Abstract

To enhance multidisciplinary design and simulation of complex systems, MBSE (Model Based Systems Engineering) is a methodology where computer aided graphical modeling authoring tools are used to specify functions and behaviors of the systems. Simulation tools bring about a system behavioral abstraction required for the design of complex products. MBSE enables more robust systems engineering, because it results in models and their associated behavioral abstraction [1].

A research approach for modelling manufacturing systems in the aerospace industry, and in particular for FAL (Final Assembly Line), has been proposed by the authors in several research papers during the last years [2, 3]. Functional and data models have been published and deployed using data structures available from commercial PLM systems [4].

Recently a new approach for modelling manufacturing systems has been coined as an extension of the previous research to introduce MBSE in manufacturing. A new architecture based on 3-Layers Model (3LM) has been defined: a Data layer, an Ontology layer and a Service layer. Ontology layer is the core of the 3LM. The Ontology layer defines: Scope model, Data model, Behavior model and Semantic model, to further instance information from databases. Scope model is mandatory because manufacturing is a large and wide part of the artifact lifecycle and Data model can cover different several uses across it.

This paper presents a preliminary methodology for Models for Manufacturing (MfM) trends and issues that can be addressed in order to support the generation and management of manufacturing ontologies.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Models for Manufacturing (MfM)

- industrial DMU (iDMU)

- Ontologies

- 3-Layers Model (3LM)

- Model-Based Systems Engineering (MBSE)

1 Introduction

The motivation for this preliminary approach to an MfM methodology is to provide MPT (Method, Processes and associated Tools) to help the engineers to perform the Industrial Design and manufacturing of an aerospace product. The MfM methodology aims to provide a set of processes, methods and associated tools to support the discipline of manufacturing in a model-based context.

Currently, in the aerospace industry, the 3D definition of the product using PLM, CAx tools and MBSE models in a huge improvement in the Functional Design processes. Therefore, in the manufacturing side of the lifecycle, despite the use of ERP, PLM, MES CAx tools and bespoke tools that has been improved along the last years modelling is still undergoing.

The novelty of this work relays on the development of a reference framework, the 3LM, based on the definition of a manufacturing ontology and enabling simulation, behaviors and analytical capabilities, capitalizing the Company knowledge. Currently the research is doing in parallel with the development of architecture, prototypes tools and manufacturing use cases. Still it is in preliminary phase.

Following to the rest of the document, Sect. 2 contains more detailed review of the problem to solve. Section 3 is devoted to present a non-exhaustive literature review about MBSE research close-to-industrial research. Section 4 contains the methodology under development, supported by a 3LM, referred to as Data, Ontology and Service layers. Section 5 discloses the discussion and conclusions from this work and to present the topics for further research.

2 Review of MBSE Research Initiatives for Manufacturing

Model-Based Systems Engineering is a methodology that has gained a foothold over the past 10–15 years and continues to be refined and improved today. One of the main goals of MBSE is to substitute the classic 3D centric approach and document-oriented information in favor of a simulated model-oriented definition that has several benefits [5, 6]:

-

The model is the core of the development (requisites, design, and manufacturing).

-

Ability to manage complexity and to capture knowledge.

-

Analysis and trade-off and early detection of issues.

-

Keep consistency between requisites along the lifecycle.

-

Allow flexibility when changes appear.

Bergenthal [12] defines MBE (Model Based Engineering) in the Model Based Engineering final report for US NDIA (National Defense Industrial Association): “an approach to engineering that uses models as an integral part of the technical baseline that includes the requirements, analysis, design, implementation, and verification of a capability, system, and product throughout the lifecycle”, extending MBE to the whole lifecycle.

Frechette [8] defines a Model-based Enterprise: “an organization that applies modeling and simulation technologies to integrate and manage its technical and business processes to define, execute, control, and manage all enterprise processes”, insisting in the extension of MBSE to the whole lifecycle.

MBSE has been worldwide accepted by the aerospace and automotive industry during the last few years [7], with hundreds of development and deployment in the Functional Design processes and with special emphasis in the area of systems design. Several researches, developments, deployments and projects has been conducted using MBSE, but only recently the interest is turning to manufacturing. Industrial Design of the product, manufacturing and assembly, balancing lines, configuration and change management, and many others tasks performed during the serial production phase of the lifecycle are taken the attention of the researchers.

Friedenthal et al. [5] proposed a 2010 status and a 2020 vision on MBSE. Some topics selected for the 2020 vision are applied to manufacturing:

-

Extends to domains beyond engineering to support complex areas.

-

Enable the engineer to focus on abstract modeling of the user domain.

-

Modeling standards supporting high fidelity simulation and real representations.

-

Extensive reuse of model libraries, taxonomies, and design patterns.

-

Standards supporting integration and management across a distributed repository.

The iDMU, as proposed in [14] can be designed under the paradigm of MBSE, and the most relevant potential opportunities are integration of knowledge, reusability, and traceability, reduced costs, higher quality, and decreased time-to-market in addition with the automation of manufacturing document generation.

Kulvatunyou et al. [9] presents several ontologies for industrial problems that have been a topic of research for several years, most of the projects in the EU Horizon 2020 program have adopted ontology as a component and similarly, in the US NIST (National Institute of Standards and Technology), manufacturing projects also have ontology as a component. In fact, reinforces the concept of commonality between the ontologies, long term interoperability between the different engineering, manufacturing, and supply chain disciplines.

NIST organized a workshop to explore the idea of a framework for curating ontologies, an IOF (Industrial Ontologies Foundry) [10]. The goal for the workshop was to identify industry needs, to develop consensus and to identify the issues that need to be addressed to move forward. Workshop participants reported the main reason in seeing an industrial ontology foundry is interoperability, information linking, and formalization of requirements through information constraints, incorporation of business process aspects, and quality and traceability.

Several authors [15,16,17,18] are researching on the development and deployment of MBSE methodologies and tools in manufacturing. Aspects like process planning, human resources, robotics, IoT (Internet of Things) are recently research topics.

Ontologies are in the core of MBSE methodology. According Uschold and Gruninger [19], ontology is the term used to refer to the shared understanding of some domain of interest which embodies some sort of world view with respect to the given domain.

Ontology model development is today a worldwide research topic and ontology Engineering refers to the set of activities that concern the ontology development process and the ontology lifecycle, the methods and methodologies for building ontologies, and the tool suites and languages that support them [20].

3 Problem to Solve

The objective of the presented research work is to propose a MBSE methodology able to be applied along the Industrial Design, Serial Manufacturing and In-Service Support phases of an aerospace artifact lifecycle. Figure 1 shows the typical lifecycle of a commercial aircraft [13]. Despite the Functional Design is a huge human and financial effort, only takes around 10 years with some isolate upgrading efforts along the lifecycle. Production and in-service support takes a long period, around 40 years, covering both Functional and Services Design, manufacturing, assembly, and management of the supply chain, MRO (Maintenance, Repair and Overhaul) and product services activities.

Typical commercial aircraft program lifecycle [13].

As an example, considering the aerospace lifecycle phases [11], there are four main software systems used to generate, manage and exploit the aircraft related data or information: Computer Aided applications (CAx), Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES) and several bespoke and legacy tools.

Aerospace artifact data are dispersed through a number of databases belonging to different software systems (e.g. PLM, ERP, MES, bespoke and legacy systems), which are operated along the lifecycle. Every software system considered has a full vertical approach: Database, Data model and Service. Databases are usually provided by a vendor (Oracle, MySQL, and others). Data model, the core of the system is defined and developed by the provider with little or none user influence. Service is the mathematical, simulations, behaviors or business functions to apply. Even though each system ensures the consistency of its data, the approach fails to ensure a data model consistency along the aerospace artifact whole lifecycle.

Manufacturing is a large and wide part of the lifecycle and covers several different stages with similar models. Nowadays many different software applications are running with interfaces between them without a full common model. Data continuity is devoted to interfaces between the applications, simulation is done partially and consistency with the Company processes is done via customization, legacy software add-ons or Excel sheets.

The proposed solution is the 3LM framework and the MfM methodology and associated tools. It supports splitting functions and data, and creating ontology to define, manage and maintain the Company knowledge.

4 Models for Manufacturing (MfM) Methodology

4.1 3-Layers Model (3LM)

Model-Based for Manufacturing methodology proposed is based on a 3-Layers Model shown in Fig. 2. The 3LM ensures the independence between layers, maintaining both Data Layer and Ontology Layer isolated. The result is independence on the definition of the Ontology, the knowledge of the Company, against Data layer and Services layer. In fact, the 3LM decouples the traditional vertical system developed by the software vendors giving to the users the independence to migrate software services inside the Service Layer easily.

The lower layer, Data layer, collect all the databases and interfaces: legacy databases from the legacy software, databases from the commercial software applications, clouds and data lakes databases and many others. Included in the Data layer are those databases to hold the information instanced using Ontology layer.

The medium layer, the Ontology layer, is the core of the model. It holds all the Company processes and scope, data and semantic models, and the associated simulation or behavior requirements.

The upper layer, Service layer, holds the software services. The behaviors of the different services are defined in the Ontology layer as part of the ontology definition. Service layer holds software as authoring and simulation tools, visualizers, data analytics and dashboard and space design exploration tools. Services are exploited using information stored in the Data layer, instanced through the Ontology layer.

4.2 Ontology

The Ontology layer is the core in the 3LM framework and is where the knowledge of the Company is created, stored, managed and used. Ontology Layer includes Scope model, Data model, Behaviour model and Semantics model. Ontology layer is defined in an agnostic way; it is not linked to any model language or software tools. A survey of the current existing ontology software tools shows that a big amount of tools existing on the market and a significant set of them are frequently used [22]. The MfM methodology states a few declarations:

-

Define an agnostic methodology. Do not have preferred tools or languages.

-

Promote the use of simple modelling tools; simple to write models and extremely easy to share, read, understand and discuss by skilled engineers on the model topic.

-

Establish and assure procedures for creation, enrichment and reuse ontologies.

-

Establish a procedure to manage lifecycle, configuration and effectivity from different parts and objects in the ontologies. Promote the use of a PLM tool to fulfill this requirement.

Scope Model

The first step creating the ontology is the Scope model. It defines the limits where the model works and contains all main Data model objects, and the definition of the simulation behaviors.

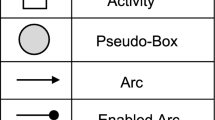

Scope model is a key model for discussion between engineers and should be maintained as simple as possible. Currently, for prototyping purposes, IDEF0 [23] is the tool selected. IDEF0 is a tool widely used in aerospace since decades and cover the requirement “simple to write, easy to read” (Fig. 3).

Data Model

The next step creating the ontology is the Data model. It defines the information managed in the selected scope.

The Scope model contains most of the Data model objects, thus this objects are mapped from the Scope model to the Data model to start building it (Fig. 4).

Using the mapped objects from the Scope model, the engineers can enrich, reuse and complete the Data model. Currently, for prototyping purposes, CMAP [24] is the tool selected. CMAP is a tool widely used to define Data model and cover the requirements “simple to write, easy to read” (Fig. 5).

To support and to manage the objects lifecycle, configuration and effectivity, MfM methodology promotes the use of a PLM system. A PLM system can hold and manage easily ontology objects and let the engineers manage, upgrade, reuse and enrich the objects. An initial prototype, based in a FOSS PLM, is building by the authors.

Behavior Model

The Behavior model defines the simulation or other software defined in the Scope model needed to check the full system. It is still on development and currently it is not included in the MfM methodology.

Semantic Model

The Data model in the ontology should be instance with real data in the prototypes and to run real use cases. Information coming from the databases (commercial applications, bespoke and legacy systems) is defined in different ways, different languages or different formats (i.e. Date in American or European format). Semantic model lets also to maintain connection between models among the lifecycle given digital continuity to the ontologies.

Figure 6 shows a simple example about the application of Semantics in the 3LM. A basic concept in product design, the fillet radius between two planes, is part of a product data model. Corner radius, a useful concept in manufacturing, is part of a manufacturing data model and finally a concept like Rc, is part of a procurement data model. All three concepts have the same meaning: radius: the Semantic model translates and unifies the different definitions, and let the ontology make data instance using radius as a unique concept.

5 Discussion and Further Work

A preliminary approach for a methodology to apply Models for Manufacturing has been proposed and described. A 3LM framework is included on the methodology to assure the full applicability. The methodology is an agnostic methodology, independent of languages or modelling tools.

The feasibility of the applicability of the MBSE methodology to manufacturing has been done using a basic example: a preliminary study applied to Incremental Sheet Forming technology has been developed [21], modelled following the methodology and proposed tools [22].

MfM methodology has been successfully applied to build a prototype in a different use case: an approach to gender analysis in Airbus R&T organization [25].

The research team is working in the improvements of the MfM methodology, the development of the associated tools and the modelling of real manufacturing use cases. The team is working using AGILE for research and development, building prototypes as fast as possible to test and get feedback. As result, research and develop are running in three lines at the same time: MfM methodology, associated tools and prototypes, and use cases. The further MfM methodology tasks planned are:

-

Improve the definition of relationships between Scope model and Data model.

-

Improve the lifecycle management between Scope model and Data model.

-

Define methods to include behavior and simulation from the Scope model definition and from the Data model definition to complete the ontology.

-

Research on “MBSE Design in Context” or “Collaborative MBSE” using MfM during the conceptual phase of the product lifecycle [14].

-

Research on building a virtual manufacturing environment to simulate MfM prototypes and use cases.

References

Holland, O.T.: Model-based systems engineering. In: Loper, M.L. (ed.) Modeling and Simulation in the Systems Engineering Life Cycle. SFMA, pp. 299–306. Springer, London (2015). https://doi.org/10.1007/978-1-4471-5634-5_23

Mas, F., Rios, J., Menendez, J.L., Gomez, A.: A process-oriented approach to modeling the conceptual design of aircraft assembly lines. Int. J. Adv. Manuf. Technol. 67(1–4), 771–784 (2013). https://doi.org/10.1007/s00170-012-4521-5

Mas, F., Oliva, M., Rios, J., Gomez, A., Olmos, V., et al.: PLM based approach to the industrialization of aeronautical assemblies. Procedia Eng. 132, 1045–1052 (2015). https://doi.org/10.1016/j.proeng.2015.12.594

Gómez, A., Rios, J., Mas, F., Vizan, A.: Method and software application to assist in the conceptual design of aircraft final assembly lines. J. Manuf. Syst. 40, 37–53 (2016). https://doi.org/10.1016/j.jmsy.2016.04.002

Friedenthal, S., Griego, R., Sampson, M.: INCOSE model based systems engineering (MBSE) initiative. In: INCOSE International Symposium (2007)

Dickerson, C.E., Mavris, D.: A brief history of models and model based systems engineering and the case for relational orientation. IEEE Syst. J. 7(4), 581–592 (2013)

D’Ambrosio, J., Soremekun, G.: Systems engineering challenges and MBSE opportunities for automotive system design. In: 2017, IEEE International Conference on Systems and Cybernetics, Banff, AB, pp. 2075–2080 (2017)

Frechette, S.: Model based enterprise for manufacturing. In: 2011, 44th CIRP International Conference on Manufacturing Systems, Madison, WI, United States (2011)

Ivezic, N., Kulvatunyou, B., Brandl, D., Cho, H., Yan, L., et al.: Drilling down on Smart Manufacturing – enabling composable apps. Manuf. Lett. 08, 10 (2016)

Ivezic, N., Kulvatunyou, B., Lu, Y., Lee, Y., Lee, J., et al.: OAGi/NIST Workshop on Open Cloud Architecture for Smart Manufacturing. Report number: NISTIR 8124

Ríos, J., Hernández, J.C., Oliva, M., Mas, F.: Product avatar as digital counterpart of a physical individual product: literature review and implications in an aircraft. In: 22nd International Conference on Concurrent Engineering, vol. 2, pp. 657–666. IOS Press. https://doi.org/10.3233/978-1-61499-544-9-657

Bergenthal, J.: Final Report Model Based Engineering (MBE) Subcommittee. NDIA Systems Engineering Division, M&S Committee (2011). https://www.ndia.org/-/media/sites/ndia/meetings-and-events/3187-sullivan/divisions/systems-engineering/modeling-and-simulation/reports/model-based-engineering.ashx. Accessed Mar 2018

European Commission: Aeronautics and Air Transport: Beyond Vision 2020 (Towards 2050). Official Publications of the European Communities, 2010, Luxembourg. http://bookshop.europa.eu. Accessed Mar 2018

Mas, F., Menendez, J.L., Oliva, M., Rios, J., Gomez, A., et al.: iDMU as the Collaborative Engineering engine: research experiences in Airbus. In: International Conference on Engineering, Technology and Innovation (ICE), Bergamo, pp. 1–7 (2014). https://doi.org/10.1109/ICE.2014.6871594

Fiorini, S.R., Bermejo-Alonso, J., Gonçalves, P., de Freitas, E.P., Alarcos, A.O., et al.: A suite of ontologies for robotics and automation [industrial activities]. IEEE Robot. Autom. Mag. 24(1), 8–11 (2017)

Mayer, S., Hodges, J., Dan, Yu., Kritzler, M., Michahelles, F.: An open semantic framework for the industrial Internet of Things. IEEE Intell. Syst. 32(1), 96–101 (2017)

Perini, S., Arena, D., Kiritsis, D., Taisch, M.: An ontology-based model for training evaluation and skill classification in an Industry 4.0 environment. In: Lödding, H., Riedel, R., Thoben, K.-D., von Cieminski, G., Kiritsis, D. (eds.) APMS 2017. IAICT, vol. 513, pp. 314–321. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-66923-6_37

Lundgren, M., Hedlind, M., Kjellberg, T.: Model driven manufacturing process design and managing quality. Procedia CIRP 50(1), 299–304 (2016)

Uschold, M., Gruninger, M.: Ontologies: principles, methods and applications. Knowl. Eng. Rev. 11(2), 93–136 (1996)

Kiritsis, D.: Closed-loop PLM for intelligent products in the era of the Internet of Things. Comput. Aided Des. 43(5), 479–501 (2011)

Morales-Palma, D., Mas, F., Racero, J., Vallellano, C.: A preliminary study of Models for Manufacturing (MfM) applied to Incremental Sheet Forming. In: Chiabert, P., Bouras, A., Noël, F., Ríos, J. (eds.) PLM 2018. IFIP AICT, vol. 540, pp. 284–293. Springer, Cham (2018)

Slimani, T.: Ontology development: a comparing study on tools, languages and formalisms. Indian J. Sci. Technol. 8(24) (2015)

NIST: Integration Definition for Function Modeling (IDEF0). Computer Systems Laboratory of the National Institute of Standards and Technology, December 1993. http://www.idef.com/wp-content/uploads/2016/02/idef0.pdf. Accessed Mar 2018

Cañas, A.J., et al.: Concept maps: integrating knowledge and information visualization. In: Tergan, S.-O., Keller, T. (eds.) Knowledge and Information Visualization. LNCS, vol. 3426, pp. 205–219. Springer, Heidelberg (2005). https://doi.org/10.1007/11510154_11

Arista, R., Mas, F.: A preliminary model-based approach for Gender analysis of Airbus Research Organization. In: IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, pp. 1-6 (2018). https://doi.org/10.1109/ICE.2018.8436319

Acknowledgement

The authors would like to thank Ignacio Eguia, Jose Carlos Molina, Andres Padillo, and other Sevilla University colleagues, Julio Ortegon, and other Cadiz University colleagues, Rebeca Arista, Tamara Borreguero, and other AIRBUS colleagues for their support and contribution during the development of this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 IFIP International Federation for Information Processing

About this paper

Cite this paper

Mas, F., Racero, J., Oliva, M., Morales-Palma, D. (2018). A Preliminary Methodological Approach to Models for Manufacturing (MfM). In: Chiabert, P., Bouras, A., Noël, F., Ríos, J. (eds) Product Lifecycle Management to Support Industry 4.0. PLM 2018. IFIP Advances in Information and Communication Technology, vol 540. Springer, Cham. https://doi.org/10.1007/978-3-030-01614-2_25

Download citation

DOI: https://doi.org/10.1007/978-3-030-01614-2_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-01613-5

Online ISBN: 978-3-030-01614-2

eBook Packages: Computer ScienceComputer Science (R0)