Abstract

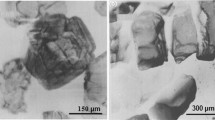

The effects of particle cracking on the strength and ductility of Al-SiCp metal matrix composite material (MMC) was investigated. The composite was manufactured using a simple powder metallurgy (PM) technique of hot pressing followed by hot extrusion. Also, the effects of reinforcement weight fraction and strain rate variations on the strength and ductility of the same composite were examined. It was found that particle cracking plays a significant role in controlling the mechanical properties of the composite. It was shown that particle cracking is possible in an MMC material made with a low strength matrix (commercially pure aluminum), and increases with the increase of reinforcement weight fraction, applied strain rate, and amount of plastic deformation. The yield strength increases as a function of reinforcement weight fraction and to a lesser extent as the strain rate increases. The tensile strength increases at low SiCp weight fractions, then remains constant or decreases as more particles are added to the matrix.

Similar content being viewed by others

References

A.L. Geiger and J.A. Walker: “Advances in Metal Matrix Composites,” J. Metals, 1991, 43, p. 8.

A.W. Urquhart: “Molten Metal MMc and CMC’s,” Adv. Mater. Proc., 1991, 7, p. 25.

M.K. Aghajanian, M.A. Rocazella, J.T. Burke, and S.D. Keck, “Fabrication of Mmc By A Pressureless Infiltration Technique,” J. Mater. Sci., 1991, 26, p. 447.

T.W. Clyne and P.J. Withers, An Introduction to Metal Matrix Composites, Cambridge Univ. Press, Cambridge, UK, 1995.

M.G. McKimpson, and T.E. Scott: “Processing and Properties of MMC Containing Discontinuous Reinforcement,” Mater. Sci. Eng., 1989, A 107, pp. 93–106.

J-Yang and D.D.L. Chung: “Casting Particulate and Fibrous MMC by Vacuum Infiltration of a Liquid Metal under Inert Gas Pressure,” J. Mater. Sci., 1989, 24, p. 3605.

J.M. Chiou and D.D.L. Chung, “Characterization of MMC Fabricated by Vacuum Infiltration of a Liquid Metal under Inert Gas Pressure,” J. Mater. Sci., 1991, 26, p. 2583.

E.J. Lavernia, “Spray Atomized and Codeposited 6061 Al/SiC Composites,” SAMPE Quarterly, 1991, 22(2), pp. 2–12.

Y.B. Lui, S.C. Lim, L. Lu, and M.O. Lai: “Recent Development in the Fabrication of Metal Matrix-Particulate Composites Using Powder Metallurgy Techniques,” J. Mater. Sci., 1994, 29, p. 1999.

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia: “Particulate Reinforced MMC—A Review,” J. Mater. Sci., 1991, 26, p. 1137.

D.L. McDaniels, “Analysis of Stress-Strain, Fracture, and Ductility Behavior of Aluminum Matrix Composites Containing Discontinuous SiC Reinforcement,” Metall. Trans. A, 1985, 16A, p. 1105.

D.L. Davidson: “Tensile Deformation and Fracture Toughness of 2014+15Vol. Pct. SiC Particulate Composite,” Metall. Trans. A, 1991, 22A, p. 113.

C.H.J. Davies, N. Raughunathan, and T. Sheppard: “Structure-Property Relationships of SiC Reinforced Advanced Al-Zn-Mg-Cu Alloy,” Mater. Sci. Technol., 1992, 8, p. 977.

J.N. Hall, J.W. Jones, and A.K. Sachdev: Mater. Sci. Eng., 1994, A 183, p. 69.

J.J. Lewandowski, D.S. Liu, and C. Liu: Script. Metall. Mater., 1991, 25, p. 21.

M. Manoharan and J.J. Lewandowski: “Effect of Reinforcement Size and Matrix Microstructure on the Fracture Properties of an Al-MMC,” Mater. Sci. Eng., 1992, A 150, p. 179.

Y. Flom and R.J. Arsenault: Acta Metall., 1989, 37, p. 2413.

S.V. Kamat, J.P. Hirth, and R. Mehrabian: “Work Hardening Behavior of Alumina Particulate Reinforced 2024 Aluminum Alloy MMC,” Acta Metall., 1989, 37, p. 2395.

Anon.: ASTM-B328, Annual Book of ASTM Standards, ASTM, Philadelphia, PA, 1980.

W.D. Callister, Jr., Materials Science and Engineering, John Wiley & Sons, New York, 1989, p. 95.

D. Lee and D.A. Woodford, in The Inhomogeneity of Plastic Deformation, American Society for Metals, Metals Park, OH, 1973, p. 114.

W.S. Miller and F.J. Humphreys, “Strengthening-Mechanisms in Particulate MMC,” Scripta Metall. Mater., 1991, 25, p. 33.

A. Levy and J.M. Papazian, “Tensile Properties of Short Fiber Reinforced SiC/Al Composites: Part II. Finite Element Analysis,” Metall. Trans A, 21A, 1990, p. 411.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mazen, A.A., Emara, M.M. Effect of particle cracking on the strength and ductility of Al-SiCp powder metallurgy metal matrix composites. J. of Materi Eng and Perform 13, 39–46 (2004). https://doi.org/10.1361/10599490417579

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/10599490417579