K, Stefanidis S, Marianou A, Michailof C, Kalogianni A, Lappas A (2015) Lignocellulosic biomass fractionation as a pretreatment step for production of fuels and green chemicals. Waste Biomass Valoriz 6(5):781–790. https://doi.org/10.1007/s12649-015-9387-y

Alvira P, Tomás-Pejó E, Ballesteros M, Negro M (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861. https://doi.org/10.1016/j.biortech.2009.11.093

Steinbach D, Kruse A, Sauer J (2017) Pretreatment technologies of lignocellulosic biomass in water in view of furfural and 5-hydroxymethylfurfural production-a review. Biomass Convers Bioref:1–28

FAOSTAT (2016) http://faostat3.fao.org/download/Q/QC/E,Accessed 23 Sept 2016.

Germec M, Tarhan K, Yatmaz E, Tetik N, Karhan M, Demirci A, Turhan I (2016) Ultrasound-assisted dilute acid hydrolysis of tea processing waste for production of fermentable sugar. Biotechnol Prog 32(2):393–403

Yilmaz G, Kandemir N, Kinalioglu K (2004) Effects of different pruning intervals on fresh shoot yield and some quality properties of Tea (Camellia sinensis (L.) O. Kuntze) in Turkey. Pak J Biol Sci 7(7):1208–1212

Yücel Y, Göycıncık S (2015) Optimization of ethanol production from spent tea waste by Saccharomyces cerevisiae using statistical experimental designs. Biomass Convers Bioref 5(3):247–255. https://doi.org/10.1007/s13399-014-0138-2

Hameed BH (2009) Spent tea leaves: a new non-conventional and low-cost adsorbent for removal of basic dye from aqueous solutions. J Hazard Mater 161(2):753–759. https://doi.org/10.1016/j.jhazmat.2008.04.019

Tzeng J-H, Weng C-H, Huang J-W, Lin Y-H, Lai C-W, Lin Y-T (2015) Spent tea leaves: a new non-conventional and low-cost biosorbent for ethylene removal. Int Biodeterior Biodegrad 104:67–73. https://doi.org/10.1016/j.ibiod.2015.05.012

Germec M, Kartal FK, Bilgic M, Ilgin M, Ilhan E, Güldali H, Isci A, Turhan I (2016) Ethanol production from rice hull using Pichia stipitis and optimization of acid pretreatment and detoxification processes. Biotechnol Prog 32(4):872–882. https://doi.org/10.1002/btpr.2275

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428. https://doi.org/10.1021/ac60147a030

Germec M, Demirel F, Tas N, Ozcan A, Yilmazer C, Onuk Z, Turhan I (2017) Microwave-assisted dilute acid pretreatment of different agricultural bioresources for fermentable sugar production. Cellulose 24(10):4337–4353

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol 299:152–178

Chai T, Draxler RR (2014) Root mean square error (RMSE) or mean absolute error (MAE)?–arguments against avoiding RMSE in the literature. Geosci Model Dev 7(3):1247–1250. https://doi.org/10.5194/gmd-7-1247-2014

Cayré ME, Vignolo G, Garro O (2003) Modeling lactic acid bacteria growth in vacuum-packaged cooked meat emulsions stored at three temperatures. Food Microbiol 20(5):561–566. https://doi.org/10.1016/S0740-0020(02)00154-5

Ross T (1996) Indices for performance evaluation of predictive models in food microbiology. J Appl Microbiol 81(5):501–508. https://doi.org/10.1111/j.1365-2672.1996.tb01946.x

Marzialetti T, Valenzuela Olarte MB, Sievers C, Hoskins TJ, Agrawal PK, Jones CW (2008) Dilute acid hydrolysis of Loblolly pine: a comprehensive approach. Ind Eng Chem Res 47(19):7131–7140. https://doi.org/10.1021/ie800455f

Yücel Y, Göycıncık S (2015) Optimization and modelling of process conditions using response surface methodology (RSM) for enzymatic saccharification of spent tea waste (STW). Waste Biomass Valoriz 6(6):1077–1084. https://doi.org/10.1007/s12649-015-9395-y

Goel B, Pant D, Kishore V (2001) Two-phase anaerobic digestion of spent tea leaves for biogas and manure generation. Bioresour Technol 80(2):153–156

Mahmood T, Hussain ST (2010) Nanobiotechnology for the production of biofuels from spent tea. Afr J Biotechnol 9(6):858–868

Lazim Z, Mazuin E, Hadibarata T, Yusop Z (2015) The removal of methylene blue and Remazol Brilliant Blue R dyes by using orange peel and spent tea leaves. J Teknol 74:129–135

Zuorro A, Lavecchia R, Medici F, Piga L (2013) Spent tea leaves as a potential low-cost adsorbent for the removal of azo dyes from wastewater. Chem Eng 32:19–24

Ansari R, Khanesar PH (2013) Application of spent tea leaves as an efficient low cost biosorbent for removal of anionic surfactants from aqueous solutions. Eur Chem Bull 2(5):283–289

Lavecchia R, Pugliese A, Zuorro A (2010) Removal of lead from aqueous solutions by spent tea leaves. Chem Eng Trans 19:73–78

Mohammed AA, Abed FI, Al-Musawi TJ (2016) Biosorption of Pb (II) from aqueous solution by spent black tea leaves and separation by flotation. Desalin Water Treat 57(5):2028–2039. https://doi.org/10.1080/19443994.2014.982194

Bajpai SK, Jain A (2010) Removal of copper (II) from aqueous solution using spent tea leaves (STL) as a potential sorbent. Water SA 36(3):221–228

Ghosh A, Das P, Sinha K (2015) Modeling of biosorption of Cu (II) by alkali-modified spent tea leaves using response surface methodology (RSM) and artificial neural network (ANN). Appl Water Sci 5(2):191–199

Özbaş EE, Öngen A, Gökçe CE (2013) Removal of astrazon red 6B from aqueous solution using waste tea and spent tea bag. Desalin Water Treat 51(40–42):7523–7535

Akar E, Altinişik A, Seki Y (2013) Using of activated carbon produced from spent tea leaves for the removal of malachite green from aqueous solution. Ecol Eng 52:19–27

Bajpai SK, Jain A (2010) Sorptive removal of crystal violet from aqueous solution using spent tea leaves: part I optimization of sorption conditions and kinetic studies. Acta Chim Slov 57(3):751–757

Agarry S, Ogunleye O, Aworanti O (2013) Biosorption equilibrium, kinetic and thermodynamic modelling of naphthalene removal from aqueous solution onto modified spent tea leaves. Environ Technol 34(7):825–839

Lazim ZM, Zulkifli N, Hadibarata T, Yusop Z (2015) Removal of cresol red and reactive black 5 dyes by using spent tea leaves and sugarcane baggase powder. J Teknol 74(11):147–151

Li L, Li X, Yan C, Guo W, Yang T, Fu J, Tang J, Hu C (2014) Optimization of methyl orange removal from aqueous solution by response surface methodology using spent tea leaves as adsorbent. Front Environ Sci Eng 8(4):496–502. https://doi.org/10.1007/s11783-013-0578-0

Wang T, Qu G, Pei S, Liang D, Hu S (2016) Research on dye wastewater decoloration by pulse discharge plasma combined with charcoal derived from spent tea leaves. Environ Sci Pollut Res 23(13):13448–13457. https://doi.org/10.1007/s11356-016-6520-9

Fadhil AB, Dheyab MM, Abdul-Qader A-QY (2012) Purification of biodiesel using activated carbons produced from spent tea waste. J Assoc Arab Univ Basic Appl Sci 11(1):45–49. https://doi.org/10.1016/j.jaubas.2011.12.001

Weng CH, Lin YT, Chen YJ, Sharma YC (2013) Spent green tea leaves for decolourisation of raw textile industry wastewater. Color Technol 129(4):298–304. https://doi.org/10.1111/cote.12029

Wong S, Lee Y, Ngadi N, Inuwa IM, Mohamed NB (2017) Synthesis of activated carbon from spent tea leaves for aspirin removal. Chinese Journal of Chemical Engineering

Ramdani D (2014) Evaluation of tea and spent tea leaves as additives for their use in ruminant diets. University of Newcastle upon Tyne, United Kingdom

Chen KI, Lo YL, Lio CW, Yu RC, Chou CC, Cheng KC (2013) Enrichment of two isoflavone aglycones in black soymilk by using spent coffee grounds as an immobiliser for β-glucosidase. Food Chem 139(79–85):1–4. https://doi.org/10.1016/j.foodchem.2013.01.093

Germec M, Turhan I, Karhan M, Demirci A (2015) Ethanol production via repeated-batch fermentation from carob pod extract by using Saccharomyces cerevisiae in biofilm reactor. Fuel 161:304–311. https://doi.org/10.1016/j.fuel.2015.08.060

Funding

This study was supported by the Akdeniz University Research Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Germec, M., Bader, N.B. & Turhan, I. Dilute acid and alkaline pretreatment of spent tea leaves to determine the potential of carbon sources. Biomass Conv. Bioref. 8, 529–544 (2018). https://doi.org/10.1007/s13399-018-0301-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-018-0301-2